UK-based company

The unit eliminates joints in asphalt repair so extends the life of the pavement, resulting in significant cost savings and less disruption to the road network, according to Thermal Road.

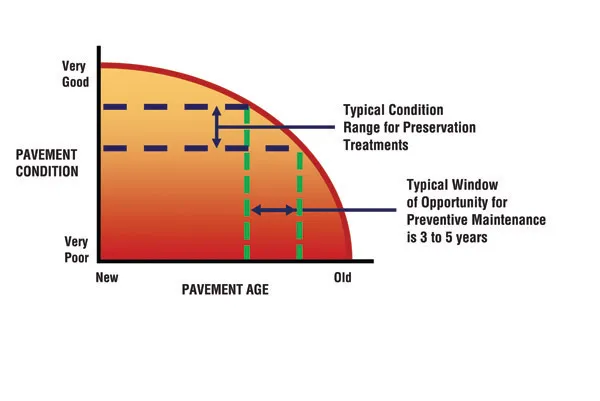

Asphalt lasts for around 20 years before effective deterioration but joints begin to fail after about seven years.

With TRR’s paver-mounted thermal technology, carriageways and other surfaces are seamless from the start of the asphalt laying process so require much less maintenance.

“Our paver-mounted heater allows our clients to replicate echelon paving,” said Aidan Conway, managing director at Thermal Road Repairs.

“They can pave seamlessly, using virgin material or by hot-matching new material with existing asphalt, without inhibiting output from the paving crew. There are other thermal asphalt repair systems in the market but with our technology, clients can operate far more efficiently and cost effectively and deliver a more resilient and superior surface finish, adding significantly to road lifespan.”

A heater, weighing 70kg and measuring 2000mm x 320mm, is mounted onto the side of the paver and controlled heat is pulsed into the joints. Material is heated in front of the screed and the treatment area is compacted across the joint.

“There are hundreds of miles of roads across the country where joints have failed, and continue to do so because the underlying joint is not completely eradicated.

This is a huge inconvenience to drivers and councils who are struggling to maintain good quality surfaces on their limited budgets. Enhanced with our thermal technology, pavers can now permanently eliminate joints so road surfaces can stay better for longer.”

Pat McKay, plant general manager with