A Telestack mobile radial telescopic conveyor will be on display.

Telestack, exhibiting in association with its partners ELB Equipment, has a number of the units operational in Africa where they are used for stockpiling/reclaiming in the pit or the port and for loading vessels at inland river terminals or sea ports.

Telestack says it has designed, manufactured and installed a number of rapid deployment solutions using a range of self-powered mobile conveyors and hopper/feeders that enable miners to qu

August 27, 2013

Read time: 1 min

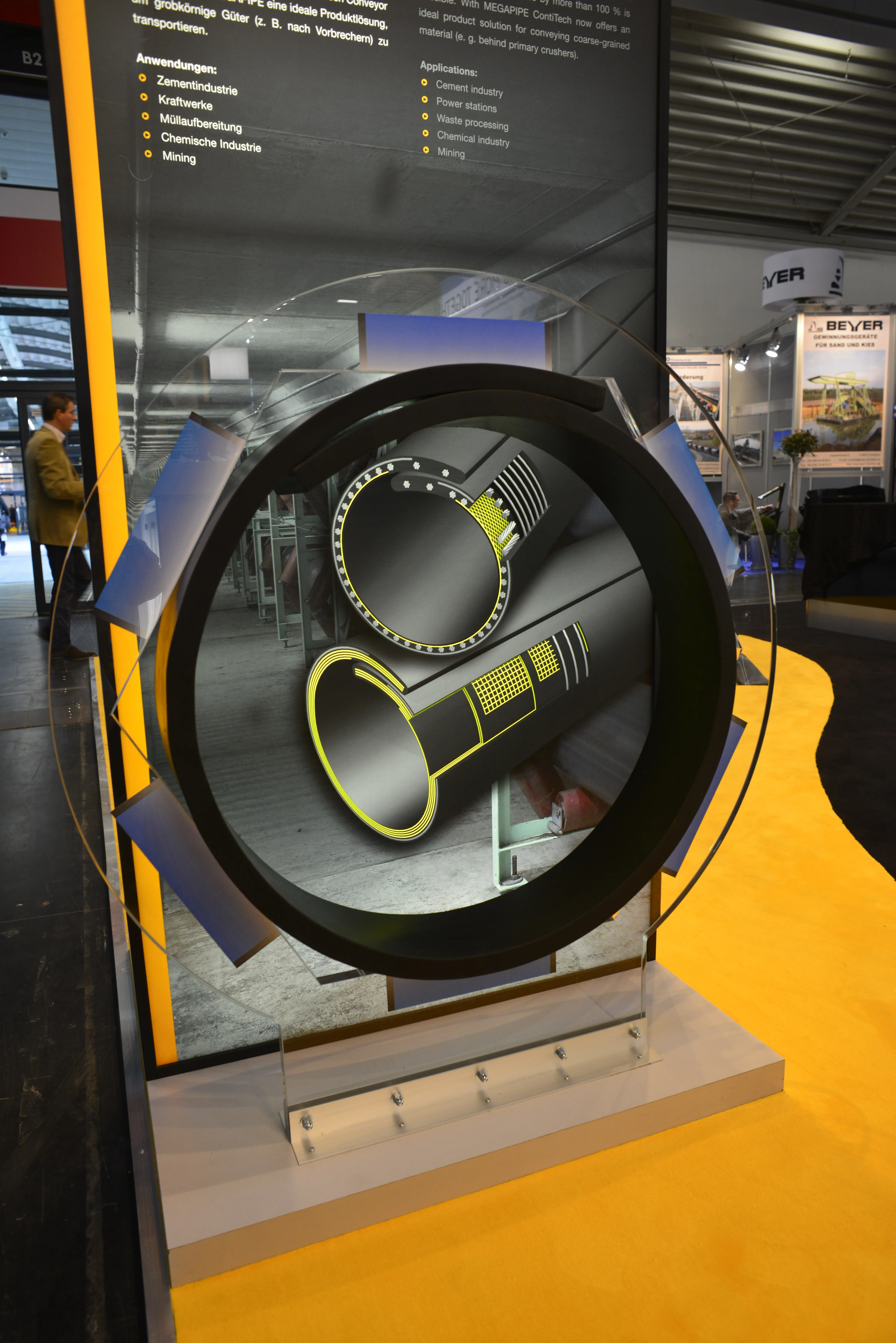

A 3242 Telestack mobile radial telescopic conveyor will be on display.

Telestack, exhibiting in association with its partners ELB Equipment, has a number of the units operational in Africa where they are used for stockpiling/reclaiming in the pit or the port and for loading vessels at inland river terminals or sea ports.

Telestack says it has designed, manufactured and installed a number of rapid deployment solutions using a range of self-powered mobile conveyors and hopper/feeders that enable miners to quickly and cost-effectively stack and reclaim material.

Stand: D.40

Telestack, exhibiting in association with its partners ELB Equipment, has a number of the units operational in Africa where they are used for stockpiling/reclaiming in the pit or the port and for loading vessels at inland river terminals or sea ports.

Telestack says it has designed, manufactured and installed a number of rapid deployment solutions using a range of self-powered mobile conveyors and hopper/feeders that enable miners to quickly and cost-effectively stack and reclaim material.

Stand: D.40