A UK construction firm and asphalt producer

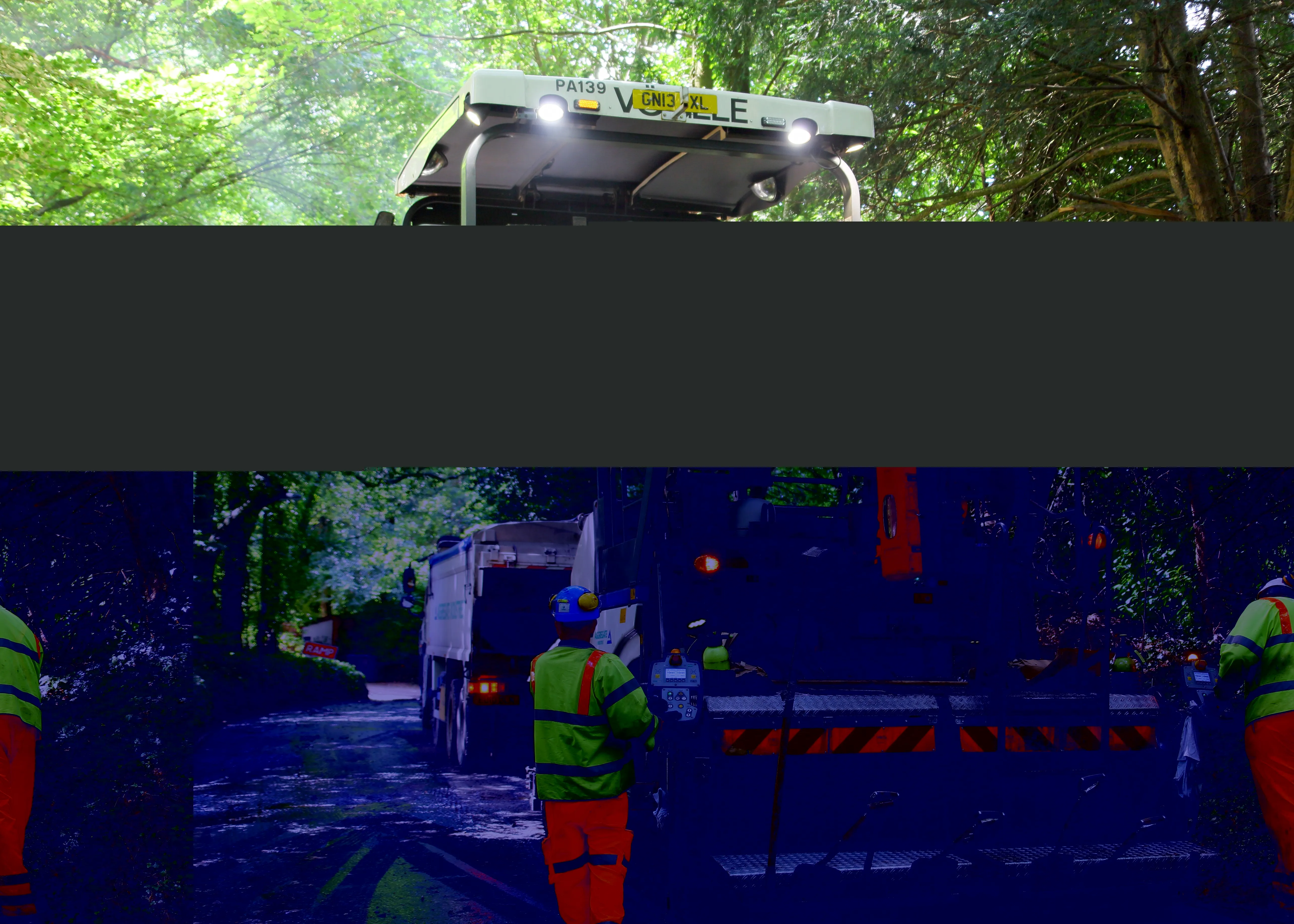

As part of a partnership project between Edinburgh City Council and Midlothian Council to build a new waste treatment facility in the Millerhill area of Midlothian local council, a new link road was required to connect the site to the local road network. Given the high local profile and the sustainable nature of the project, the client was keen that the project met the highest possible standards of sustainability.

The project was scheduled for early February, with low seasonal temperatures expected on site. After detailed consultation with the clients, Tarmac recommended Ultilow as a base and binder course.

Ultilow is a range of low temperature asphalts that comply with the UK’s

Ultilow asphalts perform as well as conventional hot asphalts, but with the added benefits of enhanced workability, improved sustainability and earlier reopening times to traffic.

Around 600 tonnes of Ultilow asphalt base and a further 180 tonnes of binder course was laid over a three-day period. Tarmac said that the lower energy required during production and smaller carbon footprint helped Midlothian Council to achieve a more sustainable outcome for the project.

Ultilow asphalts are produced by either foaming the bitumen or by using a warm mix additive during manufacture. Bitumen foaming occurs when a small quantity of water is injected into hot bitumen and converted into steam. Steam bubbles create a foaming effect that increases the volume of the bitumen and temporarily reduces the viscosity. This allows the bitumen to more fully coat the aggregate.

Warm mix additives are designed to reduce the surface tension of the bitumen itself, allowing the mix to be manufactured and compacted at lower temperatures. Both processes produce comparable warm mix products, for enhanced workability and earlier completion times. Tarmac said that many asphalts in its Ultimate range are now available with Ultilow binder technology.

Ultilow is supplied at temperatures typically 40°C lower than a hot equivalent, reaching appropriate trafficking temperatures quicker than hot asphalt for earlier reopening of carriageways. This feature is particularly valuable when thick construction layers are necessary

Tarmac said that low temperature asphalt is gaining market-share, especially in the United States where they hold around a third of sales. In France, the figure is around 9%. Part of the appeal is that LTA does not need additional paving equipment.