“When it comes to the recycling and reuse of RAP, flux oils are often considered at the same level as rejuvenating additives, but this is not true,” said Iterchmica’s technical director Loretta Venturini. “The two products have a very different impact on the bituminous mixtures in which they are used, but this aspect is often underestimated, even ignored.”

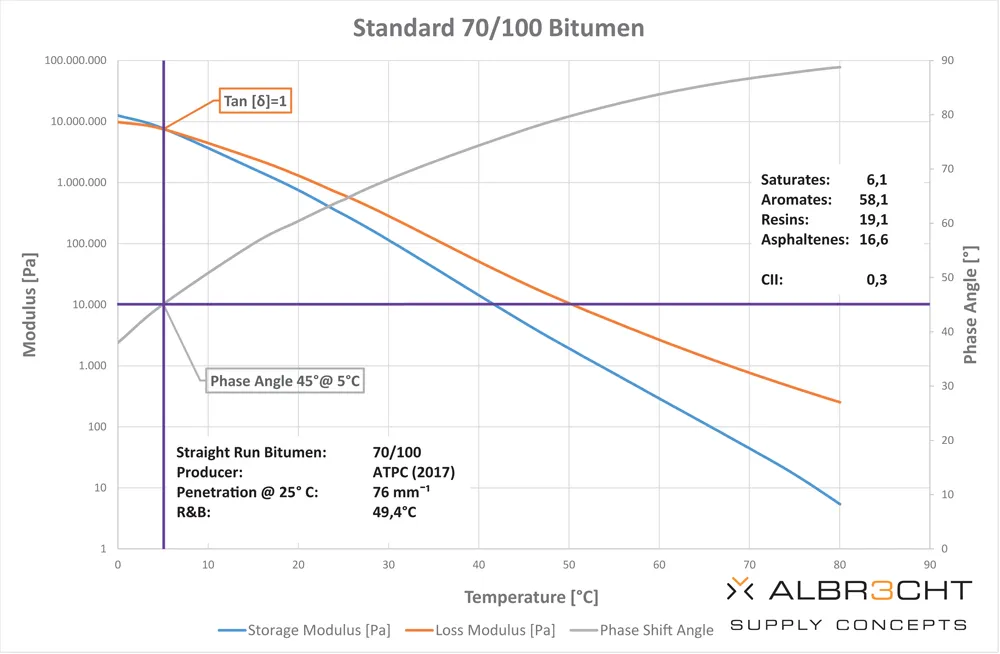

The bitumen in RAP has been subjected to ageing, which means that it will have lost some of its oils, resins and asphaltenes that provide workability, ductility and elasticity to the bitumen. These elements are lost through a variety of means including evaporation, absorption by the aggregates and oxidisation.

In the paper, Iterchimica points out that just because a ‘rejuvenated’ bitumen meets the technical specification, does not mean it will perform as required: “Bitumen with high penetration and low softening point (Ring & Ball) provides the correct viscosity to allow manufacturing and siting, but it cannot compensate the missing chemical compounds and, therefore, it cannot guarantee the useful life of the new pavement.”

Iterchimica engineers carried out a range of tests earlier this year on mixes containing 40% RAP. They compared the properties of a sample with virgin bitumen added, one with added flux oil and a third treated with Iterchimica’s Iterlow-RS, a vegetal-based additive with anti-stripping agent added which can be used at lower temperatures.

Tests with a gyratory compactor showed that the mixture with rejuvenator was more workable than that containing the neat bitumen, whereas the flux oil mixture showed excessive workability. Looking at strength, the mixture with rejuvenator showed small reductions when compared to the neat bitumen mix, whereas the mixture with flux oils was much lower.

Dynamic modulus tests (ITSM) showed that both rejuvenator and flux oil reduced the stiffness of the pavements. Fatigue tests showed the mixture with flux oil achieved load cycles five times higher than the mixture with neat bitumen, and the mix with rejuvenator achieved cycles 10 times higher.

Iterchimica’s report concludes: “The use of a proper rejuvenator increases the service life of the pavement in comparison with the simple use of virgin bitumen.” It goes on to say that where RAP is to be used in a mix, designers must specify adequate technical specifications at an early stage of the design process so that the right form of rejuvenation can be provided. And testing that helps determine the bitumen’s actual properties should be employed.