Singapore-based PRIMACH is now offering an improved range of small to medium sized batching plants. These units are designed to meet the needs of developing markets and can cope with use in remote areas with tough jobsite conditions. Rugged and reliable, the plants can cope with wide variations in climate, while producing high quality hot-mix at low cost according to the firm.

The PRIMACH asphalt mixing plants have been specifically developed to meet customer needs in emergent markets such South East Asi

January 24, 2017

Read time: 2 mins

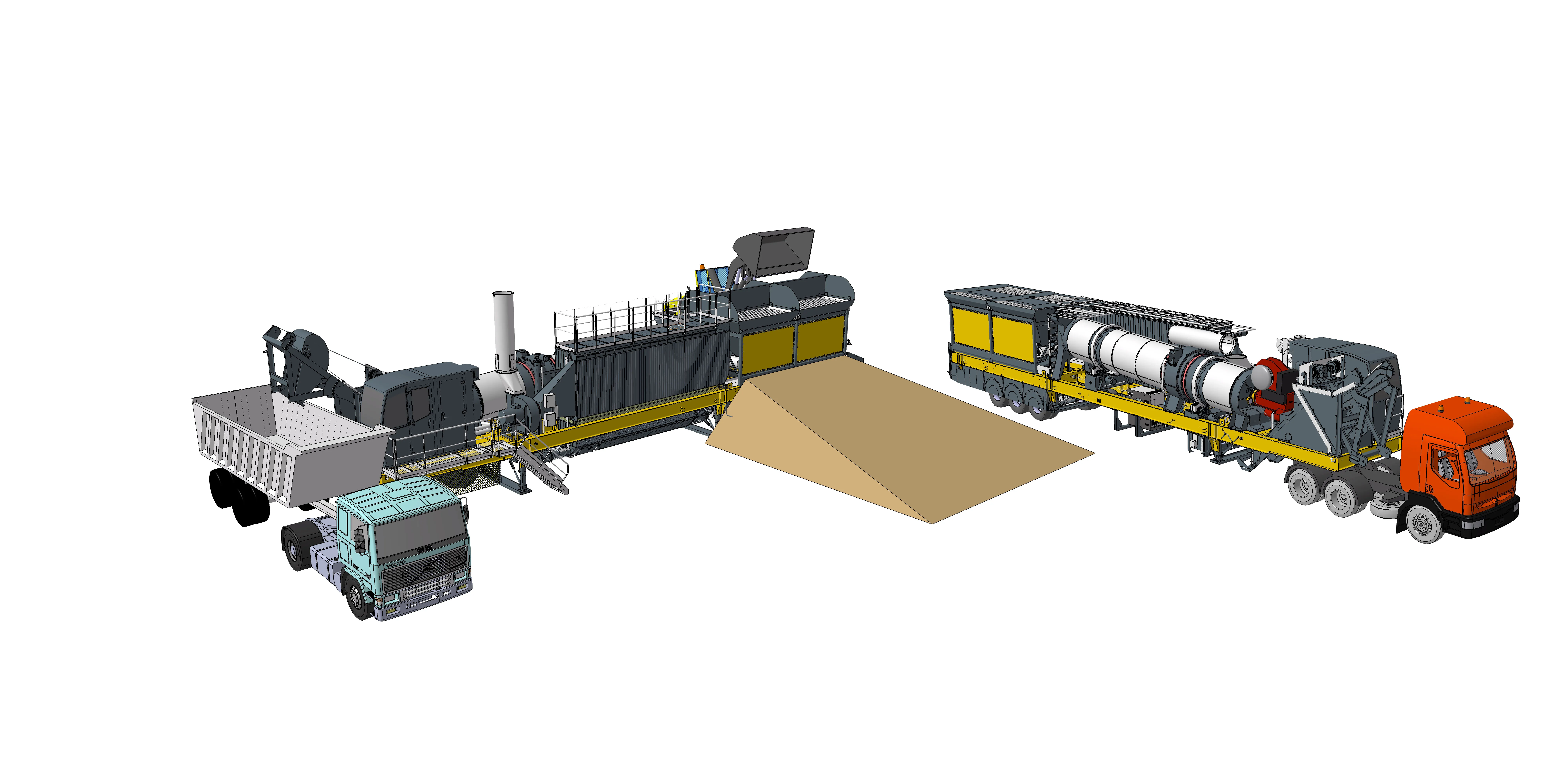

Singapore-based PRIMACH is now offering an improved range of small to medium sized batching plants. These units are designed to meet the needs of developing markets and can cope with use in remote areas with tough jobsite conditions. Rugged and reliable, the plants can cope with wide variations in climate, while producing high quality hot-mix at low cost according to the firm.

The PRIMACH asphalt mixing plants have been specifically developed to meet customer needs in emergent markets such South East Asia, India, Russia, Eastern Europe, the Middle East and Africa. The main structures are said to be compact and mobile and come in modules for easy set up and relocation. High quality components and wear resistant steel have been used for maximum durability and reliability.

The firm has also developed its latest plants to be able to handle RAP and deliver a range of mixes. The environmental profile of the plants are further optimised due to low emissions and a special bag-type dust collection system fitted as standard.

Multiple feed bins are featured, while the firm says that plants have multi-fuel burners that can be run on diesel, heavy oil, natural gas and coal dust. The PLC-operated controls are said to deliver high quality mix to a range of specifications, with the system able to respond quickly to any changes in supply, ambient temperatures or mix requirements for example.

The PRIMACH asphalt mixing plants have been specifically developed to meet customer needs in emergent markets such South East Asia, India, Russia, Eastern Europe, the Middle East and Africa. The main structures are said to be compact and mobile and come in modules for easy set up and relocation. High quality components and wear resistant steel have been used for maximum durability and reliability.

The firm has also developed its latest plants to be able to handle RAP and deliver a range of mixes. The environmental profile of the plants are further optimised due to low emissions and a special bag-type dust collection system fitted as standard.

Multiple feed bins are featured, while the firm says that plants have multi-fuel burners that can be run on diesel, heavy oil, natural gas and coal dust. The PLC-operated controls are said to deliver high quality mix to a range of specifications, with the system able to respond quickly to any changes in supply, ambient temperatures or mix requirements for example.