The importance of selecting correctly-sized and shaped rock products in the construction of roads has a major impact on the longevity of the road’s surface.

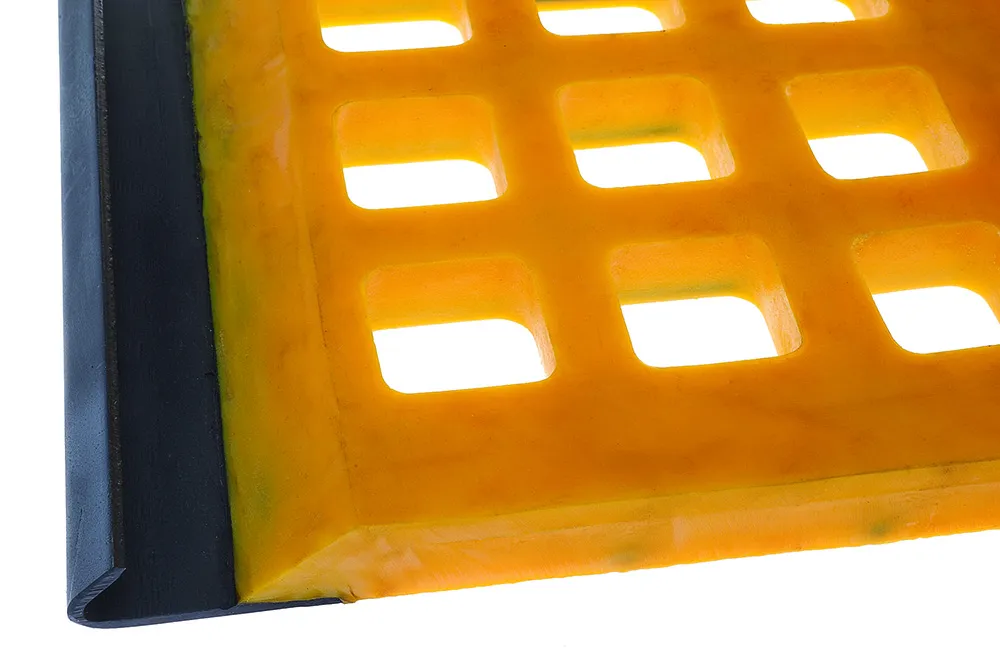

Recently Lewis Quarry took delivery of a new Powerscreen Warrior 2400 mobile screen to produce three end products all supplied to the Pacific Highway upgrade. This large-scale scalper screen is fitted with a metal apron feeder section to accept heavy-duty feed materials and a highly aggressive triple shaft screenbox with a top deck screen media of 100mm punch-plate and a bottom deck of 40mm mesh. The screenbox is configured at 45° with two weights fitted which gives a steady flow of the feed material across the deck. For the project the -40mm is used for sub road-base while the mid-size material, -100mm to +40mm, is used for drainage rock. Finally, the oversized material, +100 to -300mm, is used for small end gabion rock.