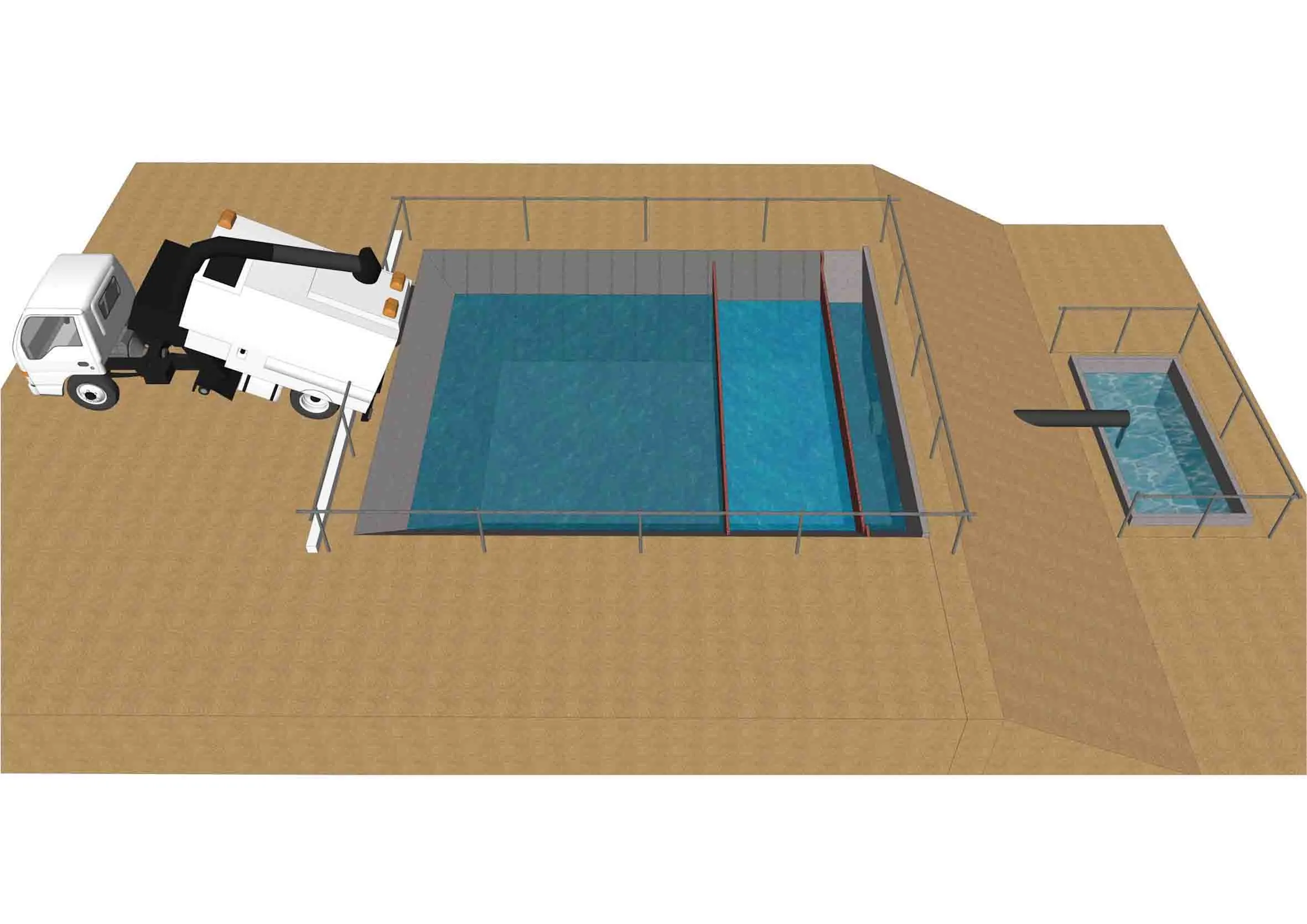

MB Crusher units are proving useful at a demolition site in Guinea. The equipment is helping demolish old port facilities, with the material then being used for base material and road construction at the site. Over US$300 million is being used to renovate the container terminal as well as the damaged yard area.

May 4, 2021

Read time: 1 min

The goal was to remove the self-locking concrete blocks, reinforce the subsoil and lay down new concrete. The aim of the work was to finish on time or even ahead of schedule and avoid disturbance to commercial activities. The contractor selected a BF80.3 crusher bucket from MB, using the unit to crush down concrete blocks to an output size between 0-30mm. This material was then distributed over the substrate, providing a mixture capable of withstanding heavy loads. All of the work was done by reusing waste material and without requiring trucks.