This improves efficiency compared to static media such as woven cloth or synthetic panels. “We understand that no two operations are identical, which is why we configure each screening panel to precisely fit individualised requirements,” said Bernard Betts, president of MAJOR, based in Quebec, Canada, and a Haver & Boecker company.

Flex-Mat delivers increased throughput by providing more open area than traditional panels. The company says that it features up to 40% more screen capacity than traditional woven wire. It also provides up to 50% more than traditional polyurethane and rubber panels, setting a new standard in performance for aggregate, mining and industrial producers.

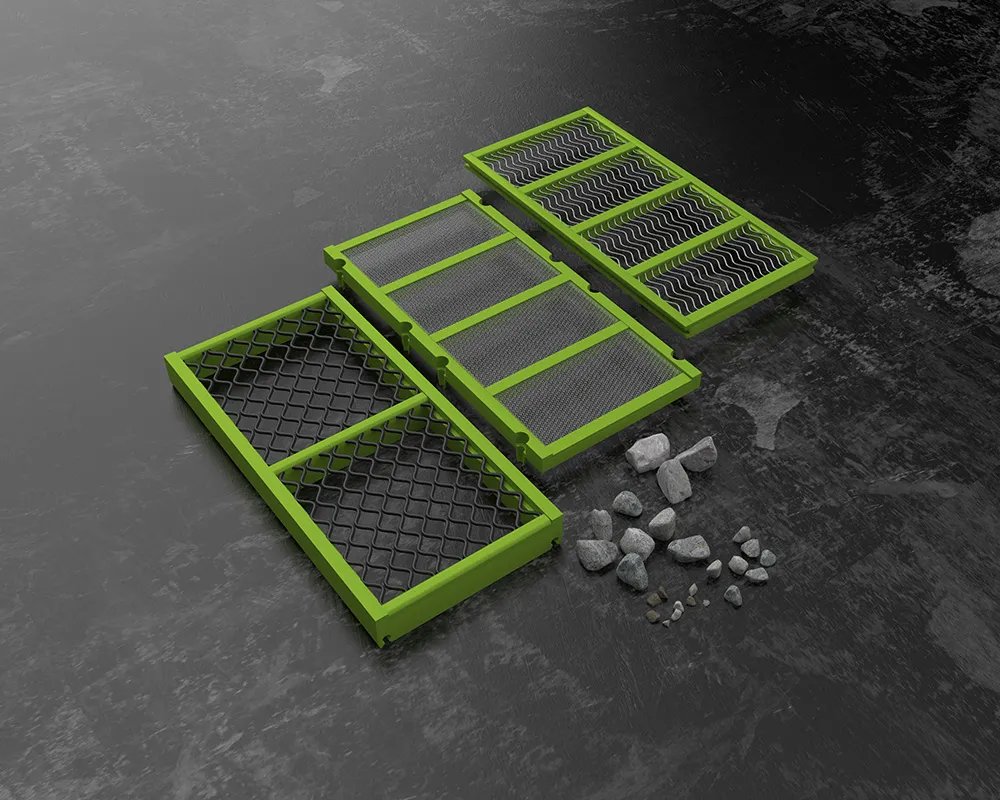

The modular panels are available in three pattern options: the D, S and T series. The D series features a standard square pattern, which is ideal for precise sizing. The S series maximises open area, virtually eliminates blinding and reduces fine contamination. The T series enhances screening for particles below 1.5mm and features small openings to minimise blinding. The screen media is secured through either grooved, step or pin and leg panels.

The efficiency-enhancing characteristics of all Flex-Mat screen media, including modular panels, are created by bonding Optimumwire — the industry’s longest-lasting wire — with distinctive lime green polyurethane strips rather than weaving them. This allows wires to vibrate independently from end to end under material contact. The high frequency of the wires — 8,000 to 10,000 cycles per minute — adds to the vibration of the screen box — 800 to 900 cycles per minute — to speed up material separation and passing.

The increased screening action improves material throughput while virtually eliminating near-size pegging on the top decks and fine material blinding and clogging on the bottom decks, resulting in a lower cost of production per tonne. Additionally, the media offers up to five times longer wear life than traditional woven wire and produces a cleaner retained product.

Flex-Mat modular screen media panels are available in either the patented Optimumwire or 304 stainless steel wire. In addition to modular panels, Flex-Mat is available in tensioned sections for use on crown decks.