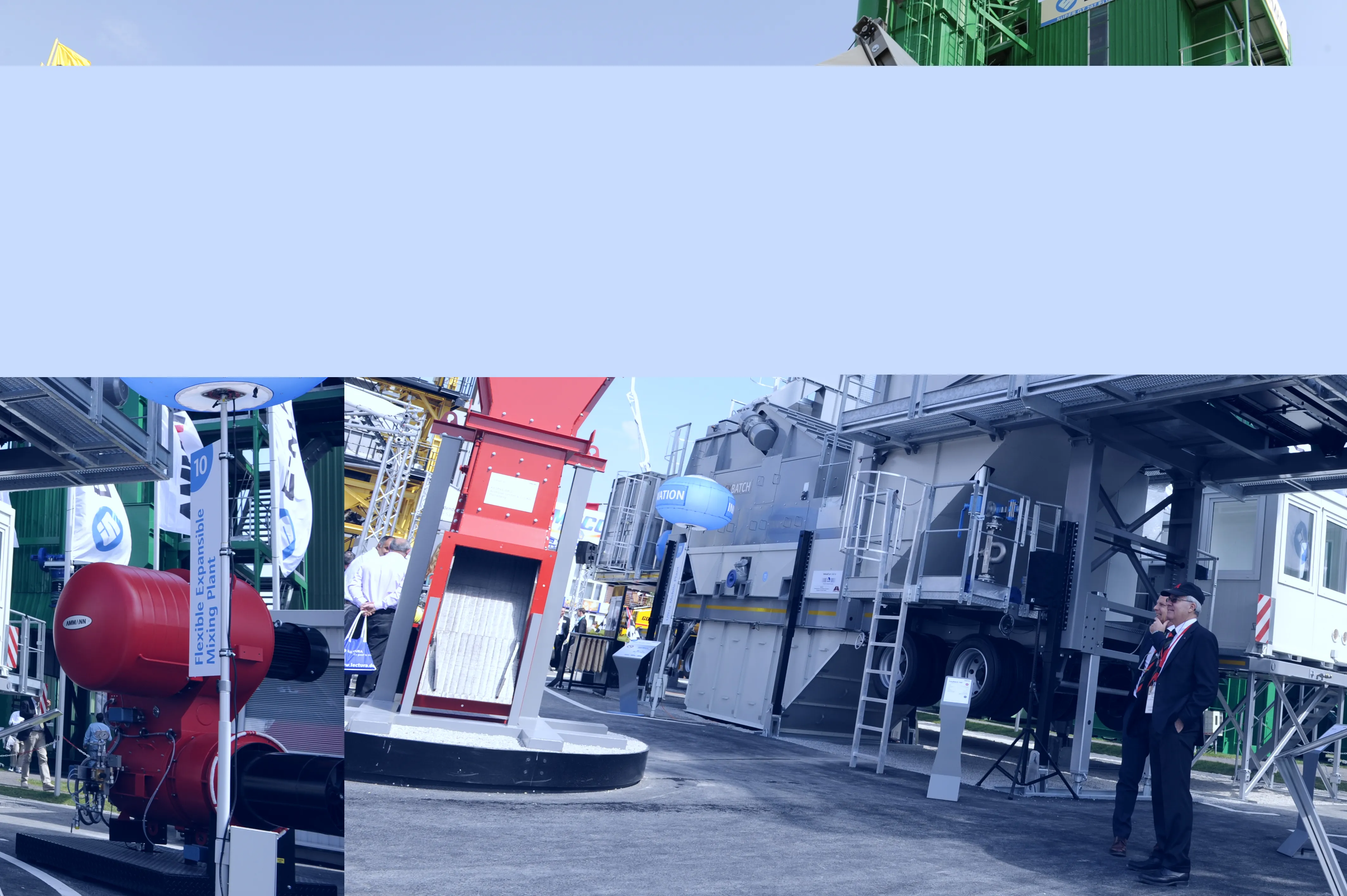

Asphalt Drum Mixers (ADM) says its SPL hot-mix asphalt plants are an affordable option for contractors with low production requirements. The SPL series is said to include all necessary components for drum-mixing asphalt production, yet can fit on a single trailer frame. The plants provide high reliability while producing asphalt at a very low cost per ton.

June 14, 2012

Read time: 2 mins

The SPL series is said to include all necessary components for drum-mixing asphalt production, yet can fit on a single trailer frame. The plants provide high reliability while producing asphalt at a very low cost per ton.

Available in 55, 100 and 146tonne-per-hour production rates, ADM’s SPL plants come standard with a drying/mixing drum, wet wash, cold feed bin and surge system. With all models contractors have the option of either a portable or stationary configuration, as well as automated or manual operation.

Due to their compact design, ADM says its SPL plants allow cost-efficient shipping worldwide. Like all other ADM equipment, the SPL series is pre-wired and pre-tested at the factory, reducing potential installation problems. Once running, the plants are said to operate with high efficiency, so fuel costs are kept low.

Only one plant operator and one loader operator are needed to run each of the SPL series. When servicing needs arise, downtime is said by ADM to be kept to a minimum because many repairs can be performed by on-site personnel. Maintenance costs are also said to be kept low, due to the use of inexpensive and easy-to-find parts and components.

Options include multiple silos and surge systems, baghouses, add-on cold feeds, scalping screens, control systems and asphalt cement tanks. In addition to the SPL, ADM offers the MileMaker Series (146 to 386tonnes per hour) and RoadBuilder Series (100 to 318tonnes per hour). Each plant can be custom designed to meet the requirements of individual sites.