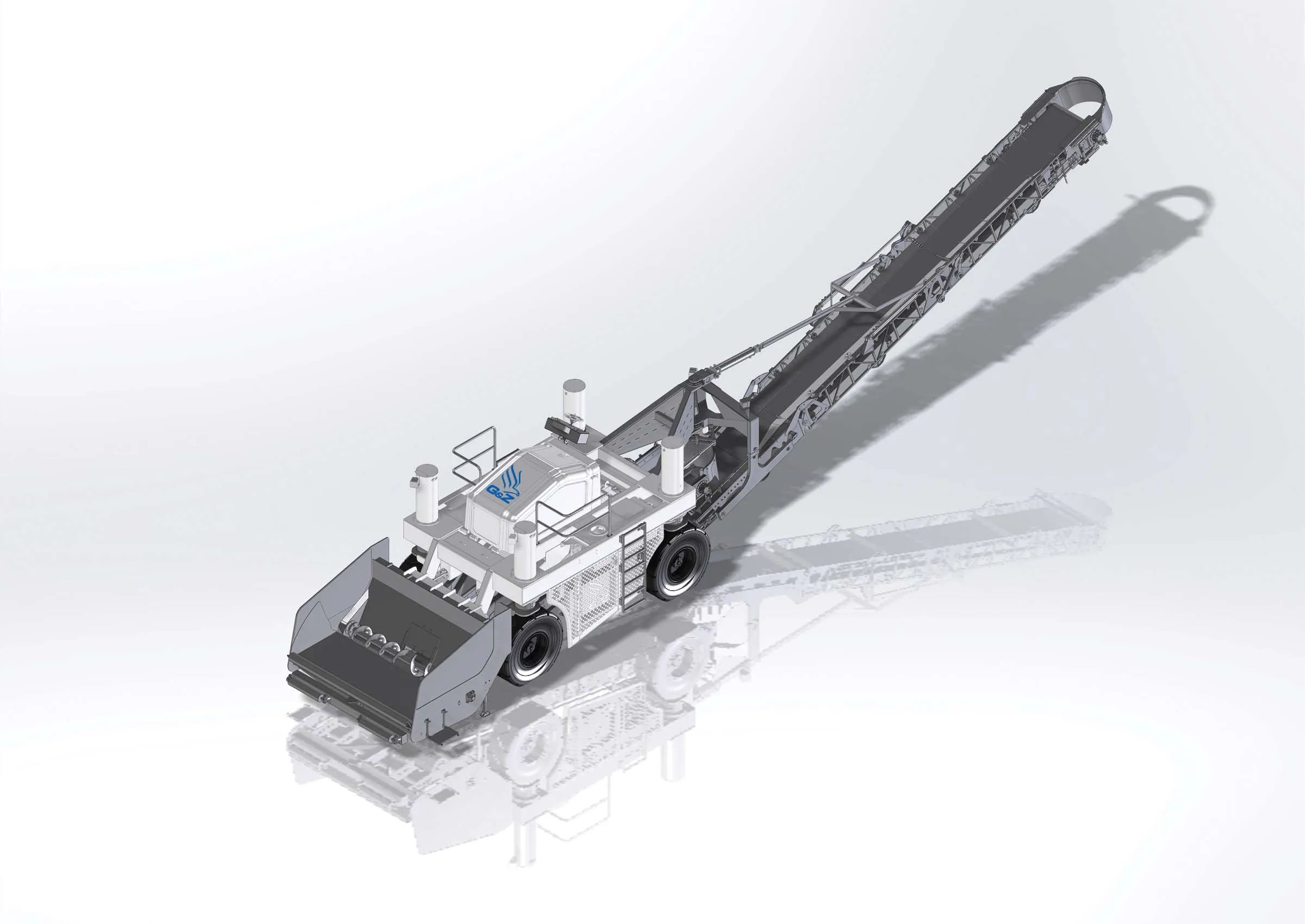

Gomaco has just added an optional hydraulically-folding rear conveyor belt to its versatile 9500 material handling machine. The company says the new feature on the machine, which can take on work as a trimmer, concrete and asphalt placer, and a shoulder trimmer, makes it easier to transport. It allows the conveyor to remain attached to the 9500 during shipping. The 9500’s shipping length with the new folding rear conveyor is just 12.7metres. Shipping height is 3.5metres. The new conveyor belt is said by Gom

May 9, 2012

Read time: 2 mins

The new conveyor belt is said by Gomaco to be the direct result of a contractor approaching the firm with a specific request. As part of the conveyor frame redesign process, Gomaco engineers are said to have rebuilt the 9500’s conveyor to be stronger and more rigid with a truss-style framework. The switch to control the hydraulically-folding rear conveyor can be placed at different locations on the back of the machine, which Gomaco says provides excellent operator visibility and safe operation.

The belt width is still 90cms and the rear conveyor maintains its 160° swing with hydraulic height adjustment up to 3.7metres. It has a 10.6metre long reach during machine operation, with a conveyor belt speed of 153metres per minute allowing fast placing of concrete or removal of trimmed material.

Gomaco says the twotrack 9500 with front-mounted trimmerhead allows trimming to the end of each pass or within centimetres of front obstacles. The powerful single-drive, hydrostatic motor is also said to offer superior production.

The 9500 has trimmer load control which controls the travel Material benefit speed for optimum power to the trimmerhead. Gomaco says the steady, easily controlled travel speed guarantees accurate trimming and jobsite mobility. It can make a 360 degree turn within its own length. The 9500 features a remote control handset, emergency stop buttons located on strategic areas of the machine, a back-up alarm, an alarm for conveyor swing, and a rotating beacon on the rear conveyor.