German asphalt and concrete plant manufacturer Lintec has launched a new containerised asphalt mixing plant.

February 6, 2012

Read time: 1 min

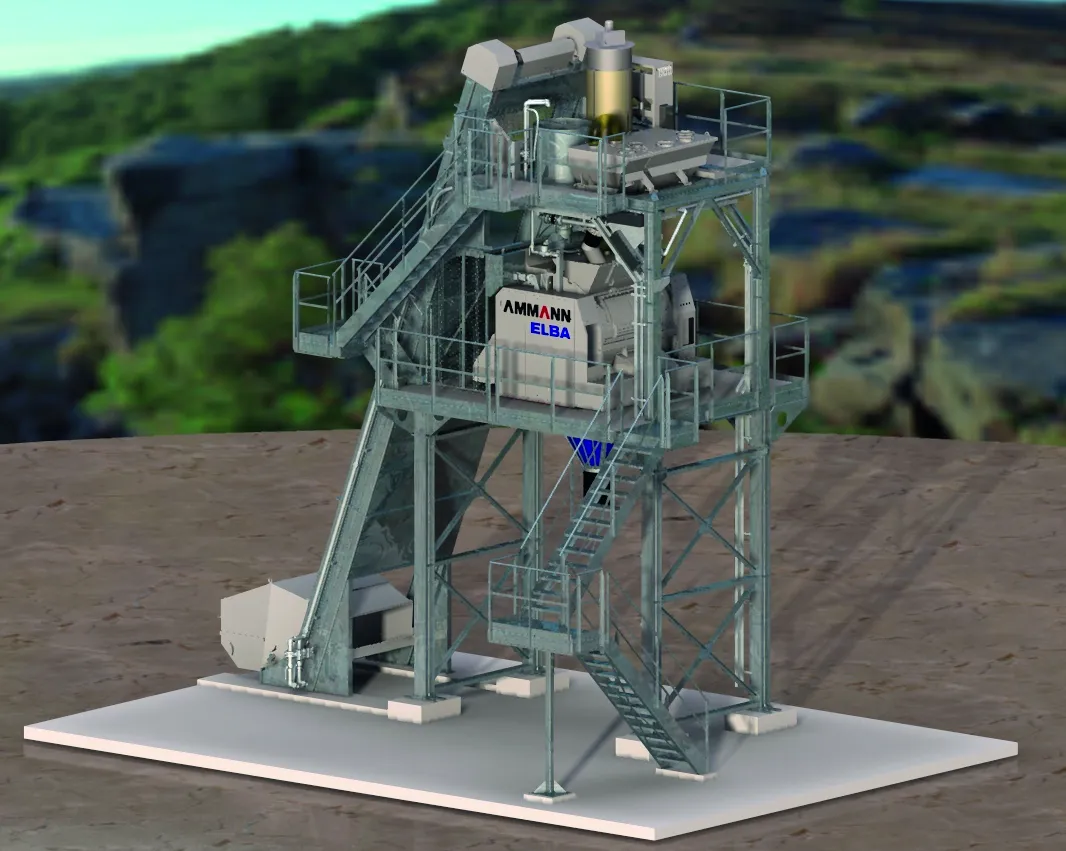

German asphalt and concrete plant manufacturer 1177 Lintec has launched a new containerised asphalt mixing plant.

The company, which recently invested some e10 million in a new factory in Jasien, Poland, produces its asphalt and concrete mixing plants in 100% ISO sea container dimensions, made up of easy transport units with all plant components (for example the mixer, burner for asphalt plants and electrical cabinets) already pre-installed into the containers when they leave the factory.

At Bauma, Lintec introduced the CSD 1200 asphalt plant (its smallest), which has a production capacity of 80tonnes/hour for mobile and stationary use, and a batch size of 1,350kg, and which rounds up its asphalt mixing plant range.

The plant, which was sent directly to its next exhibition, AUTOSTRADA in Kielce, Poland, has four screen decks; a 15tonne hot stone bin and a 10tonne reclaimed filler silo.

Lintec claims its containerised mixing plants allow short erection and dismantling time; no concrete foundations are required; they are environment friendly and offer protection against rain and UV-light.

The company, which recently invested some e10 million in a new factory in Jasien, Poland, produces its asphalt and concrete mixing plants in 100% ISO sea container dimensions, made up of easy transport units with all plant components (for example the mixer, burner for asphalt plants and electrical cabinets) already pre-installed into the containers when they leave the factory.

At Bauma, Lintec introduced the CSD 1200 asphalt plant (its smallest), which has a production capacity of 80tonnes/hour for mobile and stationary use, and a batch size of 1,350kg, and which rounds up its asphalt mixing plant range.

The plant, which was sent directly to its next exhibition, AUTOSTRADA in Kielce, Poland, has four screen decks; a 15tonne hot stone bin and a 10tonne reclaimed filler silo.

Lintec claims its containerised mixing plants allow short erection and dismantling time; no concrete foundations are required; they are environment friendly and offer protection against rain and UV-light.