The package is available as a retrofit option while the firm also offers new trailers with the system installed. The firm says that two- and three-axle tipper trailers with volumes of 24m³ can now be provided with all the available wall and tipper body strength options and also as fully insulated asphalt tipper trailers.

The body of the new Kögel asphalt tipper trailer is equipped with an integrated five-point measuring system and a temperature display unit with printer. The display alternately shows the five different measuring points and the average temperatures. The insulation is based on a thermosetting, high-performance insulation material with special suitability in the high-temperature range of up to 200°C. The outside cover as well as the entire vehicle frame and the tipper body are protected against corrosion by nano-ceramic technology and KTL coating with subsequent UV varnishing. A heat-resistant polyurethane sliding roof is used as insulation towards the top. Earlier generation Kögel tipper trailers can be retrofitted as the full insulation can be fitted at the firm’s plant and adds only 350kg in weight.

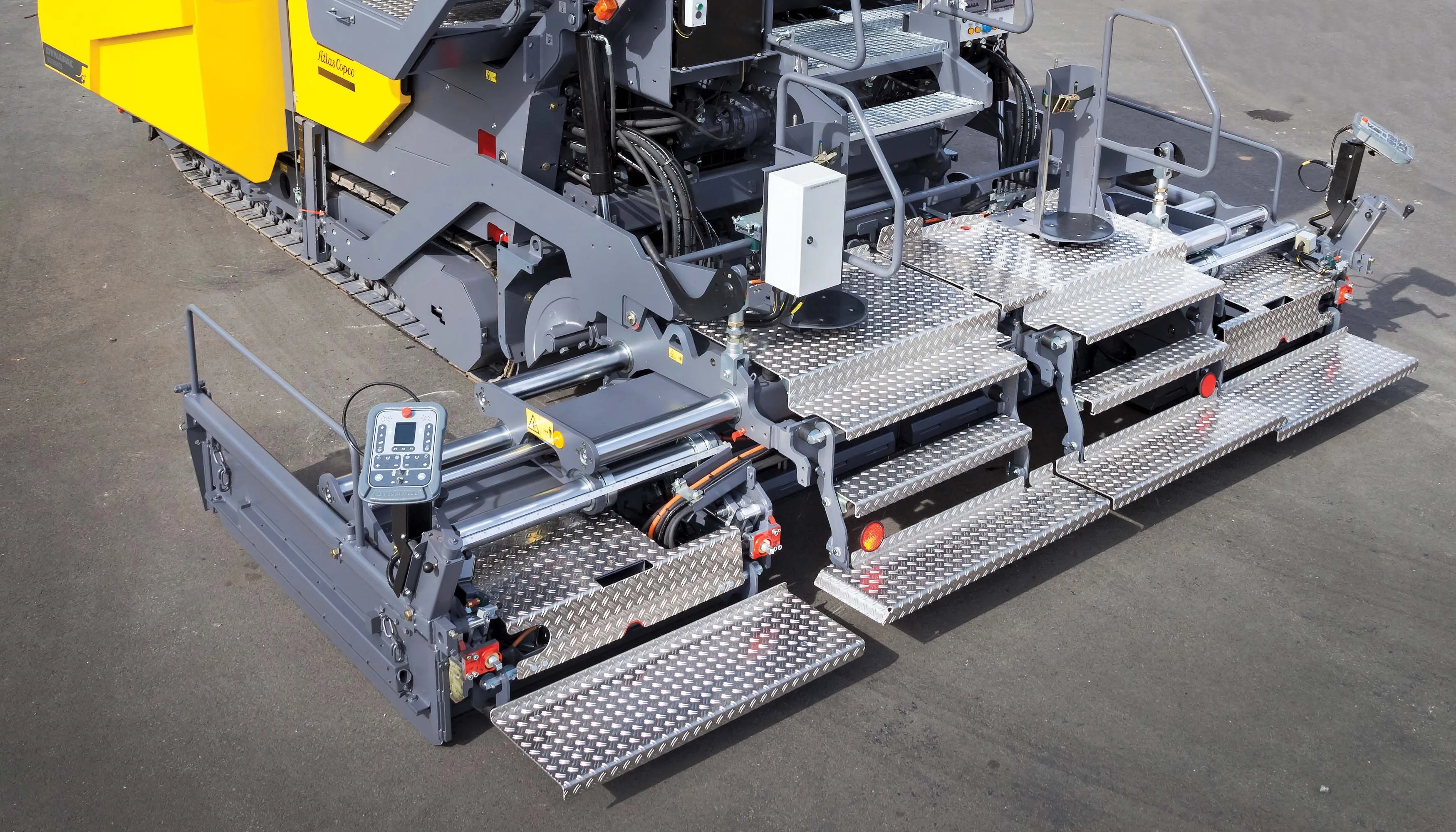

The new asphalt tipper trailers already have a 170mm body overhang which suits the units to road paving applications, so there is no need for a chute to be added. In addition, the redesigned locking device for the hinged underride guard also suits road paving applications.