The new model retains the advantages of the original track-mounted design but is also said to offer lower running and maintenance costs. The machine is designed to operate either separately or as part of a crushing and screening chain. The firm claims that the design is compact for its output and performance, further boosting its mobility. It has a low transport weight and the latest jaw crusher measuring 1000x600mm. The machine offers a capacity of up to 300tonnes/hour and benefits from hydraulically adjustable gap widths of 45–170mm. The gap can be adjusted at any time and the machine also has the firm’s patented non-stop system with overload protection and novel wear monitoring. Durable and robust, the

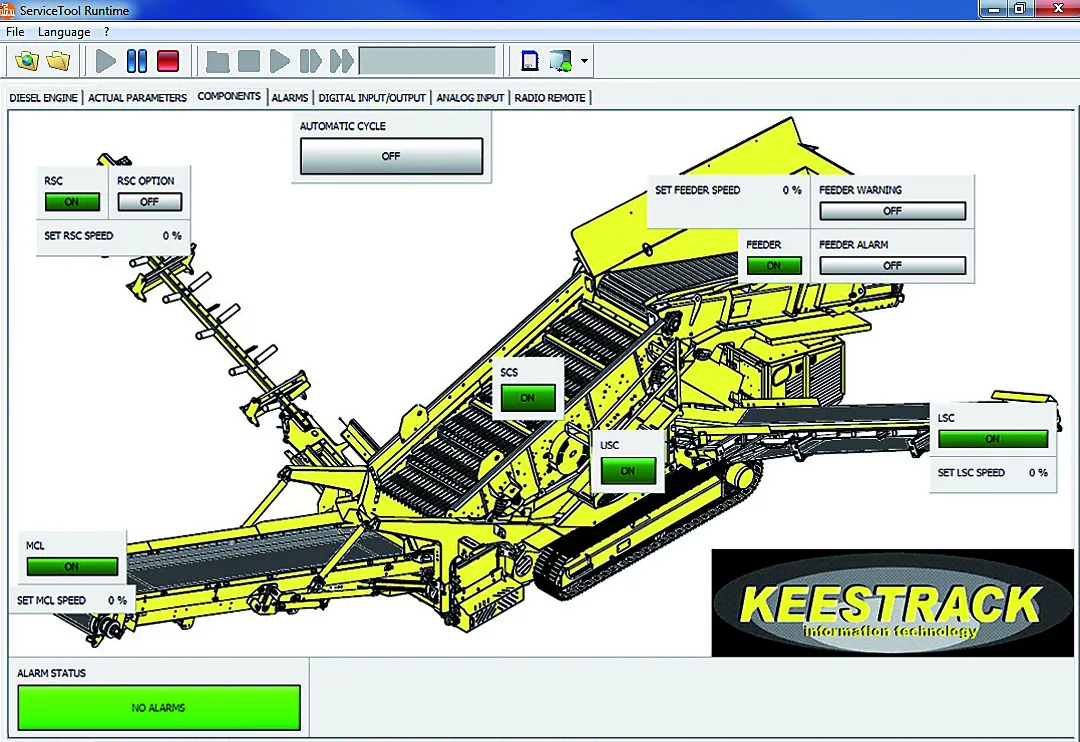

The diesel-electric Keestrack B3e has a proven crusher, heavy-duty vibrating primary screen and efficient track drive. Diesel-hydraulically driven, the machine has Keestrack’s load-sensing hydraulics for low fuel consumption from its 160kW

Meanwhile for higher performance demands or operators with access to onsite electrical power, Keestrack is offering its new B4e fully hybrid jaw crusher, which weighs 49tonnes. It has a 110kW electric motor driving the 1100x700 mm crusher as well as a 55kW motor/pump unit powering all the hydraulic components. The Keestrack B4e can also be operated from athe mains supply, which can achieve savings in energy costs of up to 70%. In mobile applications in the field, the onboard combination of 242kW diesel engine and 225 kVA generator powers the machine.