Modified bitumen can become unstable when it is stored inside a tank because the polymer rises to the top, meaning that the rheological behaviour of the bitumen varies through the tank. Cross-linking agents modify bitumen through a chemical action that stabilises the bitumen inside the tank to create a homogenous PMB and, hence, a homogeneous asphalt concrete.

Iterchimica produces two cross-linking agents: ITERFORT PH20, a solid which is added to the pre-blend tank at between 0.15-0.25% of the bitumen weight and ITERFORT PH17, a liquid which is poured into the tank at between 0.4-0.6% of the bitumen weight.

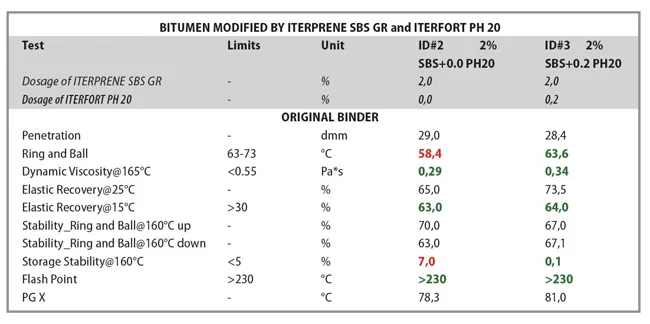

Tests for a customer in Uganda demonstrate the impact that cross-linking agents can have. Researchers compared bitumen modified with ITERPRENE SBS-GR at 2%, with and without ITERFORT PH20 at 0.2%. Results showed that the softening point increased from 58.4°C to 63.6°C, the viscosity at 165°C increased from 0.29 Pa*s to 0.46 Pa*s and the elastic recovery at 25°C increased from 63% to 65%.

Stability is verified using a test called the cigar tube test (from EN 13399) which is based on the softening point parameter. The PMB is put into a cigar-type tube which is stored in the oven for three days at 170°C. Samples from the top and bottom of the cigar are compared and the PMB is considered stable when the difference between the softening point of the samples is lower than 5°C.

In the Ugandan example, the difference between the softening point at the top and the bottom was 7°C without a cross-linking agent and 0.3°C with the cross-linking agent.

The right type of polymer is usually chosen by analysing the chemical composition of bitumen according to the ASTM D4124-09 specification and depends on its SARA (saturate, aromatic, resin and asphaltene) index. But the final performance of the PMBs are also connected with the phase inversion – that is whether the polymer and bitumen have become one material with the combined properties of the two original ones.

Cross-linking agents can increase the quality and stability of the phase inversion. Considering the many differences of the bitumen coming from various places, it is important to carry out the stability test for every different source of bitumen, said Iterchimica.