Asphalt plant specialist E-Mak has developed and patented a hot recycling system that saves energy while ensuring bitumen is not damaged during the material recycling process. Cleverly, its new plant re-uses heat generated by the burner and flows it through the tower to improve heat regeneration to maintain product quality.

Careful development of flights inside the tower increase the time it takes for material to descend, which also provides additional mixing capability while boosting heat absorption. E

August 21, 2013

Read time: 1 min

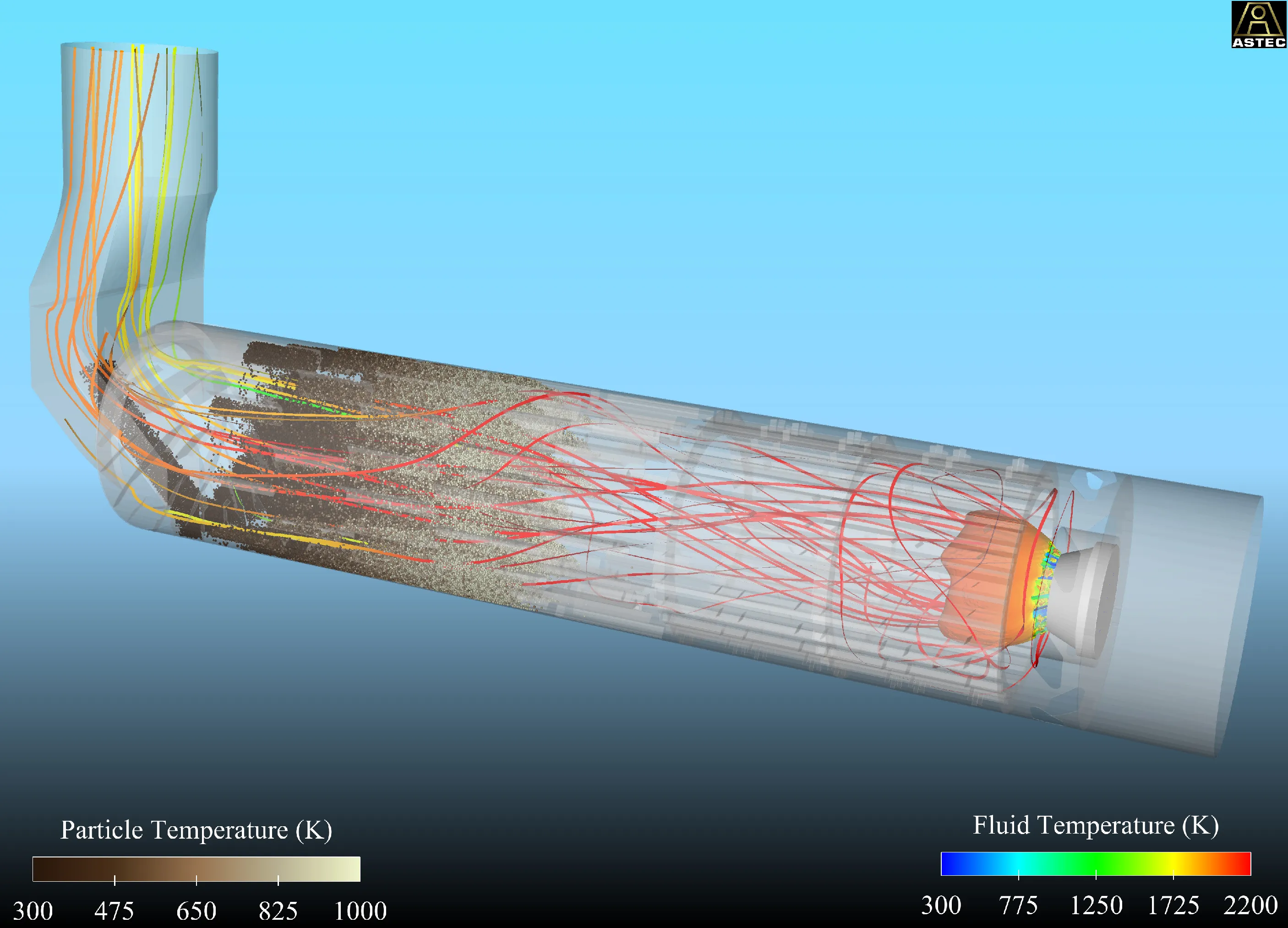

Asphalt plant specialist 208 E-MAK has developed and patented a hot recycling system that saves energy while ensuring bitumen is not damaged during the material recycling process. Cleverly, its new plant re-uses heat generated by the burner and flows it through the tower to improve heat regeneration to maintain product quality.

Careful development of flights inside the tower increase the time it takes for material to descend, which also provides additional mixing capability while boosting heat absorption. E-Mak is confident that its high efficiency plant design will boost asphalt recycling efficiency - output potential is up to 80tonnes/hour while using 35-40% RAP.

Careful development of flights inside the tower increase the time it takes for material to descend, which also provides additional mixing capability while boosting heat absorption. E-Mak is confident that its high efficiency plant design will boost asphalt recycling efficiency - output potential is up to 80tonnes/hour while using 35-40% RAP.