Biorefiner

“What it essentially does is mobilise the chemical matrix of these aged binders,” said Arizona Chemical’s business unit director for roads and construction Raquel Silverberg. “It restores the properties of the aged binder in RAP so that it behaves like new.”

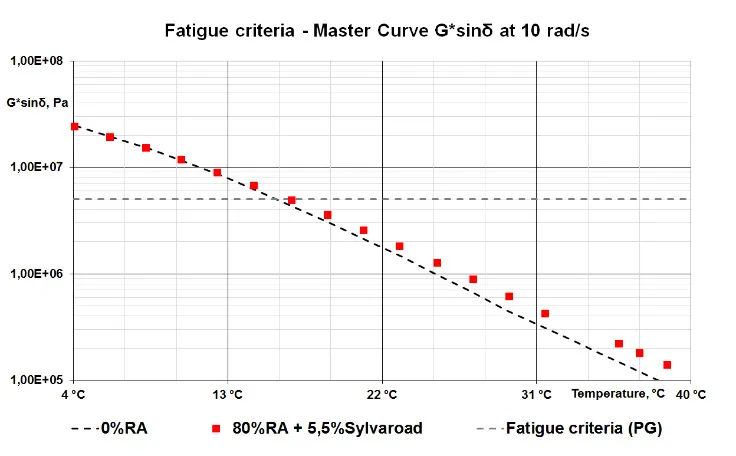

Where typically contractors are using 20 to 25% RAP, Sylvaroad RP1000 allows 40%, 50% or higher to be used, according to Silverberg. “This offers a step change in performance in terms of the recycled content you can use, while producing a high-performing road,” she said.

Arizona Chemical launched the product in October 2013. To date it has been used in the US and several European countries on municipal roads, parking lots, industrial roads and in parking applications. Silverberg says that it will soon be tested on public highways in the US.

Arizona Chemical decided to develop Sylvaroad RP1000, its first product developed specifically for paving applications, having carried out an extensive study into market needs. Those it identified were to consume less virgin material, to reduce cracking and to increase the flexibility of pavement mixes.

“We are chemists by nature, not pavement designers but we asked questions, and put our finest scientists on the job,” said Silverberg. “We found some of the world’s experts on bitumen science so we could understand what actually happens to an aged binder that’s found in RAP. Until you can see and measure the problem, you cannot solve the problem.”

Produced from 90% refined biorenewable materials, Sylvaroad RP1000 is a derivative of tall oil which comes from pine trees. Less than 1% dosage is required to restore an aged binder’s properties according to Arizona Chemical, it is fully miscible, thermally stable and has a higher flash point than bitumen.

Though some biomaterials can be inconsistent, this product has been designed specifically for its application which means its performance will not vary, says Silverberg.

Sylvaroad RP1000’s sustainability credentials are an added bonus to most contractors or asphalt producers, said Silververg. “The greenness of a product is quite often secondary to performance. Superior performance is why someone would buy your product. When you combine that with the biorenewable element, then you have a pretty compelling value proposition."