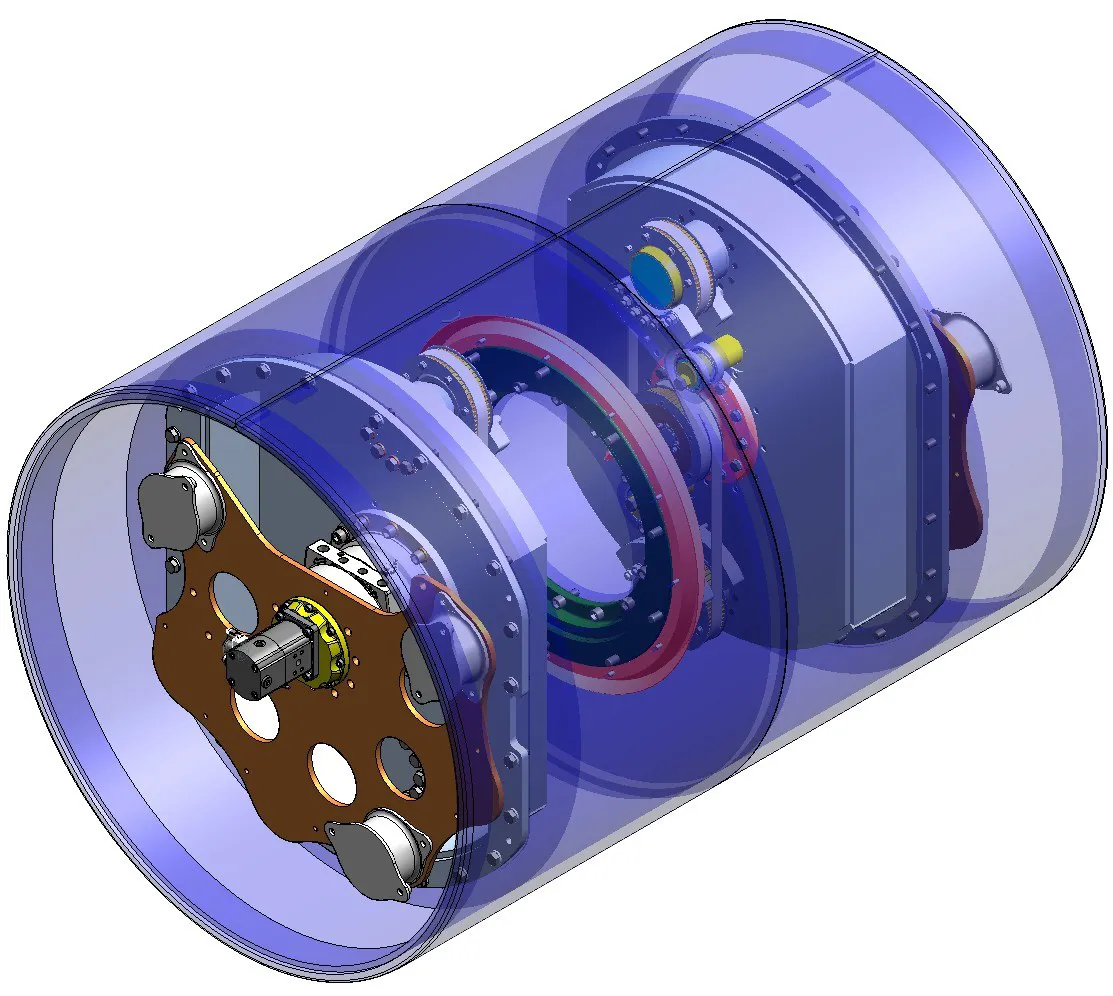

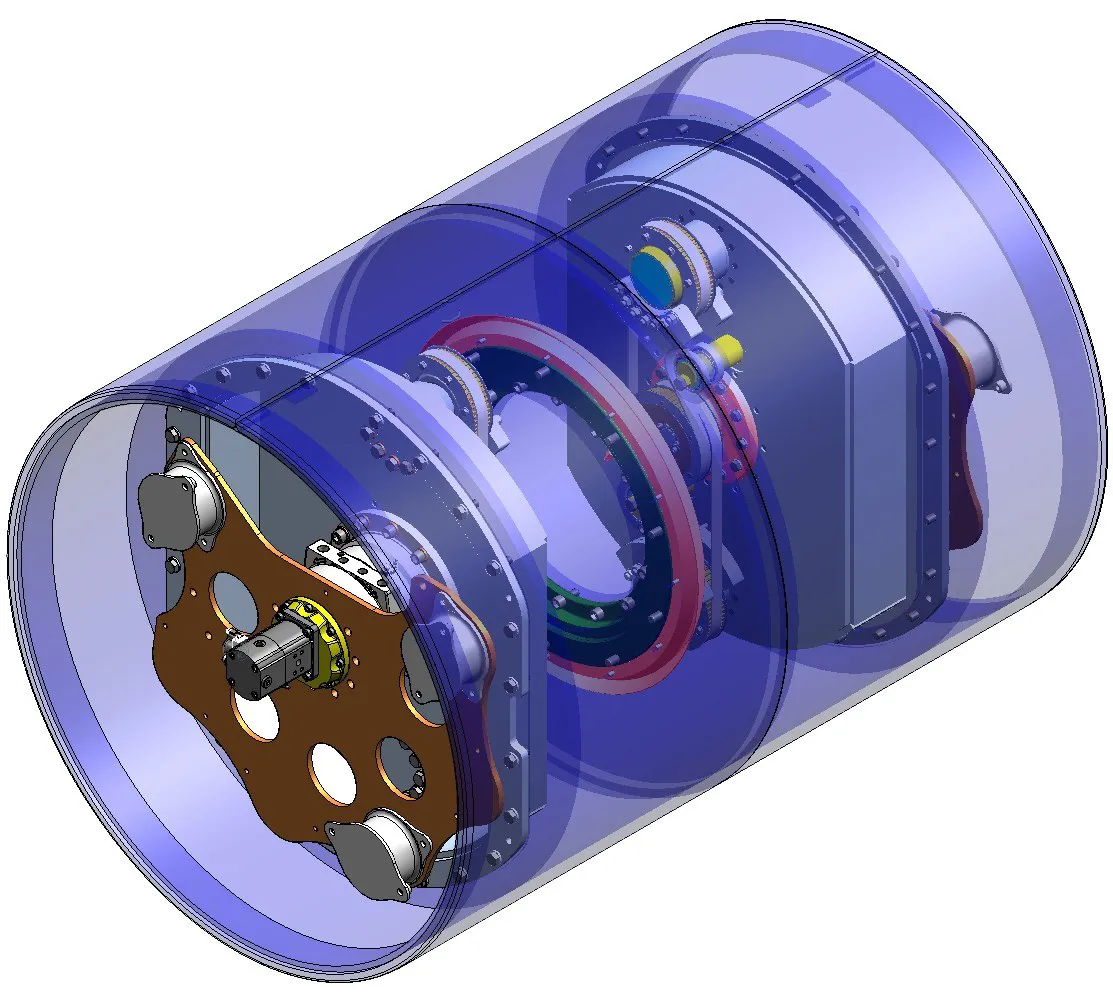

Nurock Mixers has developed an innovative compact volumetric machine.

April 4, 2012

Read time: 1 min

By replacing the chains, sprockets and mechanical components with hydraulics, the unit delivers a higher production rate as well as lower running costs and shorter downtime.

An optional onboard computer holds up to 50 preset mix designs. Highly versatile, the NUVM 1.5 is available in three versions, as a static unit for precast applications, as a trailer-mounted model for on-site use and mounted on a 7.5tonne truck for use in urban areas.