After six months of operation, the company has a positive view of this addition to its production capacity.

The firm was considering an expansion of production capacities at the plant in Lviv, a convenient location for transportation in the heavily urbanised region of Western Ukraine where construction activity is intense. The firm opted to buy the unit from

The installation in Lviv was completed quickly, despite poor weather conditions with snow and icy winds. The plant is designed to withstand winter conditions, while the cladding for the CBT was provided by the plant owner.

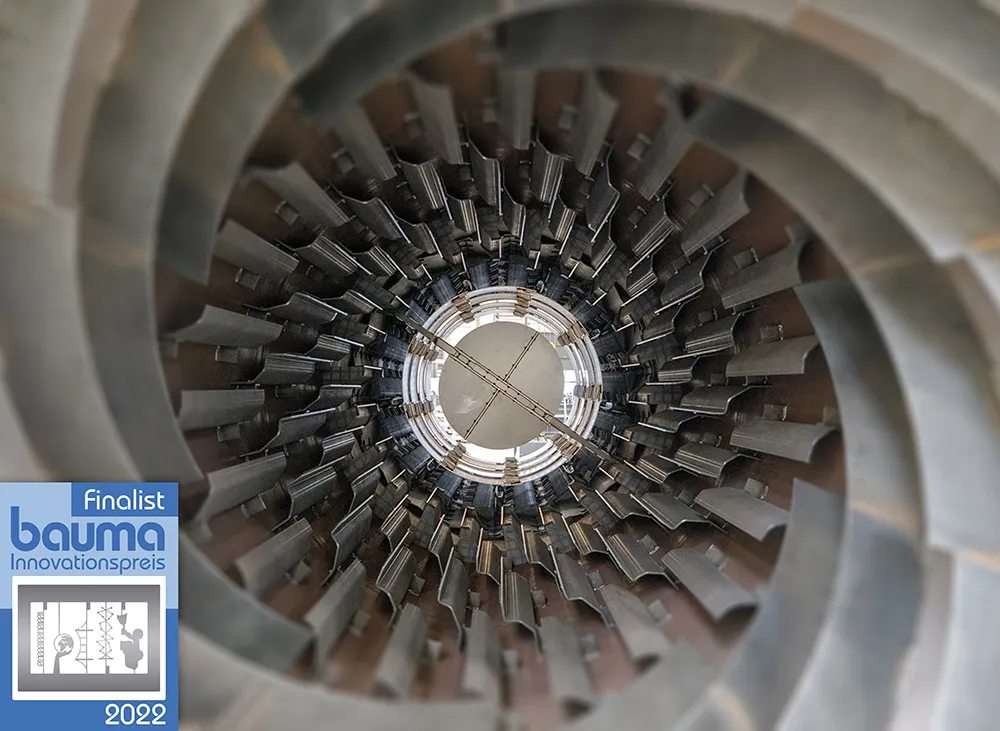

The machine’s as1 Plant Control System is said to be simple and self-explanatory. Together with the control cabinet, it is well protected inside the integrated control container but is also easily accessible. A modern safety system with key transfer ensures that employees are safe while operation is in progress.

The Betonbud team soon found that they were reaping positive rewards from the Ammann CBT Elba's impressive performance. The new acquisition is particularly convincing when compared to the older plant. With a 1m³ single-shaft mixer, the CBT 60 SL Elba achieves a higher hourly output than the existing plant with its 1.5m³ pan mixer. Total output of 60m³/h enables Betonbud to meet market demand and supply numerous different varieties of concrete with consistently excellent quality, depending on the aggregate.