However new screening media from

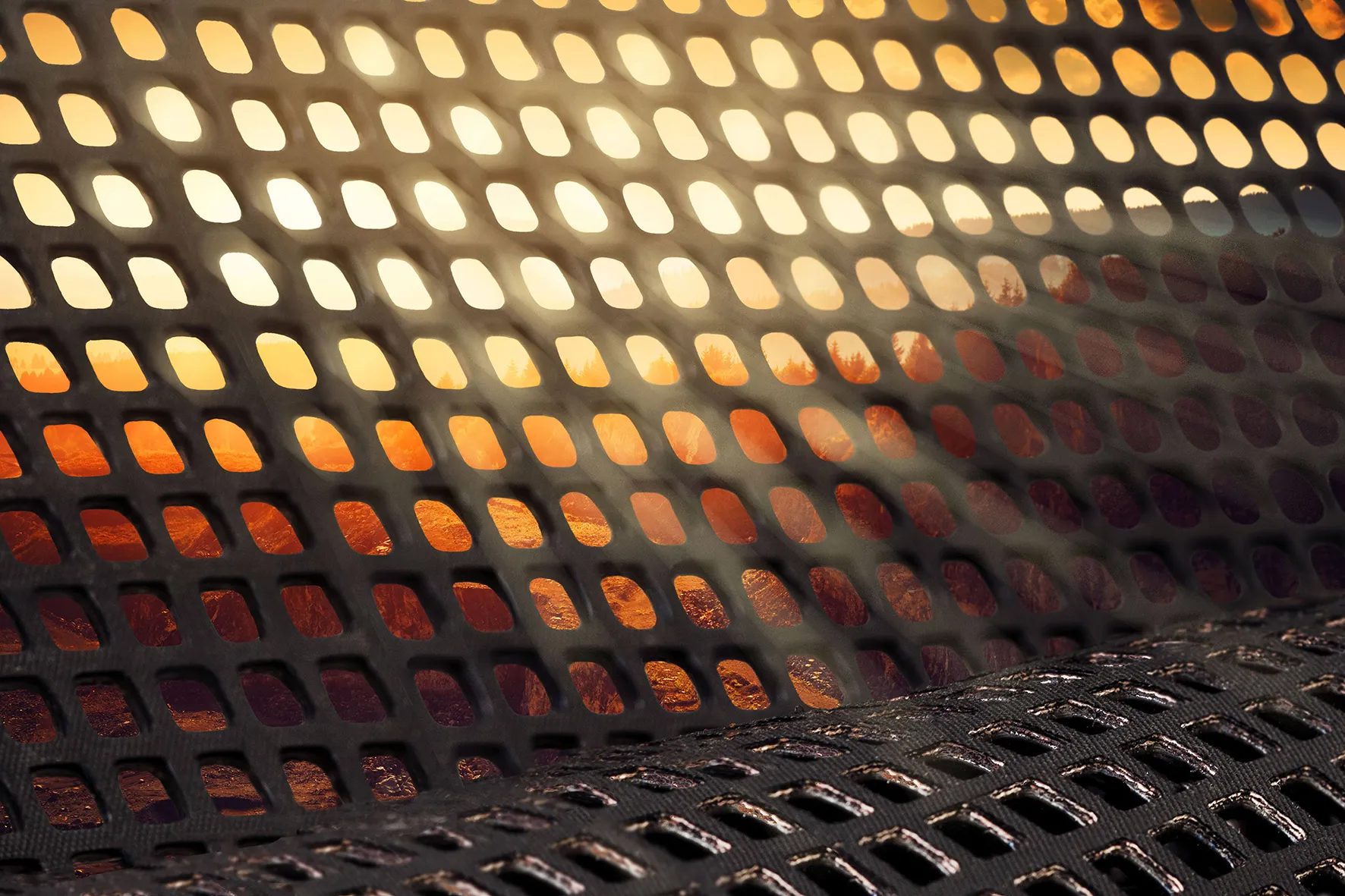

This newer generation WR Modular screening media offers greater wear life as well as accurate screening and versatility of operation.

The operation quarries a gneiss deposit which has increasingly proved to be popular with concrete producers due to the gneiss, unlike granite, emitting no radon.

Although the quarry has been able to operate highly efficiently, an increasing problem was found with regards to the screening media used. Due to the hard wearing nature of the gneiss, and the constant demands for accurate production, conventional steel wire mesh screens needed to be replaced frequently incurring costs for the new equipment and also for machine downtime.

The quarry operators contacted Sandvik for a solution and the firm suggested that the existing screen meshes be replaced with the WR modular screening media.

This system features an open production area greater than is found in conventional modular media. This is achieved through the use of cross-mounted flexible screen panels that generate a wave like cascade effect in the material bed. The design improves stratification, allowing undersize material to find a more rapid path to the screening surface. Additionally the system optimises screening accuracy as the modular screening media utilises a fibre reinforced rubber screen membrane, which enables the use of thinner panels, with closer aperture spacing, maximising the open screening area.

The initial installation of the WR screening media at the Skanska Hällevadsholm quarry took two days, replacing the previous screen with the modular media on the existing VFS42/18-2 screen. Due to the success of the WR media Skanska Hällevadsholm has further adjusted the production flow as the system is easy to use, and versatile. Hence the quarry now also uses the WR media for washing 16-22mm aggregate to be used in asphalt, with 1,500-1,600tonnes of crushed rock now passing through the screen on a daily basis.