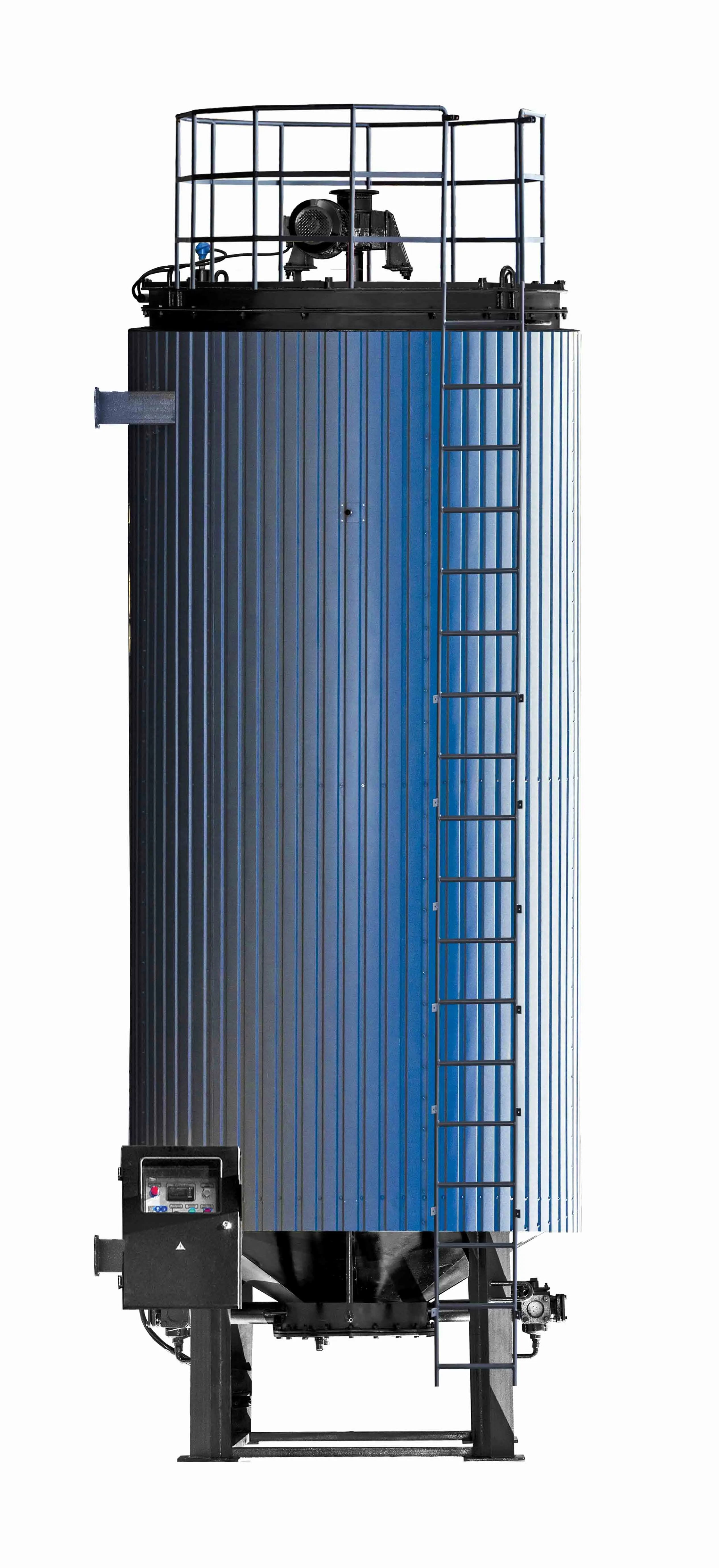

Improved bitumen storage is claimed for the new SBM-15 tank from GlobeCore. The firm has upgraded its existing design of modified bitumen storage tank to increase capacity, efficiency and versatility. A key feature is the new structural design with its downwards cone-shaped bottom. This is said to solve the problem of heat loss in the lower part of the tank while a minimum 200mm of heat insulation ensures it is thermodynamically efficient.

The new model is 500mm shorter, allowing a customer to transport

October 27, 2016

Read time: 2 mins

RSSImproved bitumen storage is claimed for the new SBM-15 tank from 8521 GlobeCore. The firm has upgraded its existing design of modified bitumen storage tank to increase capacity, efficiency and versatility. A key feature is the new structural design with its downwards cone-shaped bottom. This is said to solve the problem of heat loss in the lower part of the tank while a minimum 200mm of heat insulation ensures it is thermodynamically efficient.

The new model is 500mm shorter, allowing a customer to transport two storage tanks on a single 20tonne semi-trailer. However the operational capacity of modified bitumen storage tank SBM-15 has been increased from 15-15.5m3.

Meanwhile the roof shape does not allow rain to accumulate. For safe operation it can be covered with corrugated sheet and fitted with a ledge around the perimeter. The inspection manhole has a bigger opening and is equipped with non-removable grill.

For measuring the height of bitumen level in the tank the firm has fitted a membrane pressure sensor. The block is mounted at the bottom of the tank and sensor readings are shown on the control panel. To control the temperature of bitumen there are two shell cases with temperature sensors located at different depth in a tank.

The control cabinet has two doors and a control panel installed on the inside door. The external door prevents dust and water reaching the control panel and has an inspection window that allows the user to monitor sensor readings without opening control cabinet.

The new design also includes an emergency overflow pipeline preventing spillage of hot bitumen in emergency situations. This inlet can also be used for additional bitumen circulation. To prevent outside plating from buckling while mounting a tank for use, a lower support is added with a cylinder fixing pole that can be used for support.

The new model is 500mm shorter, allowing a customer to transport two storage tanks on a single 20tonne semi-trailer. However the operational capacity of modified bitumen storage tank SBM-15 has been increased from 15-15.5m3.

Meanwhile the roof shape does not allow rain to accumulate. For safe operation it can be covered with corrugated sheet and fitted with a ledge around the perimeter. The inspection manhole has a bigger opening and is equipped with non-removable grill.

For measuring the height of bitumen level in the tank the firm has fitted a membrane pressure sensor. The block is mounted at the bottom of the tank and sensor readings are shown on the control panel. To control the temperature of bitumen there are two shell cases with temperature sensors located at different depth in a tank.

The control cabinet has two doors and a control panel installed on the inside door. The external door prevents dust and water reaching the control panel and has an inspection window that allows the user to monitor sensor readings without opening control cabinet.

The new design also includes an emergency overflow pipeline preventing spillage of hot bitumen in emergency situations. This inlet can also be used for additional bitumen circulation. To prevent outside plating from buckling while mounting a tank for use, a lower support is added with a cylinder fixing pole that can be used for support.