Asphalt Burner Services Ltd have installed another V16 Vulcan burner, at Eurovia Ipswich plant. Aiming to improve their current overall efficiency and boost performance on running the Lintec asphalt plant.

April 16, 2015

Read time: 1 min

Asphalt Burner Services Ltd have installed another V16 Vulcan burner, at Eurovia Ipswich plant. Aiming to improve their current overall efficiency and boost performance on running the Lintec asphalt plant.

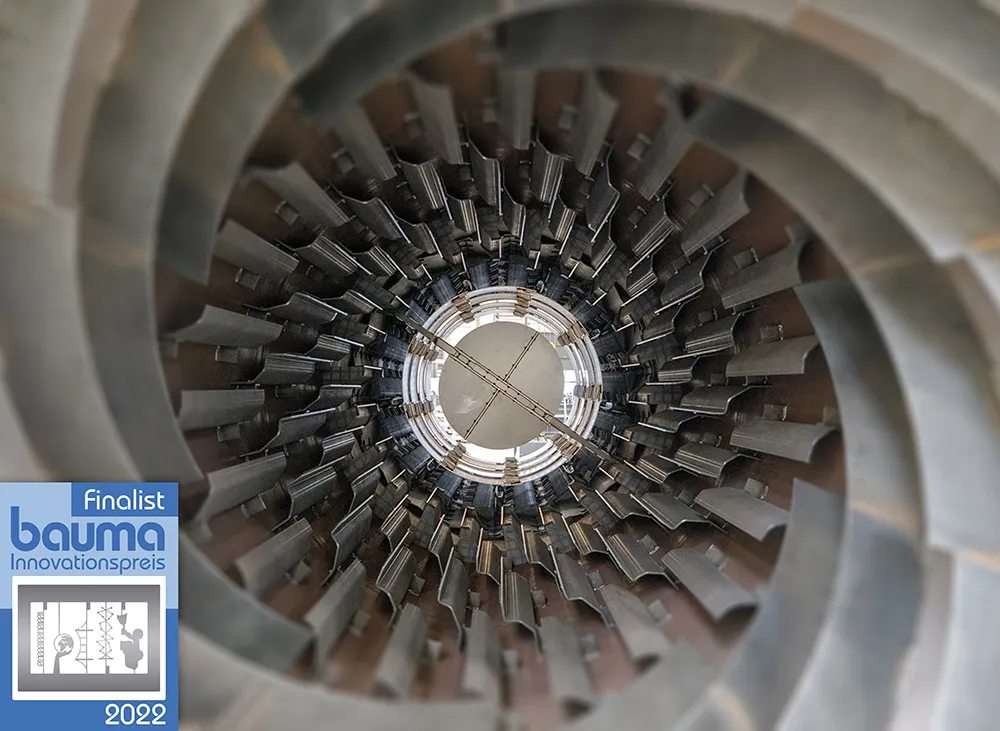

The Vulcan V16 Burner is designed to operate on two types of fuel oil; both fuels are fully optimized for efficient performance.

The 16000kw, low pressure Vulcan burner has been installed on to a new 1.6mtr Lintec dryer with the capability of 160tph. The addition of the Vulcan Burner combined with the high specification Lintec drying system will enhance Eurovia's existing asphalt production at their Ipswich site.

The new Vulcan Burner range is simply an added bonus feature for the company.