Accurate technology has been utilised to measure the loads carried by dump trucks on a project in Russia

Specialist supplier LASE commissioned the LaseTVM tool on a road construction site for contractor EuroTransStroy at a construction site in St Petersburg, Russia. The laser-based measurement system is able to determine the volume of bulk materials such as sand and crushed stones with high accuracy. This can be used to prevent differences in loads from one truck to another, so as to ensure consistency. The system also identifies truck license plates and the load area, providing comprehensive data collation.

EuroTransStroy is one of the biggest road construction companies in Russia and is involved in the road extension of the M11 highway from Moscow to Saint Petersburg, which should be finished for the beginning of the 2018 FIFA World Cup. The total length of this highway connection is around 684km, with work on the final 38km stretch benefiting from this technology. During the construction phase, large quantities of sand and crushed stones are being used for the base course of the asphalt by EuroTransStroy. To ensure that accurate and consistent quantities are used, the volume measurement system was required for use with the dump trucks. By applying the laser-based application LaseTVM - Truck Volume Measurement, the customer has been able to ensure that material deliveries are to the precise volumes required.

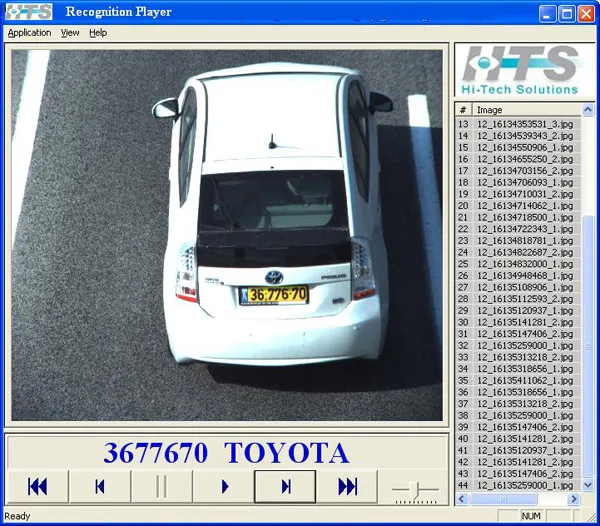

The system is installed at a stationary checkpoint next to the motorway where a 3D laser scanner from the LASE 3000D-C2-11x Series is mounted on a metal framed truck gate. The laser measurement data is delivered to the LaseTVM software and this provides the operator with the necessary data. Two further IP-cameras are installed to recognise the truck license plates. For the evaluation of the truck license plates, the Russian distribution partner from LASE, OOO Fest, has applied a special video analysis software called ScanMonitoring as a subsystem. An additional video camera on top of the gate monitors the trucks, showing the level and the type of material to the operator. A cover hood protects the 3D laser scanner and the cameras from the weather and an additional lightning device allows camera recognition by night.

The standard operating procedure starts with the entry of a loaded truck approaching the gate at a low speed, where the license ID, the time and a view of each incoming truck is recorded. Then the truck has to reach a central position under the gate where the laser scanner starts the 3D measurement process. At the same time the operator can check against the loaded material type within the delivery documents and the camera images. After a 10-second scan the measurement procedure is finished and the truck can drive to the storage yard for unloading.

Afterwards the truck needs to return to the measurement gate to check that it is empty. The 3D laser scanner measures the empty load area of the truck and forwards the scan data to the LaseTVM software, which calculates the volume from the difference between both measurement data.

EuroTransStroy is able to monitor all truck loads and material deliveries using the software. With this system the customer is protected against all possible weight or volume manipulations, such as faulty measurements from weight increases due to humidity. Or if the material is delivered with a volume 10-15% lower than stated in the purchase order, this will be identified. It means that the customer does not pay more for materials that have not been delivered.

Efficient truck loading to optimise operations

Specialist supplier LASE commissioned the LaseTVM tool on a road construction site for contractor EuroTransStroy at a construction site in St Petersburg, Russia. The laser-based measurement system is able to determine the volume of bulk materials such as sand and crushed stones with high accuracy. This can be used to prevent differences in loads from one truck to another, so as to ensure consistency. The system also identifies truck license plates and the load area, providing comprehensive data collation.

September 14, 2017

Read time: 3 mins