Ty-Max is poured using open cast technology and permanently hardens when cured to maintain its chemical properties, so it resists wear and tear. The polyurethane also wears exponentially longer than wire cloth and handles direct feed better, maximising productivity by reducing change-outs.

Additionally, Ty-Max features an internal wire grid as thick as 9.5mm to reinforce the screen – something not offered by modular polyurethane products.

Ty-Max also is designed to save on conversion and maintenance costs. Tensionable hooks come standard with Ty-Max screen sections. This eliminates the hassle of expensive deck conversions such as a switch from a woven wire cloth, which requires a cambered deck, to a polyurethane modular product.

However, Ty-Max is hooked for a cambered deck to eliminate the need for a deck conversion, making it ideal and cost-effective for both the aggregate and mining industries.

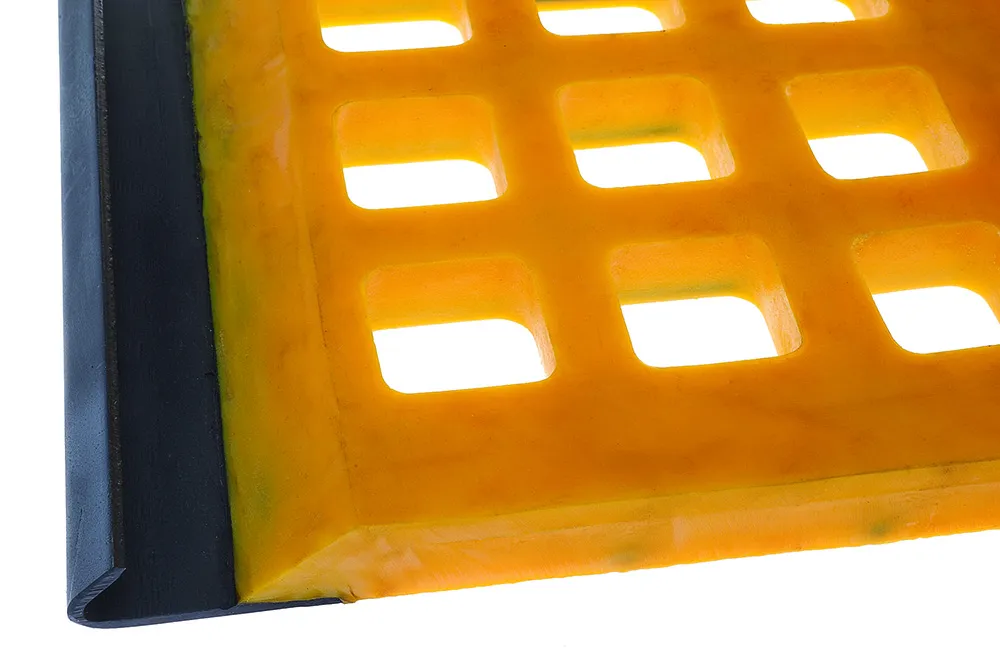

Ty-Max features square or slotted tapered openings to easily release near-sized material. The top of each opening is narrower than the bottom, helping prevent pegging, which means more profits through improved efficiency and less downtime.

Haver & Boecker offers several Ty-Max options to fit a variety of applications. Standard Ty-Max easily manages most operations where bar rail spacing is up to 304.8mm, while heavy-duty Ty-Max handles higher impact applications and deep bed depths on vibrating screens with bar rail spacing up to 406.4mm. The heavy-duty sections feature thicker wire reinforcements for withstanding large top sizes and heavy material. Finally, Dual Durometer Ty-Max features a top layer that is softer than the bottom to alleviate pegging. Also, the durable polyurethane easily absorbs the impact in wet or dry applications.

Optional features include high-temperature Ty-Max for applications requiring the screen to withstand high heat. There is also a specially formulated flex membrane that uses increased flexibility to force particles through openings, reducing blinding. Haver & Boecker also offers screen media with blank sections to increase wearability in impact areas.

Ty-Max openings range from 2.38-101.6mm. The screen media is compatible with any vibrating screen brand and can handle material top sizes up to 304.8mm, depending on particle type, drop height, rail spacing and feed method.