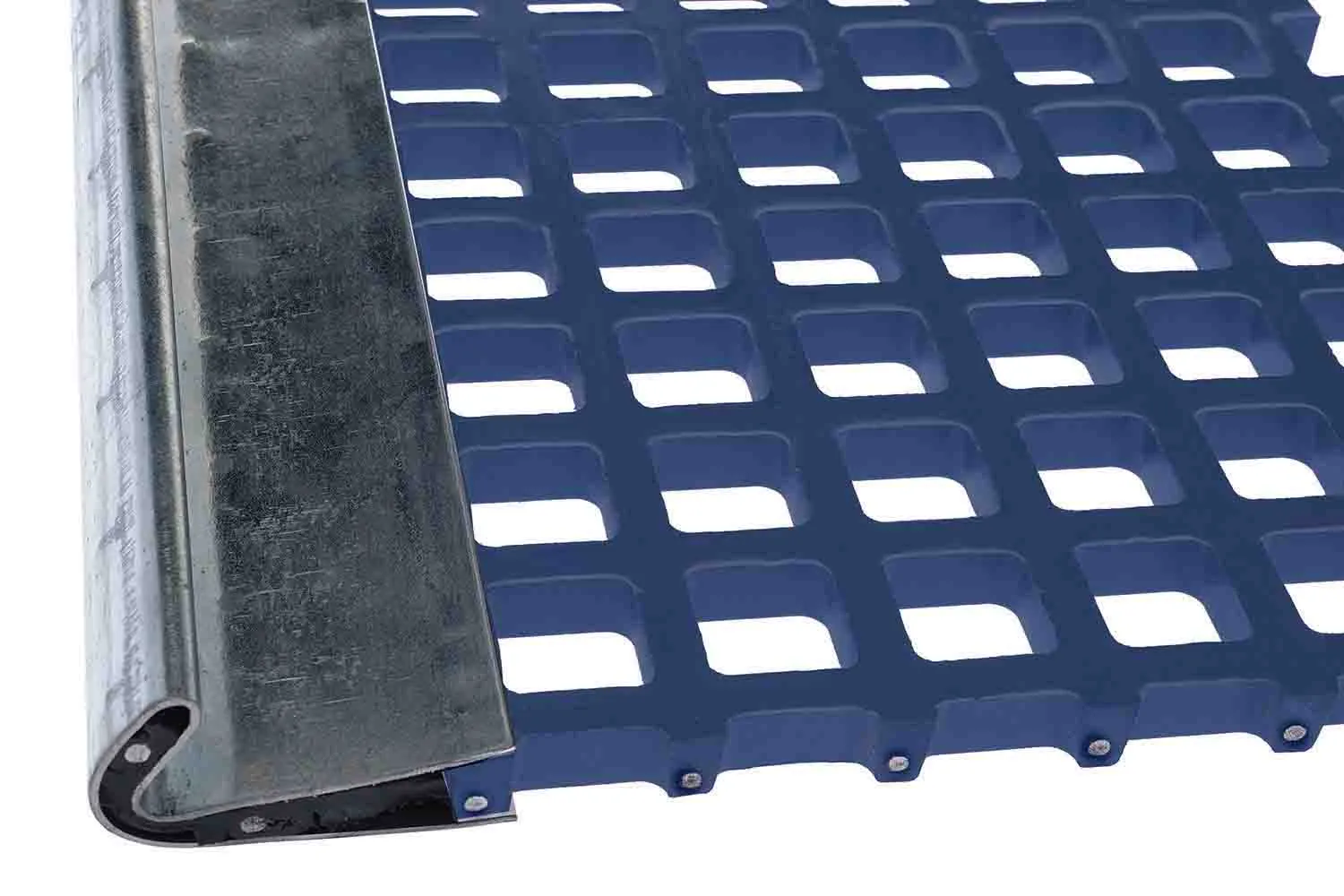

Materials washing specialists CDE Global has announced the introduction of several screens in the ProGrade range which it says are lighter but stronger and so require less power to operate. The bolted screens also include no welds and are galvanised as standard, all of which serves to maximise plant life, maximise plant availability and minimise maintenance time. The patent pending CDE U-Span cross members are modular in design and have increased space between screen decks, allowing for quick and easy acces

March 10, 2015

Read time: 1 min

Materials washing specialists 3168 CDE Global has announced the introduction of several screens in the ProGrade range which it says are lighter but stronger and so require less power to operate.

The bolted screens also include no welds and are galvanised as standard, all of which serves to maximise plant life, maximise plant availability and minimise maintenance time.

The patent pending CDE U-Span cross members are modular in design and have increased space between screen decks, allowing for quick and easy access to replace screen media.

The new screen design system is now available on the 2-deck ProGrade P2-75 and P2-108, as well as the 3-deck P3-75 and, in several months, the P3-108.

The bolted screens also include no welds and are galvanised as standard, all of which serves to maximise plant life, maximise plant availability and minimise maintenance time.

The patent pending CDE U-Span cross members are modular in design and have increased space between screen decks, allowing for quick and easy access to replace screen media.

The new screen design system is now available on the 2-deck ProGrade P2-75 and P2-108, as well as the 3-deck P3-75 and, in several months, the P3-108.