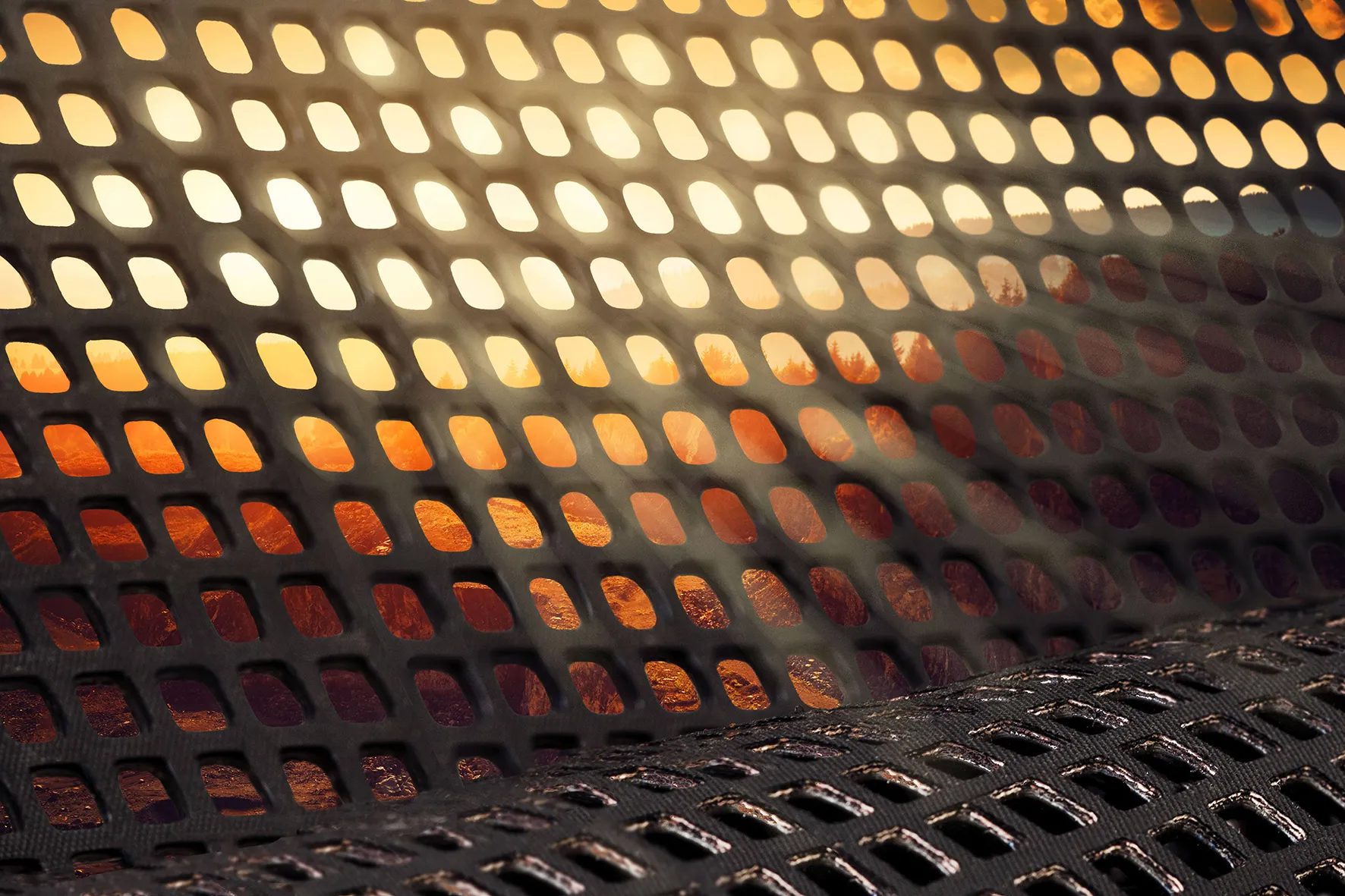

Major Wire Industries’ (MWI) Flex-Mat 3 Double-Wire High-Performance, Self-Cleaning Screen Media is said to increase production when screening high-impact, heavy and abrasive aggregate on top decks.

The side-by-side wire design of the Flex-Mat 3 Double-Wire is said by Canada-based MWI to add a slight spring to the wire that absorbs impact from heavy material or when the material is dropped from a longer distance. The new self-cleaning screen media system’s vibrating wire technology, combined with its side

July 18, 2012

Read time: 2 mins

The side-by-side wire design of the Flex-Mat 3 Double-Wire is said by Canada-based MWI to add a slight spring to the wire that absorbs impact from heavy material or when the material is dropped from a longer distance. The new self-cleaning screen media system’s vibrating wire technology, combined with its side-by-side wire design, is said to increase screen capacity and throughput while eliminating pegging on top decks. It is also said to stop the frequent ‘popcorn effect’ when single wire is used to screen high-impact and heavy materials.

With its two wires lying flat against each other, stopping crimps protruding upwards and interfering with material flow, the Flex Mat 3 Double-Wire’s flat screen surface is said by MWI to extend wear life up to three times when compared to traditional woven wire with high wear spots.

Flex-Mat 3 Double-Wire uses the same screen media technology as traditional Flex-Mat 3, which is said to provide up to 30% more screen capacity than woven wire, and up to 50% more screen capacity than polyurethane and rubber panels.

Distinctive lime-green polyurethane strips bond individual wires as they run from hook to hook and allow them to vibrate independently at different frequencies. This is said by MWI to eliminate blinding, pegging and clogging. In addition, the independently vibrating wire technology is said to increase product throughput by up to 40% over traditional woven wire and polyurethane or rubber panels.

Available in wire diameters up to 9.5mm and opening sizes up to 101.6mm the Flex-Mat 3 Double-Wire is made from OptimumWire, manufactured with high carbon and manganese content to create what MWI says is the industry’s best combination of ductility, hardness and tensile strength.

Also said to be less susceptible to breaking in high-impact conditions with highly abrasive materials, Flex-Mat 3 Double-Wire is being marketed as an ideal screening solution for markets such as aggregates, mining, and recycled concrete and asphalts.