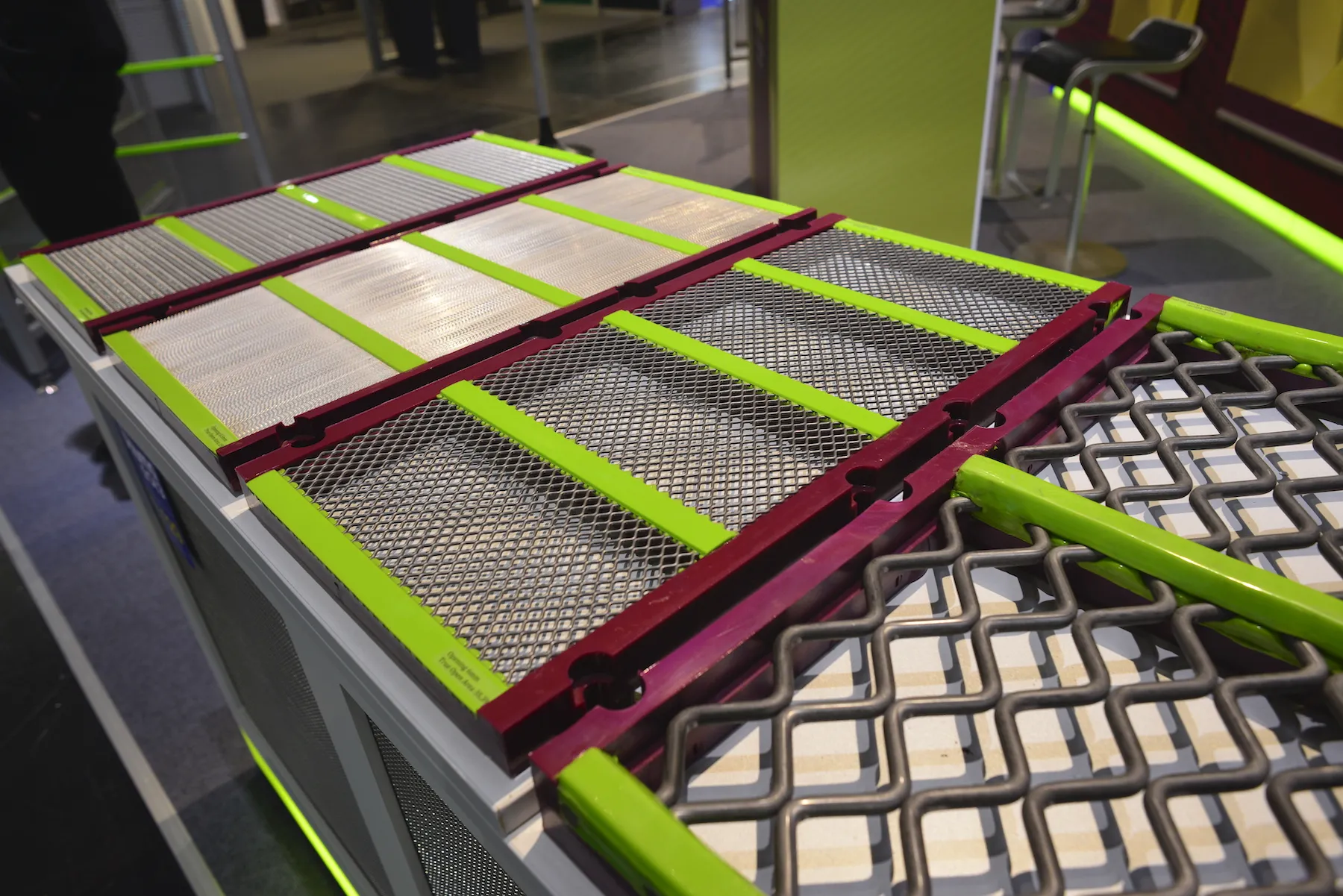

Nymølle Stenindustrier, a Denmark based gravel supplier, has replaced some of its screening media with Sandvik’s new WR Modular Screening Media. The modular construction of the new system meant that neither the frame, nor the screen, needed to be rebuilt, with a bonus being that the new screen is said to provide around 15% greater production capacity, with enhanced material separation, making the replacement a highly cost-effective investment.

September 19, 2012

Read time: 2 mins

The modular construction of the new system meant that neither the frame, nor the screen, needed to be rebuilt, with a bonus being that the new screen is said to provide around 15% greater production capacity, with enhanced material separation, making the replacement a highly cost-effective investment.

With around 25% of the Danish market, Nymølle Stenindustrier is one of Denmark’s largest suppliers of gravel.

Operating since 1909, the company now has 30 facilities in Fyn, Jutland and Själland, with a combined annual production of 7-8million tonnes of sand and aggregate. The produced materials are used for concrete structures, asphalt, road building, drains and other associated purposes.

Through its own laboratory, the company is able to analyse and check the materials produced, thus ensuring that customers receive high quality end products.

Nymølle Stenindustrier’s facility in Røde Kro near Aabenrå in Jutland produces around 250,000tonnes of material each year, of which 110,000tonnes are washed sand, with the remainder being aggregate.

During the summer of 2011, the facility identified a requirement to replace the screening media in one of the primary screens – a Svedala VFS 48/21 - which also operates as a washing screen. For a replacement the site’s production manager, Jens Rasmussen, contacted Sandvik Construction.