Africa is a market with enormous growth potential, and at bauma Africa, Beumer will be presenting its extensive capabilities in conveying, loading, palletising and packaging technology.

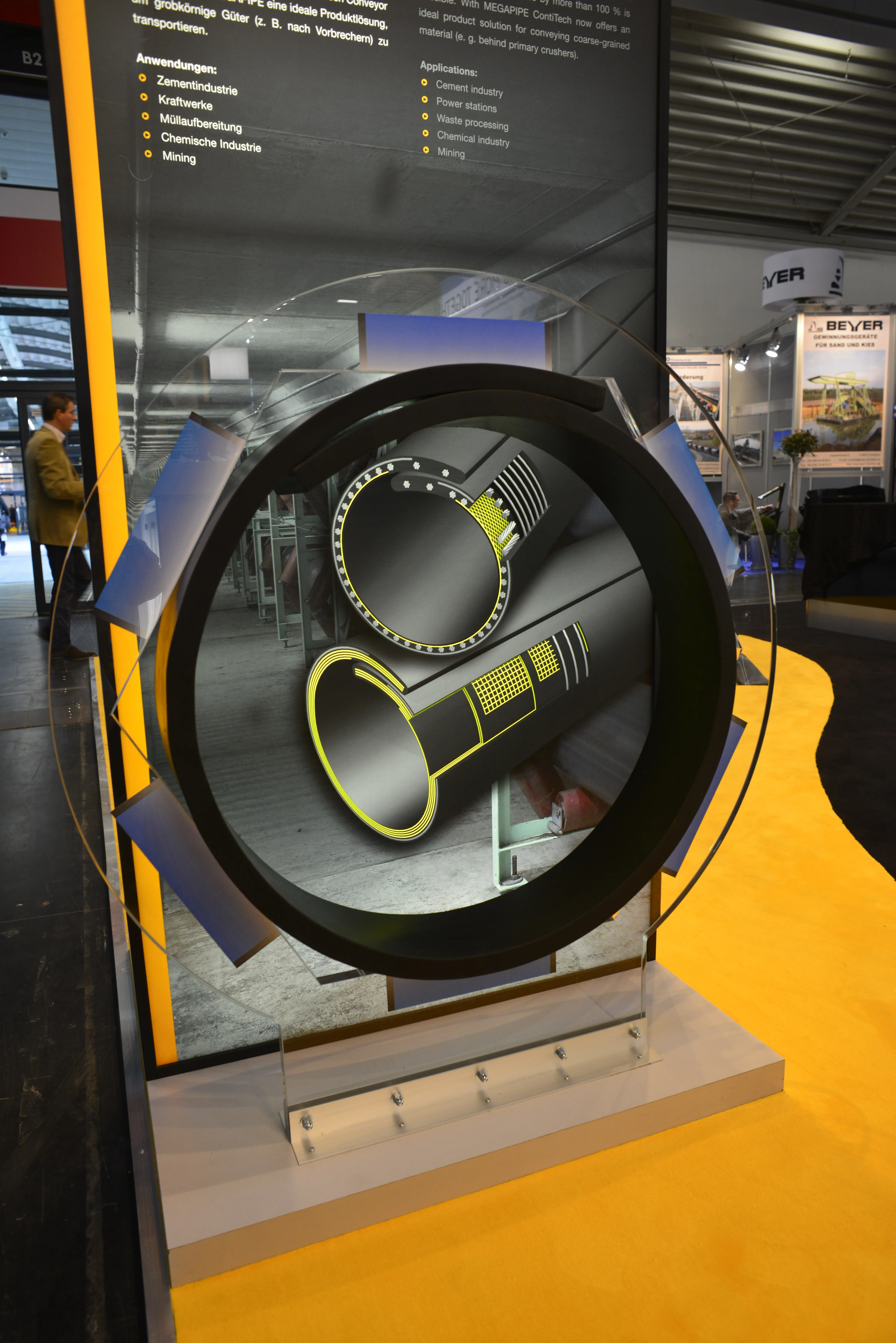

The Beckum, Germany-based group’s product range includes curved belt conveyors, among which are troughed belt conveyors and pipe conveyors, used for transporting various types of bulk goods over long distances.

August 27, 2013

Read time: 2 mins

Africa is a market with enormous growth potential, and at 7459 bauma Africa, 7303 Beumer will be presenting its extensive capabilities in conveying, loading, palletising and packaging technology.

The Beckum, Germany-based group’s product range includes curved belt conveyors, among which are troughed belt conveyors and pipe conveyors, used for transporting various types of bulk goods over long distances.

“BEUMER belt apron conveyors convey hot materials such as cement clinker safely and economically. They are based on the highly reliable belt technology used in bucket elevators,” says the group.

“Another product at the BEUMER stand, heavy-duty bucket elevators, can transport coarse and highly abrasive materials with pieces of up to 120mm in size.”

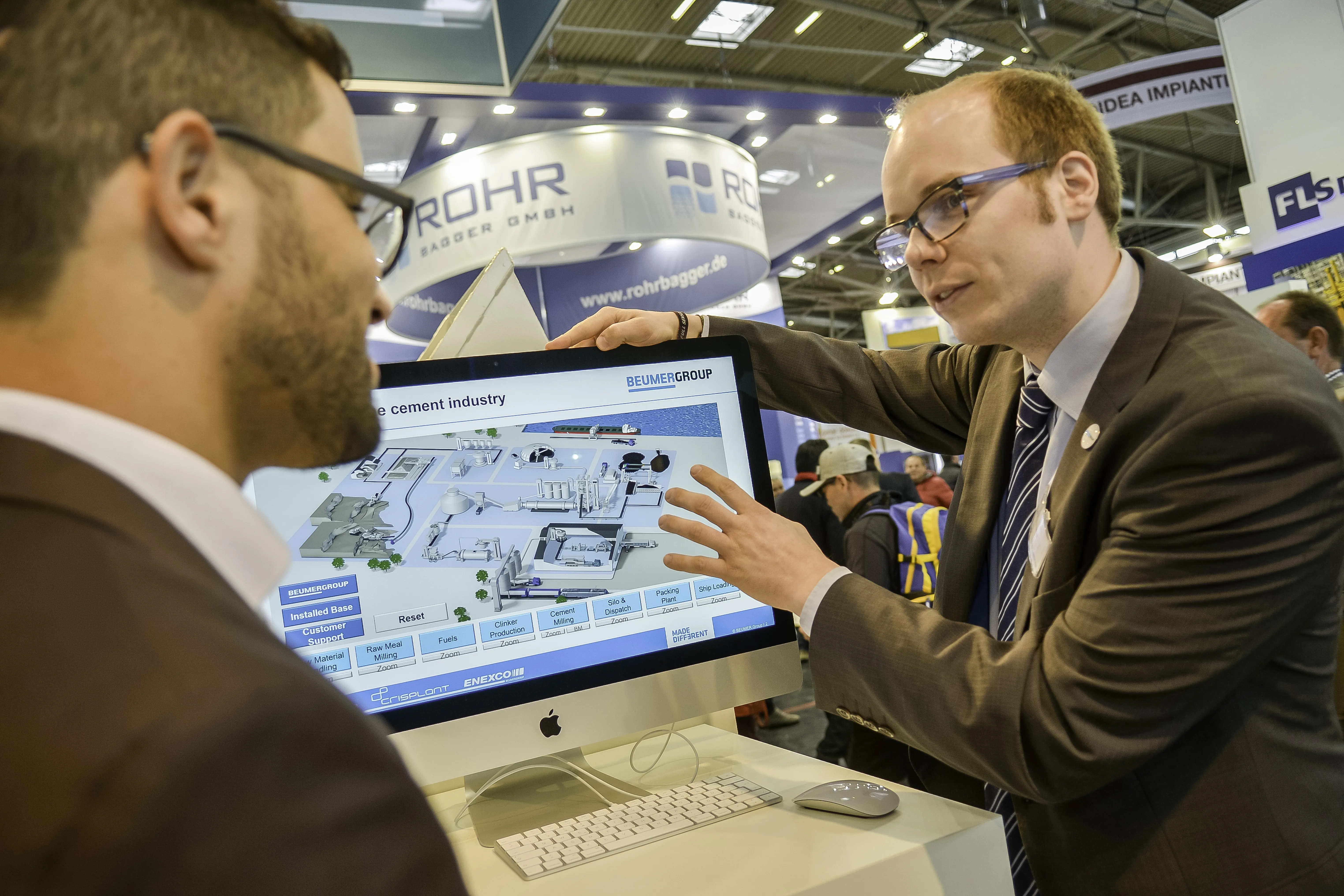

“When large volumes of material are handled such as in the cement industry, stationary loading heads are often inadequate because they have to move from one filling spout to the next on the vehicle,” says the group.

“In response, BEUMER has developed mobile loading units that can be adapted to the length of the vehicle”.

Stand: Hall H5, Stand 150

The Beckum, Germany-based group’s product range includes curved belt conveyors, among which are troughed belt conveyors and pipe conveyors, used for transporting various types of bulk goods over long distances.

“BEUMER belt apron conveyors convey hot materials such as cement clinker safely and economically. They are based on the highly reliable belt technology used in bucket elevators,” says the group.

“Another product at the BEUMER stand, heavy-duty bucket elevators, can transport coarse and highly abrasive materials with pieces of up to 120mm in size.”

“When large volumes of material are handled such as in the cement industry, stationary loading heads are often inadequate because they have to move from one filling spout to the next on the vehicle,” says the group.

“In response, BEUMER has developed mobile loading units that can be adapted to the length of the vehicle”.

Stand: Hall H5, Stand 150