Astec’s headline RAP plant can use up to 65% RAP content As it does for the 50% double barrel system aggregate dryer/drum mixer model, Astec is guaranteeing that its customers will get the increased percentage. The unit runs at 181-360tonnes/hour production (200-400UStons/hour). Astec, based in Chattanooga, Tennessee, manufactures all of their state-of-the-art Hot Mix Asphalt plants in the US. They introduced the first double barrel plant in 1989, according to executive vice president Steven Claude, during

June 23, 2015

Read time: 3 mins

RSSAstec’s headline RAP plant can use up to 65% RAP content

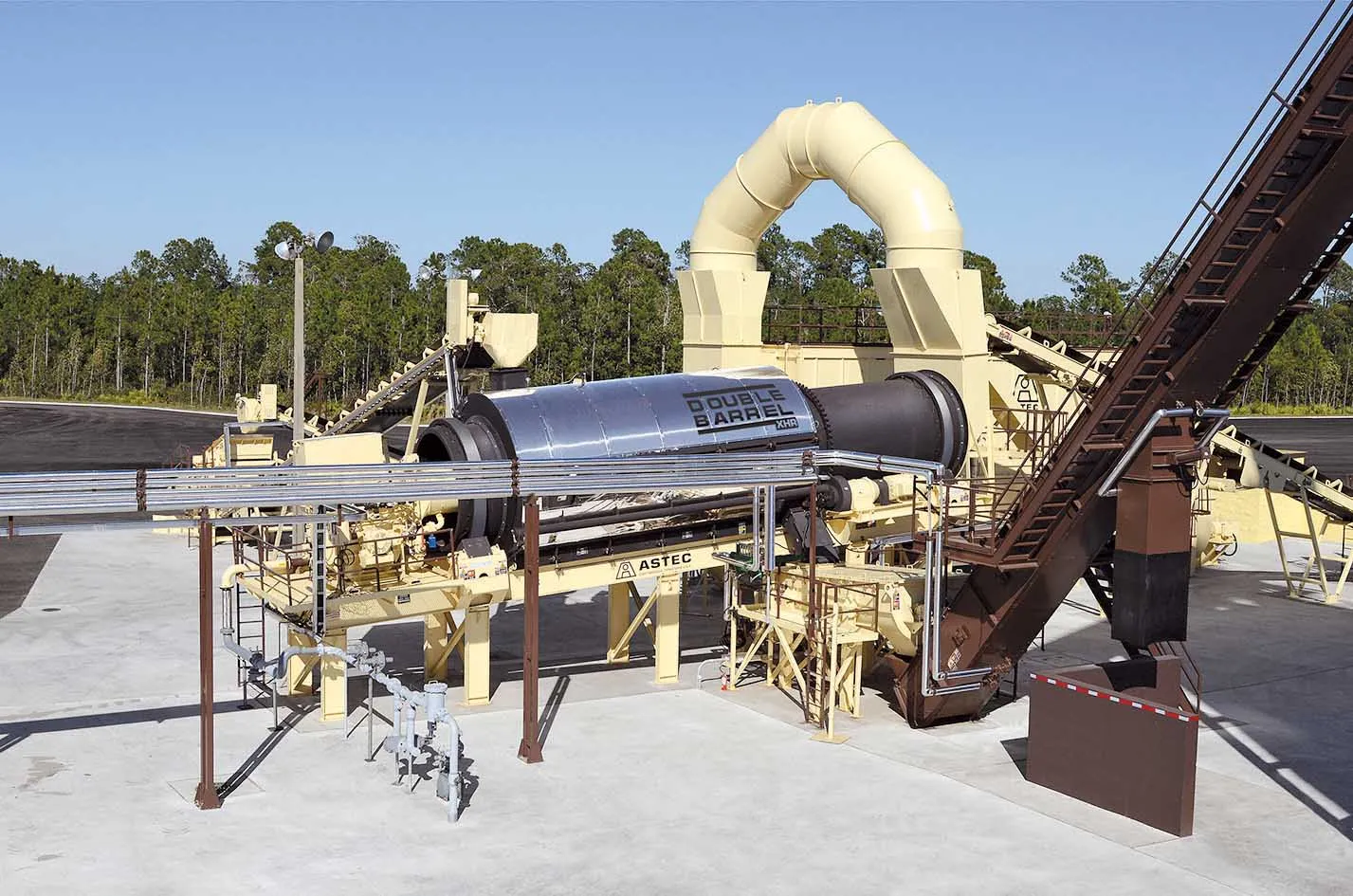

As it does for the 50% double barrel system aggregate dryer/drum mixer model,1250 Astec is guaranteeing that its customers will get the increased percentage. The unit runs at 181-360tonnes/hour production (200-400UStons/hour).

Astec, based in Chattanooga, Tennessee, manufactures all of their state-of-the-art Hot Mix Asphalt plants in the US. They introduced the first double barrel plant in 1989, according to executive vice president Steven Claude, during an interview at last month’s242 Intermat construction equipment exposition in Paris.

“We are now guaranteeing 65% on our new system,” he says, “however we will still continue to offer our traditional double barrel 50% model of which we have sold over 850 plants, and of which around 20% are outside the US.

“Customers will choose which plant best fits their needs depending on the amount of RAP available in their market. Every percent of RAP they use is sustainable and it also reduces cost, a win-win for the contractor and for the government that is funding the road project.”

The latest plant was introduced in the US in the third quarter and two have been sold. “We commissioned our first one in Daytona Beach, Florida, in March and we’re hitting our guarantees,” said Claude. “The second one in New York City was a retrofit and is being commissioned in May.”

Two primary changes to the plant design allow the increased use of RAP. “One, we’ve extended by six feet [1.8m] the internal drum where the drying takes place, so you get more drying time internally. Second, we add an external pugmill where the bitumen is injected for the actual mixing."

In addition, Astec has just introduced its patented ASTEC V-Pack Stack Temperature Control System which monitors the exhaust gas temperatures at the bag house inlet as the primary reference for control. As the exhaust gas temperature rises, the control system checks it against a set point.

When the temperature exceeds the set point, the control system speeds up the drum rotation, controlling temperature to the set point. The drum speed can be varied by the system from a minimum of about 7rpm to a maximum of about 12rpm; 8rpm is the normal speed for Astec drums without this system.

The combination of the new high rap design and the patented V-Pack enables Astec to meet the needs for higher RAP production and greater efficiencies that their customers have been asking for. “Astec will continue to maintain its focus on improving and enhancing their design to meet the needs of both their customers and the “green” standards being established worldwide targeted to protect our environment. Given the very positive reception we have received on our two most recent introductions of higher RAP capabilities and the V-Pack, we are convinced we are on the right track.”

As it does for the 50% double barrel system aggregate dryer/drum mixer model,

Astec, based in Chattanooga, Tennessee, manufactures all of their state-of-the-art Hot Mix Asphalt plants in the US. They introduced the first double barrel plant in 1989, according to executive vice president Steven Claude, during an interview at last month’s

“We are now guaranteeing 65% on our new system,” he says, “however we will still continue to offer our traditional double barrel 50% model of which we have sold over 850 plants, and of which around 20% are outside the US.

“Customers will choose which plant best fits their needs depending on the amount of RAP available in their market. Every percent of RAP they use is sustainable and it also reduces cost, a win-win for the contractor and for the government that is funding the road project.”

The latest plant was introduced in the US in the third quarter and two have been sold. “We commissioned our first one in Daytona Beach, Florida, in March and we’re hitting our guarantees,” said Claude. “The second one in New York City was a retrofit and is being commissioned in May.”

Two primary changes to the plant design allow the increased use of RAP. “One, we’ve extended by six feet [1.8m] the internal drum where the drying takes place, so you get more drying time internally. Second, we add an external pugmill where the bitumen is injected for the actual mixing."

In addition, Astec has just introduced its patented ASTEC V-Pack Stack Temperature Control System which monitors the exhaust gas temperatures at the bag house inlet as the primary reference for control. As the exhaust gas temperature rises, the control system checks it against a set point.

When the temperature exceeds the set point, the control system speeds up the drum rotation, controlling temperature to the set point. The drum speed can be varied by the system from a minimum of about 7rpm to a maximum of about 12rpm; 8rpm is the normal speed for Astec drums without this system.

The combination of the new high rap design and the patented V-Pack enables Astec to meet the needs for higher RAP production and greater efficiencies that their customers have been asking for. “Astec will continue to maintain its focus on improving and enhancing their design to meet the needs of both their customers and the “green” standards being established worldwide targeted to protect our environment. Given the very positive reception we have received on our two most recent introductions of higher RAP capabilities and the V-Pack, we are convinced we are on the right track.”