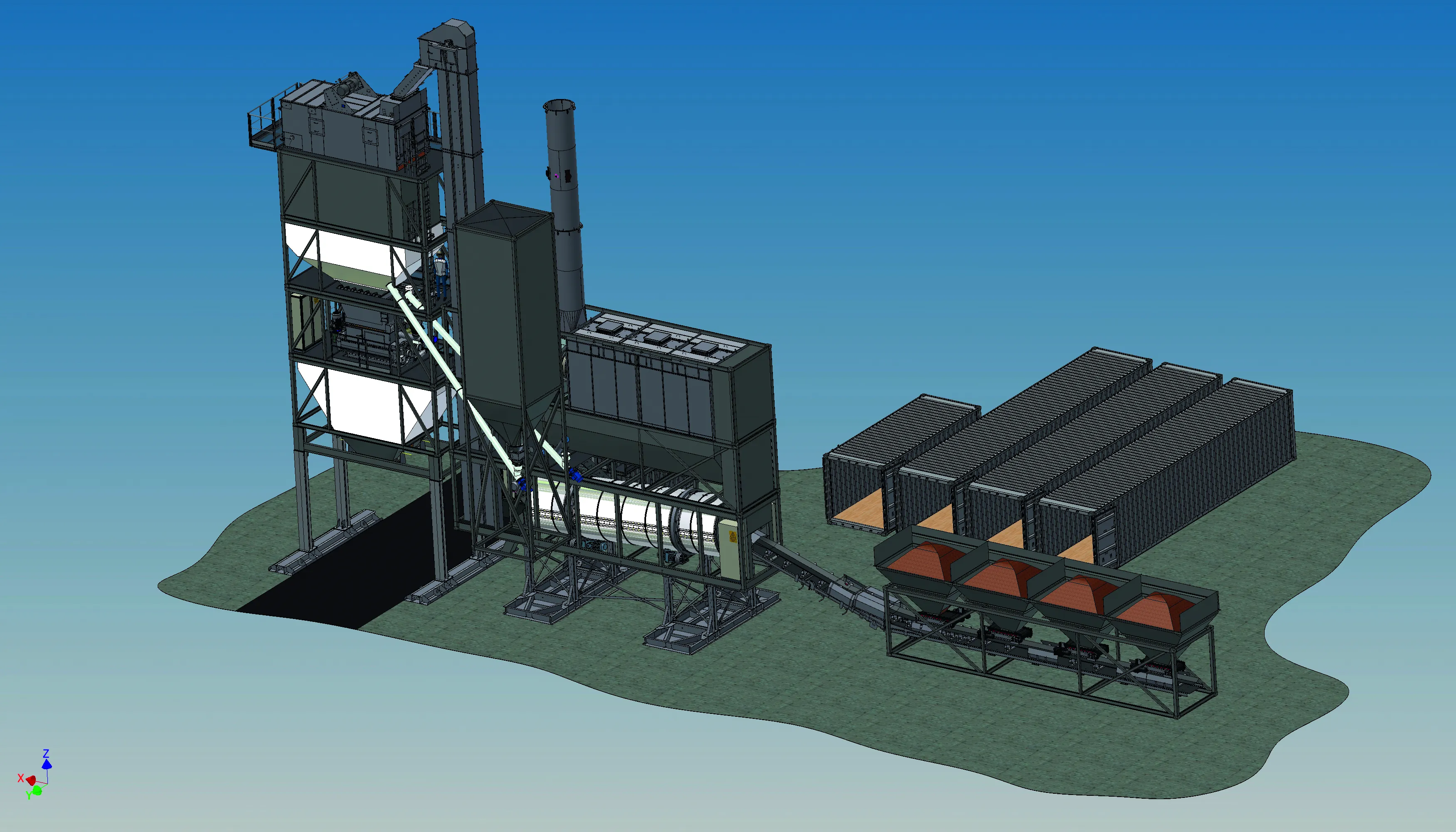

The JB150 plant being supplied is able to deliver up to 150tonnes/hour of asphalt and has been designed to meet the needs of customers in markets such as Asia. This features a 2tonne capacity mixer and has a standard configuration, with the Thai customer ordering the fixed version with a concrete base rather than the semi-mobile variant with a steel skid base.

Song Yik Chong, regional director for South East Asia commented, “It’s a standard design machine, which helps keep the price down. We still produce the main components at our factor in Switzerland like the dryer, the burner, the screen, the filter and the mixer. We send these to our factory in Shanghai to do the steelwork and the assembly.” He added the other components such as the cold feeder and bitumen tank are also built in China.

Ammann is gearing up its operations in South East Asia with a new office in Singapore, which will boost sales, marketing and support for parts and service. This operation will handle both the asphalt plants as well as the firm’s road machinery range, which it believes can attract additional sales in the region.