The Winterpave additive works by introducing chemicals that lower the freezing point of water on the road’s surface and lower the adherence between the ice and the surface. It can be pre-weighed and added to a mix in melting bags or via a dry dosing system and has already been trialled successfully in roads in Italy and in Anseong in South Korea.

There are several benefits to this new approach to de-icing. It acts immediately which lessens the risks of crashes and it reduces the need to use salt which can be damaging to the environment. It also removes the cost for salt spreading or snow ploughs and it can be used in difficult locations such as steep hills or tight spots.

In 2020, a section of the steep and winding SS24 highway in the Bozano region of Italy was resurfaced with a 50mm-deep layer of dense graded asphalt (12mm NMS) with a polymer-modified binder and 4.3% Winterpave. The asphalt for the section was subjected to extensive testing to ensure that it met the specification and to see how it performed with snow and ice on its surface. Specimens were put through freeze cycles in the lab and test slabs were placed outside in the snow. In both cases, the additive worked as planned.

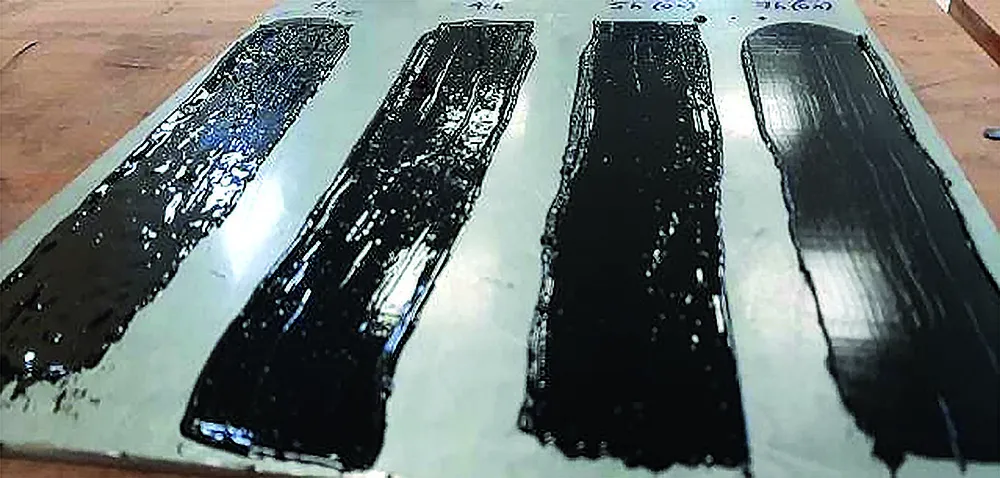

In Anseong, South Korea, strips of asphalt containing 4% of Winterpave were laid in at the entrance and exit to a logistics complex in Winter 2020. The strips remained clear of snow and ice, removing the need for maintenance operations and reducing the likelihood of accidents.