Vulcan Burners are enjoying continued success with proven results; the Vulcan burner has become the number one choice for major asphalt producers. With the successful implementation of burner replacement programs, our customers have effectively reduced their fuel costs and lower emissions. With this success, the Vulcan burner is now installed in over 20% of the UK asphalt industry in no less than 2 years! With orders placed already until the middle of next year, 2015 is set to emulate the success of the last two years!

We take huge pride in being completely honest with the customer and giving the accurate advice to the customer on where savings can be made across the asphalt plant. All advise and sales are explained from our engineering team so you can trust the information we provide. With any quotation process a complete technical site survey is carried out, so the quote you receive will have a full analysis of what to expect.

The Vulcan Burner range is versatile to all plant types and can offer applications for fuel oils, natural gas, LNG and LPG.

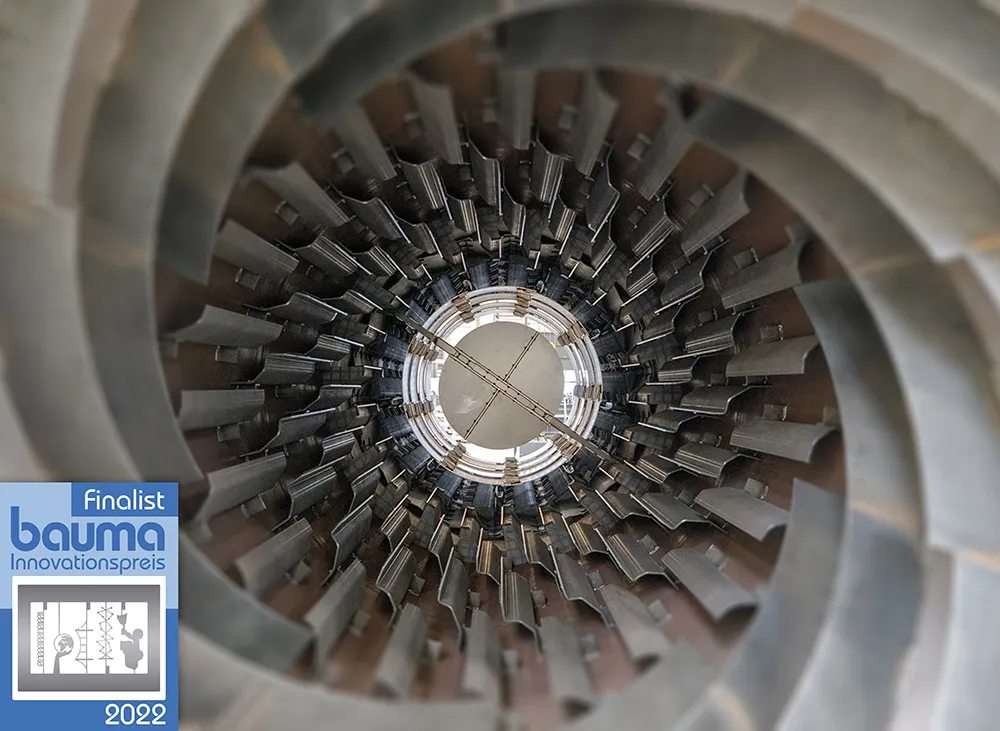

The Vulcan burner range, an efficient combustion solution for Asphalt plants and aggregate drying plants. Manufactured with the latest innovated technology, it is proven to reduce fuel costs for drying aggregates in the Asphalt Industry and has become the superior burner product throughout the UK.

Vulcan Burners have an established track record with major international operators offering significant and proven savings for asphalt operations. Innovative dual fuel technology, including natural gas, LNG and LPG pioneered by

Major operators include Aggregate Industries, Cemex UK Materials and Eurovia Infrastructure. Monitoring shows average fuel savings of 20 per cent. Vulcan Burners are based on experience of Asphalt Burner Services Ltd Engineers in asphalt burners of over 40 years that has enabled the company to develop burners with a unique and highly effective dryer combustion to optimise asphalt recycling and reduce carbon emissions.

The benefits of the installation of a Vulcan Burner include; Increased RAP production reduced fuel consumption, reduction in emissions and increased reliability of the burner.

Vulcan Burners scores success in UK asphalt

Vulcan Burners are enjoying continued success with proven results; the Vulcan burner has become the number one choice for major asphalt producers. With the successful implementation of burner replacement programs, our customers have effectively reduced their fuel costs and lower emissions.

April 16, 2015

Read time: 2 mins