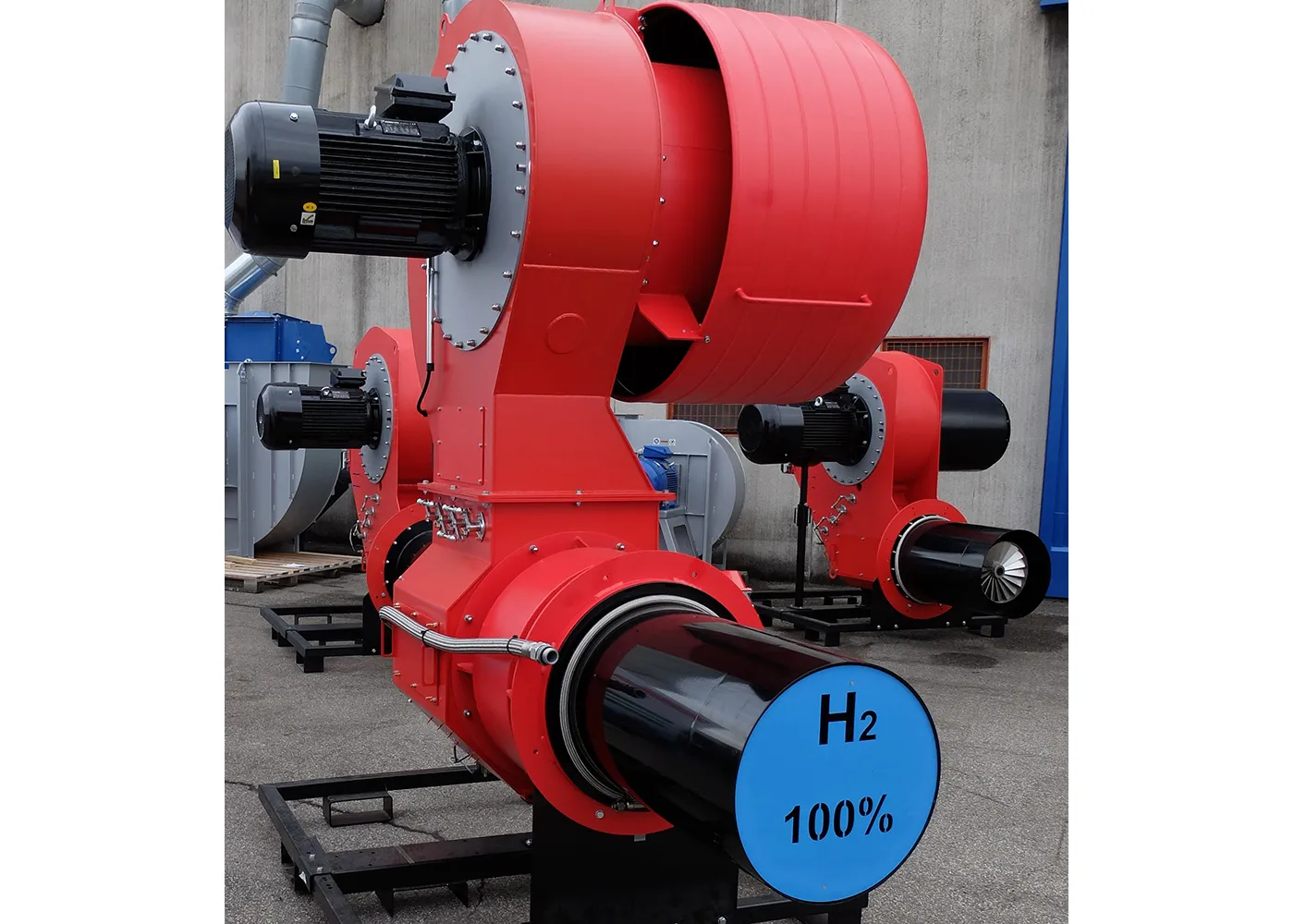

A revolutionary new asphalt plant burner from Ammann is claimed to be a world’s first as it can use hydrogen as fuel. This novel development forms part of the firm’s drive to develop green, sustainable solutions for the global construction industry.

“It is the first on the market. None of our competitors have it,” said Marzio Ferrini from Ammann and he added, “The hydrogen burner is available today.”

The new burner delivers precise control of the flame shape and an optimised air/fuel mix to increase combustion efficiency. It has redesigned electronics and mechanical components to ensure ease of maintenance. Using a fuel supply of 100% hydrogen, the burner operates cleanly. The system is available as a retrofit and can also be used to burn a combination of hydrogen and natural gas to meet available supplies.

Hydrogen is the world’s most common element and is non-toxic. “After combustion we have only water vapour,” Ferrini said.

The burner has been developed with a view to the future. Industrial operations are being taxed for CO2 emissions in Europe and this is coming for China also, with similar moves likely elsewhere in the world in due course.

Ferrini said, “We are working to reduce the environmental impact of asphalt plants to zero.”

Other developments from Ammann for making asphalt plants cleaner include innovative technologies to minimise smoke and particle emissions. The technology uses a combination of filtration and recirculation to remove up to 70% of emissions. Smoke is captured, rerouted and reused while the oily particles are filtered from the stream at a number of stages. The oil is then condensed and can also be reused, while the filters are said to be self-cleaning with minimal maintenance needs. The technology helps to increase plant efficiency also and Ferrini commented, “We are saving energy because we are reusing the hot air.”

Combined with the new hydrogen burner, these reduced emission systems will help to reduce the environmental impact of an asphalt plant significantly.

One of the biggest challenges to the use of the hydrogen burner at present is the availability of ‘green’ hydrogen derived from electrolysis using sustainable energy sources. But this sector is growing, especially as a number of engine firms such as Cummins, Kohler and Perkins (Caterpillar) are actively developing power units running on hydrogen. Construction machinery firms including Hyundai, JCB and Komatsu are already well down the path to offering equipment fuelled by hydrogen. Cummins in particular has invested in the electrolysis technology segment and is now constructing plants for the production of green hydrogen.