Haver & Boecker claims that its NIAflow plant simulation software can help producers optimise quarry operations. The company is also offering new screening grid options that can improve screening performance.

The NIAflow package can be used to boost the efficiency of plant throughput, realign machine location and deliver product pre-calculations. This package can be used for existing or proposed processes and records plant status as well as identifying plant optimisation options. The software is availabl

January 30, 2017

Read time: 2 mins

The NIAflow package can be used to boost the efficiency of plant throughput, realign machine location and deliver product pre-calculations. This package can be used for existing or proposed processes and records plant status as well as identifying plant optimisation options. The software is available for download on Windows-based systems and can allow the user to draft flow diagrams for product pre-calculation or simulate parameter changes. NIAflow allows users to analyse more than 90 process equipment pieces, from crushers and vibrating screens to material washers and conveyers. Beyond equipment, the system uses scientific-based methods to monitor the operation’s input, output and waste piles. The program calculates the mass and volumetric flow rates as well as the valuable content with machine-specific operating parameters to prevent plant bottlenecks.

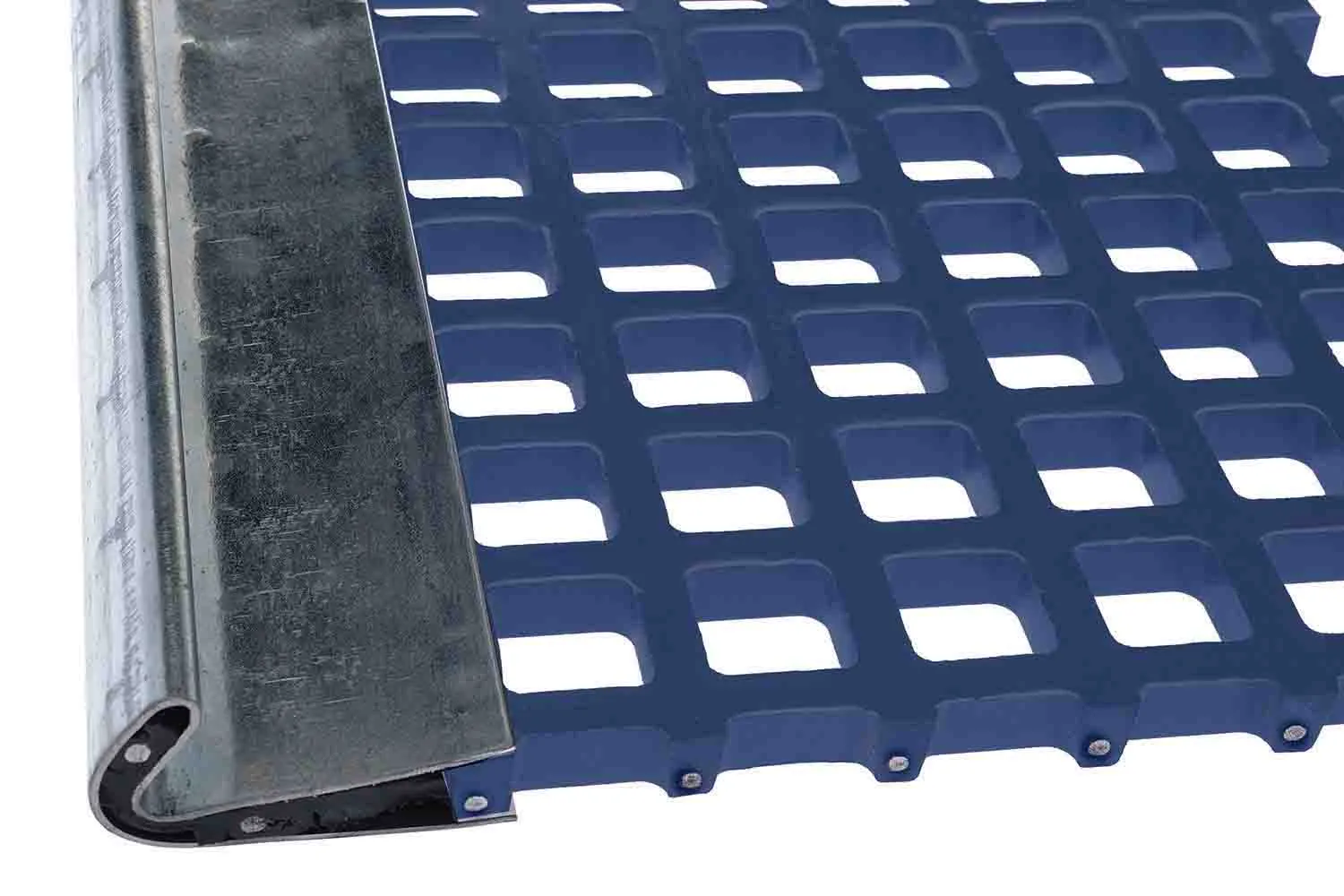

In addition the firm says that its Tyler brand of hooked engineered screen media offers a solution to deck conversions. Tensioned screen media can be used on a cambered deck, eliminating the need for a deck conversion when switching from woven wire to polyurethane screen media.

Hooked screen media allows operations to switch from woven wire to modular polyurethane products without the expense of a deck conversion. Another benefit is that the new Ty-Max and Ty-Wire products can be blended with woven wire or self-cleaning screens on cambered decks. These products can also deliver more wear life on the feed end of the screen according to the firm.