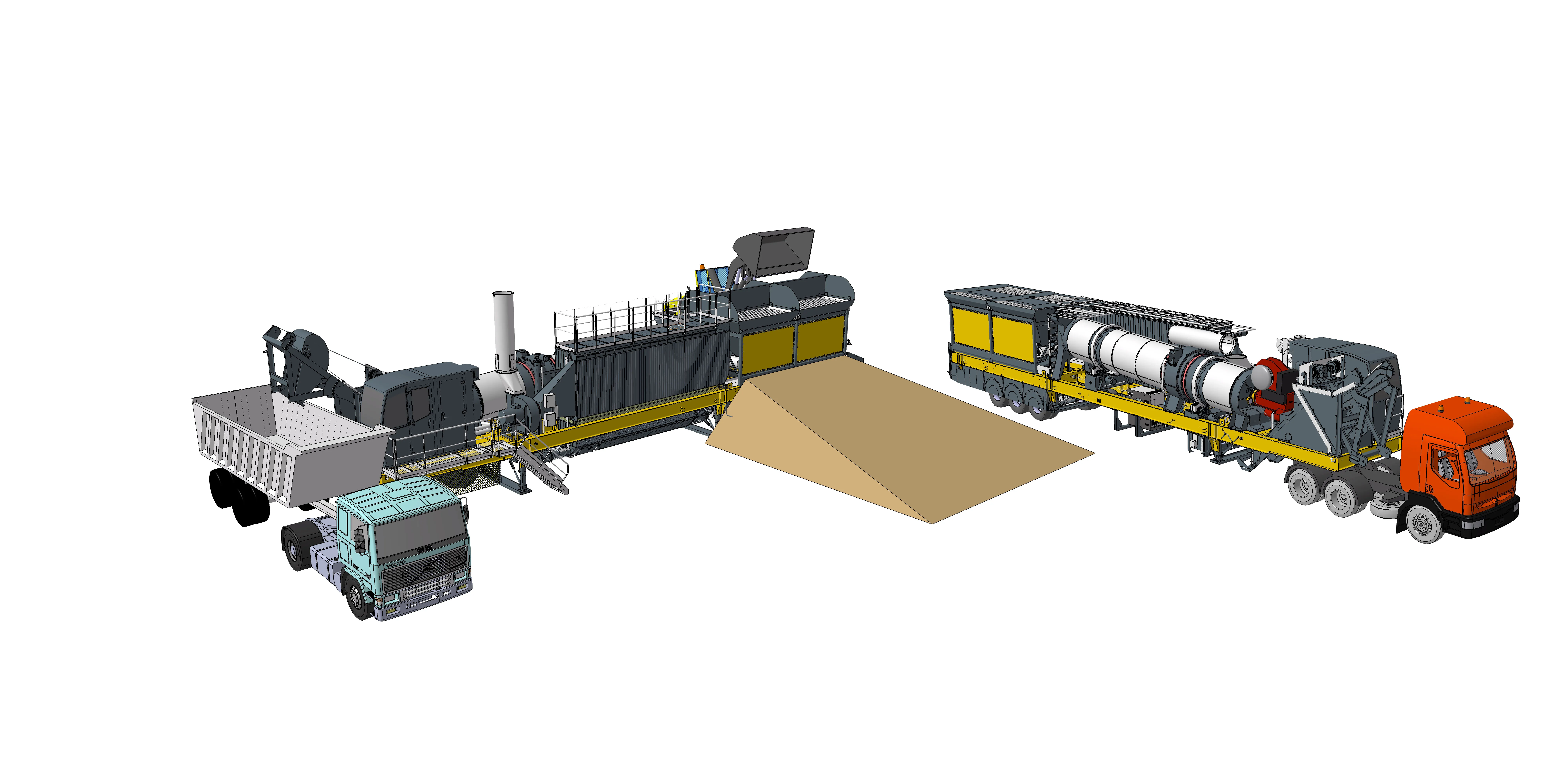

The Fayat Group has won an Intermat innovation award for its new TRX100 asphalt plant. The new design from the firm was the winner of Equipment & Machinery Award in the Roads, Minerals and Foundations category, which was awarded on 18th January 2018. The TRX100 is a new mobile continuous asphalt plant able to handle up to 100% recycled material in its feed supply. Designed for fast relocation, the machine features an innovative low temperature production process.

January 22, 2018

Read time: 1 min

The 2779 Fayat Group has won an 242 Intermat innovation award for its new TRX100 asphalt plant. The new design from the firm was the winner of Equipment & Machinery Award in the Roads, Minerals and Foundations category, which was awarded on 18th January 2018. The TRX100 is a new mobile continuous asphalt plant able to handle up to 100% recycled material in its feed supply. Designed for fast relocation, the machine features an innovative low temperature production process.

Other innovation award winners include