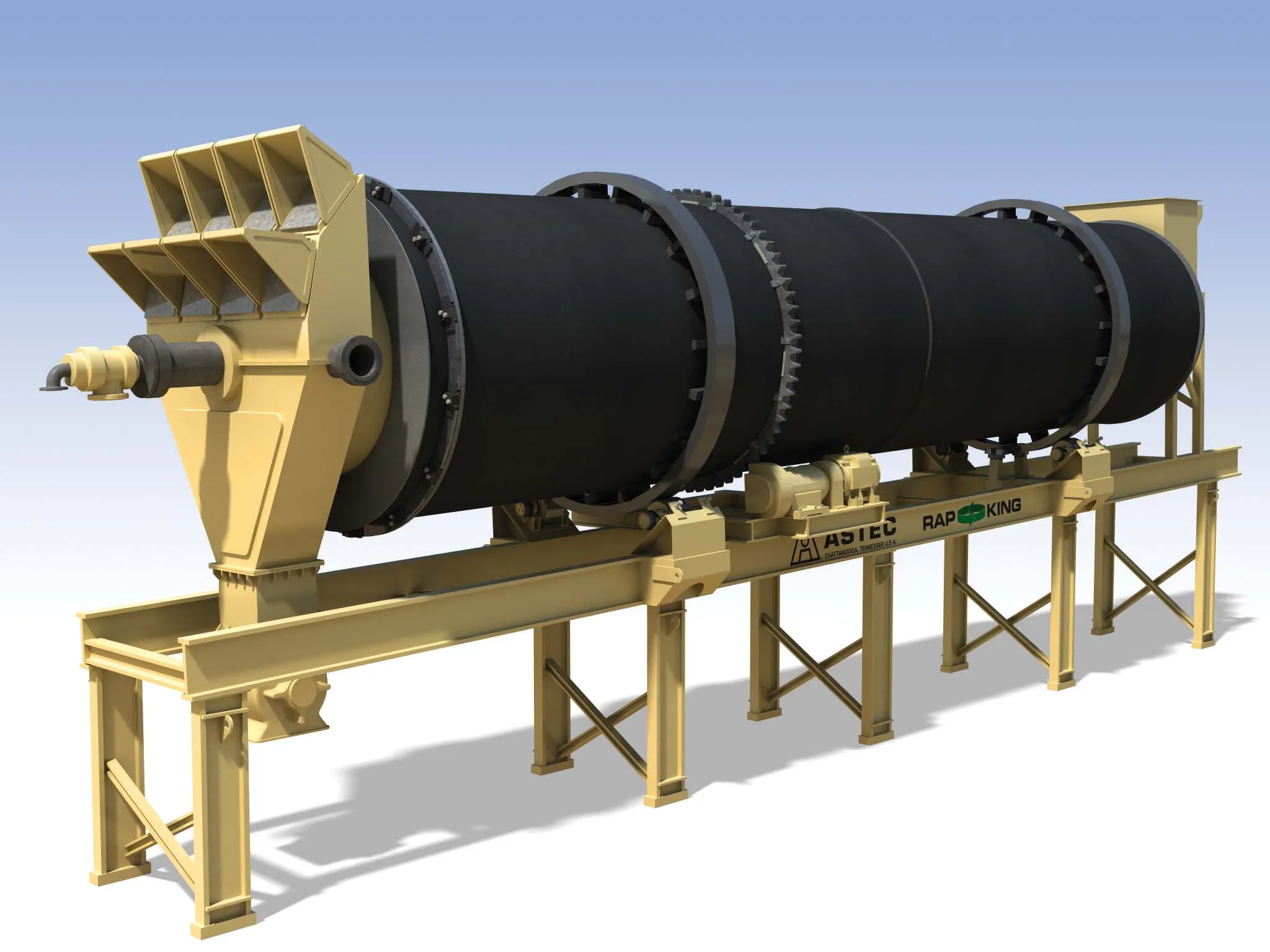

The latest asphalt plant from

A key feature of the plant according to the firm is the air suction system installed at several key points to help with pollution control. The separate baghouse filter for the cold feeder section is equipped with automatic sensors that are activated when aggregates are being loaded into the system using a wheeled loader. This baghouse filter also picks up dust from the collecting belt as well as the throw belt, further improving the environmental performance of the whole system.

The revised baghouse filter system has been modified to ensure that the bitumen fumes and odour emissions are minimised. In addition, bitumen fumes emitted from the bitumen tanks and mixer discharge are absorbed through a ducting system. This utilises injections from fine fillers to absorb any oil droplets in the air, before being processed in a baghouse filter. The fumes are then filtered using a special low temperature plasma process that is said to be highly efficient. The special plasma system breaks down the molecules to remove the odour.

Lintec has already supplied its first CSM4000 plant to a Chinese customer, a large system capable of producing up to 320tonnes/hour. With its low emissions technology, this plant also meets the increasingly tough requirements from the Chinese authorities on reducing smoke, fumes and dust emissions from asphalt plants.