Bunting Magnetics celebrated 60 years in business by supplying a one of the largest quarries in the US state of Georgia with a Bunting PCB1206-EL <%$Linker:

Junction City helps build bridges in the US southeast by supplying high-quality aggregate materials for construction. The company required a massive structure to handle the minerals the company supplies for asphalt and concrete to construction companies throughout the states of Florida and Georgia.

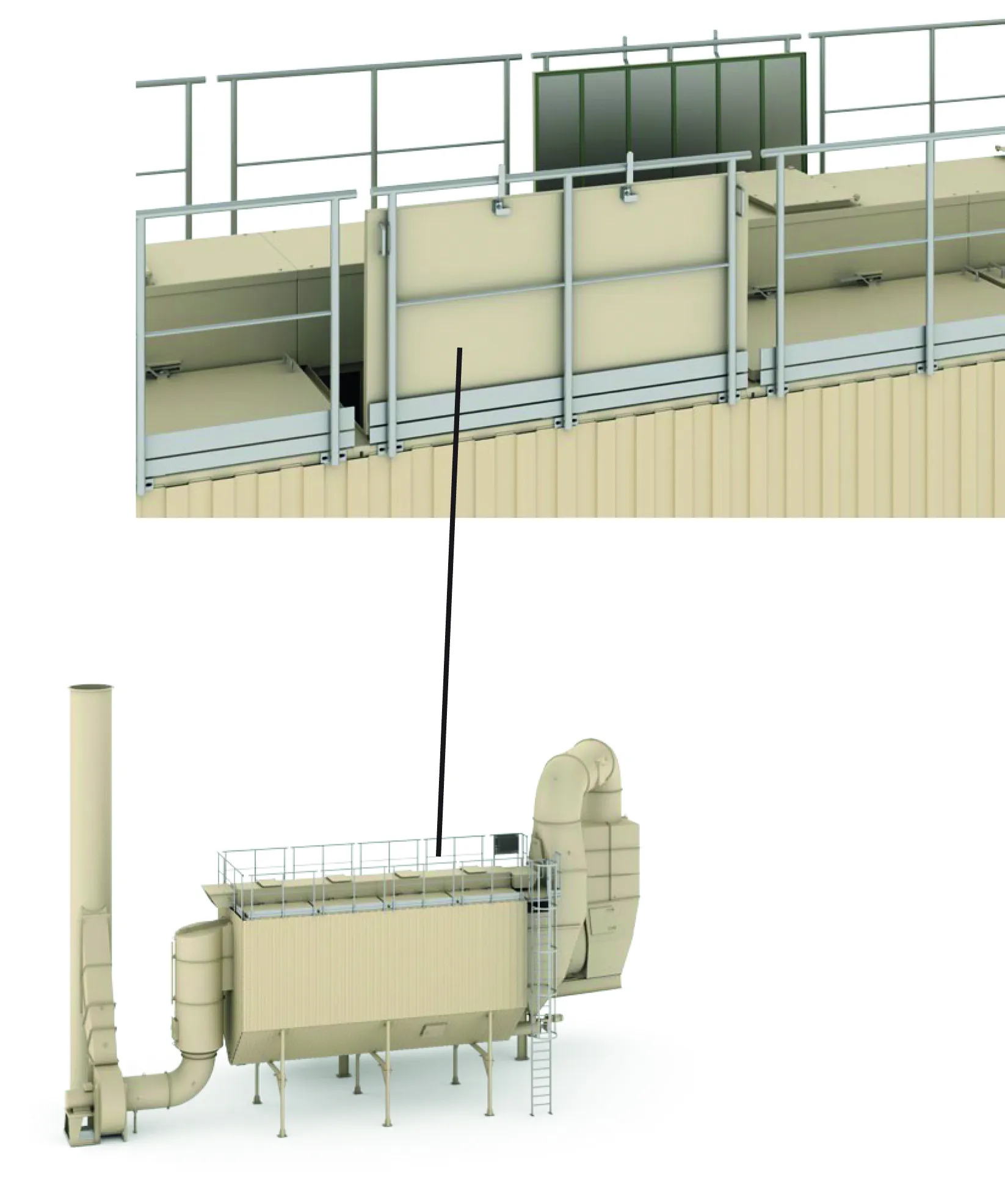

Bunting’s engineers presented them with the custom-designed Permanent Crossbelt Separator equipped with a massive 813mm conveyor. It boasts 280mm burden depth, extracting between 7-11kg of tramp metal at a time. The conveyor processes 3.6-to 450 tonnes of granite per hour, separating out tramp metal consisting of wear parts, bolts, and other scrap material that would detract from Junction City Mining’s high standard of quality if it were to remain in their product.

“It’s pulling blasting cap and all the dimensional tramp we were expecting,” said Josh Conrad, mine engineer and superintendent of Junction City Mining.

The powerful magnet block of the permanent crossbelt separator is mounted in a heavy-duty steel frame and traversed with a vulcanized, cleated belt that runs on two crowned pulleys. Bunting says that the unit’s self-cleaning system minimises downtime and improves operational efficiency, which is increased even further by the low-maintenance requirements of the separator.

Bunting Magnetics is headquartered in Newton, Kansas with manufacturing and distribution facilities across the US and IK. “I think it’s very exciting that we’ve been able to achieve 60 years in business as a private, family owned company. It speaks very well to the dedication of our employees and the Bunting family as a whole,” said Bob Bunting, son of the founder and now president of the company.