The first motorway connecting the cities of Hyderabad-Bangalore will be approximately 600km long, with three lanes in both directions. It will represent an important change in India as the country will benefit from a fast and greater flow of communication, transportation and commerce networks, which up until now have been carried out mainly by sea.

April 13, 2012

Read time: 2 mins

The first motorway connecting the cities of Hyderabad-Bangalore will be approximately 600km long, with three lanes in both directions.

It will represent an important change in India as the country will benefit from a fast and greater flow of communication, transportation and commerce networks, which up until now have been carried out mainly by sea.

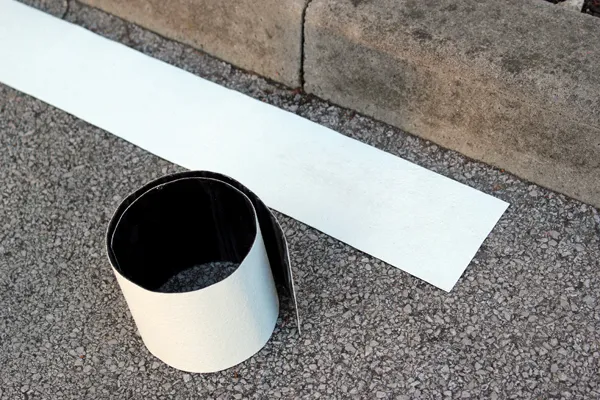

Italian company283 MB is supplying crusher buckets to help build the motorway: the BF120.4 bucket will be used to produce the stabilised pavements every 50km.

According to MB a feature of the BF120.4 is that it is the only piece of equipment capable of reducing the size of crushed granite from 20cm to 4cm, thus "making the job easier and more versatile." The Breganze-based company (currently in the process of obtaining the ISO 14001 certification) says that its buckets work using the hydraulic system of the excavator they are fitted to, and, "unlike traditional crushers, offer significantly reduced transportation and waste disposal costs, thus allowing inert materials to be recycled." Guido Azzolin, managing director of MB, said: "We are extremely optimistic on the successful outcome of the motorway that will connect the cities of Hyderabad and Bangalore, both extremely excited to try out our highly technological, Italian-made buckets and to obtain a new communication line that we are sure will be appreciated by the Indian country."

It will represent an important change in India as the country will benefit from a fast and greater flow of communication, transportation and commerce networks, which up until now have been carried out mainly by sea.

Italian company

According to MB a feature of the BF120.4 is that it is the only piece of equipment capable of reducing the size of crushed granite from 20cm to 4cm, thus "making the job easier and more versatile." The Breganze-based company (currently in the process of obtaining the ISO 14001 certification) says that its buckets work using the hydraulic system of the excavator they are fitted to, and, "unlike traditional crushers, offer significantly reduced transportation and waste disposal costs, thus allowing inert materials to be recycled." Guido Azzolin, managing director of MB, said: "We are extremely optimistic on the successful outcome of the motorway that will connect the cities of Hyderabad and Bangalore, both extremely excited to try out our highly technological, Italian-made buckets and to obtain a new communication line that we are sure will be appreciated by the Indian country."