The Ammann Group has acquired concrete plant manufacturer Elba in a move said to ‘round off’ the Group’s portfolio, while also representing an ideal complement to Ammann’s existing asphalt plant and machine divisions.

Founded in 1948, Elba is based in Ettlingen, Germany and is considered a much-respected producer of high-quality concrete mixing plants. Ammann will complete the actual purchase process at the beginning of March 2014 once the acquisition has been approved by the cartel authorities.

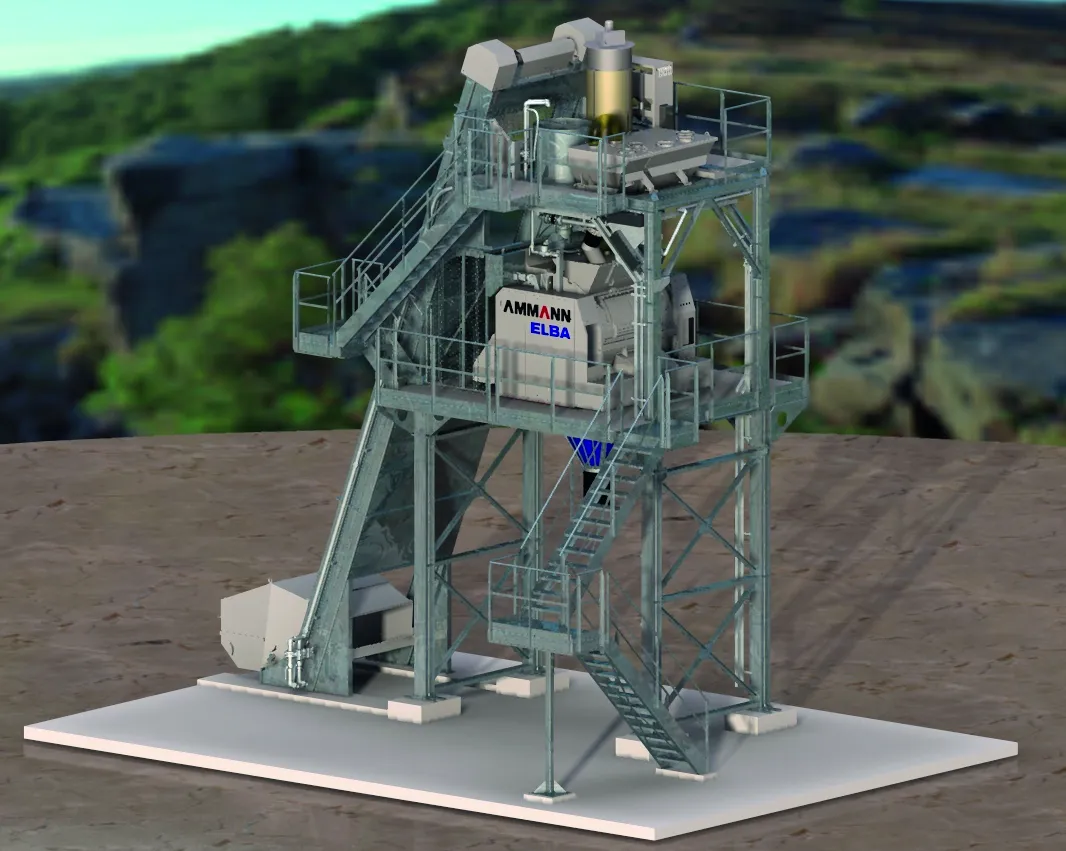

The Elba

February 11, 2014

Read time: 2 mins

The Ammann Group has acquired concrete plant manufacturer Elba in a move said to ‘round off’ the Group’s portfolio, while also representing an Ideal complement to Ammann’s existing asphalt plant and machine divisions.

Founded in 1948, Elba is based in Ettlingen, Germany and is considered a much-respected producer of high-quality concrete mixing plants. Ammann will complete the actual purchase process at the beginning of March 2014 once the acquisition has been approved by the cartel authorities.

The Elba acquisition will strengthen Ammann’s position on the international market for concrete mixing plants. For decades, Ammann says customers in Central Europe, Russia/CIS, Middle East and North Africa have appreciated the Elba brand for its high-quality concrete mixing plants equipped with internationally proven German technology.

All Elba plant parts and components are developed, designed and manufactured in Ettlingen by a team of around 130 qualified employees. As Ammann is taking on the existing, well-oiled management crew, the subsidiary in Ettlingen will become the concrete centre of the Ammann Group.

The Ammann Group and Elba have agreed not to disclose the purchase price.

Hans-Christian Schneider, Ammann Group CEO, said, “We are delighted to have found in Elba the ideal partner in the concrete plant segment. We are now in a position to meet the needs of our customers worldwide with well-established, high-quality concrete plants developed and manufactured in Germany.”

Axel Bullinger, former managing director of Elba and now managing director of the new Ammann subsidiary in Ettlingen, said, “Integration into the Ammann Group and investments in the site will provide the security and opportunity to continue improving and marketing our products in the long term under the roof of a globally operating corporation.”

Founded in 1948, Elba is based in Ettlingen, Germany and is considered a much-respected producer of high-quality concrete mixing plants. Ammann will complete the actual purchase process at the beginning of March 2014 once the acquisition has been approved by the cartel authorities.

The Elba acquisition will strengthen Ammann’s position on the international market for concrete mixing plants. For decades, Ammann says customers in Central Europe, Russia/CIS, Middle East and North Africa have appreciated the Elba brand for its high-quality concrete mixing plants equipped with internationally proven German technology.

All Elba plant parts and components are developed, designed and manufactured in Ettlingen by a team of around 130 qualified employees. As Ammann is taking on the existing, well-oiled management crew, the subsidiary in Ettlingen will become the concrete centre of the Ammann Group.

The Ammann Group and Elba have agreed not to disclose the purchase price.

Hans-Christian Schneider, Ammann Group CEO, said, “We are delighted to have found in Elba the ideal partner in the concrete plant segment. We are now in a position to meet the needs of our customers worldwide with well-established, high-quality concrete plants developed and manufactured in Germany.”

Axel Bullinger, former managing director of Elba and now managing director of the new Ammann subsidiary in Ettlingen, said, “Integration into the Ammann Group and investments in the site will provide the security and opportunity to continue improving and marketing our products in the long term under the roof of a globally operating corporation.”