A Lintec CSD3000 containerised asphalt plant, the largest mixing plant in the country, has been key to producing its new, premium-quality racetrack in record time in Indonesia. Two Linnhoff TSD1500 MobileMix asphalt plants were also used to produce the asphalt mix for the run-off areas.

The Lintec CSD3000 asphalt plant supplied more than 50,000tonnes of hot mix asphalt from the highest quality materials for the high-profile project. The premium stone mastic asphalt (SMA) material is used for the surface layer of the new track on Lombok Island, making the circuit one of the few to adopt this harder-wearing technology.

The construction work on the 4.31km Pertamina Mandalika International Street Circuit on Lombok Island’s southern coast began in June 2020, as part of the Indonesian government’s campaign to promote international tourism. Paving works began in February 2021 and continued until August 2021, with the entire project being completed by October 2021. The circuit was ready to host its first race, the finale of the FIM Superbike World Championship (WorldSBK) season, during November 19th-21st 2021.

The motorcycle racers took advantage of the high-quality track surface and the final round of the 2021 World Superbike Championship was notable, with Toprak Razgatlioglu becoming the first ever Turkish WorldSBK champion.

As the resort area of Mandalika continues its transformation into a tourist area rivalling nearby Bali, the track has become the only street circuit in the prestigious MotoGP calendar used as an ordinary road when no events are scheduled.

The surface layer is paved using the SMA mixture, which combines the tough coarse aggregate Tau stone from Palu, Central Sulawesi, with performance grade (PG) 82 polymer-modified bitumen (PMB). Also added was limestone filler from Ponorogo and Probolinggo, East Java, and cellulose fibre additives from Germany. Only premium quality materials were used for the asphalt mixes. By strengthening the structure of the surface layer so that it remains strong through stone-by-stone contact, the high cohesive strength provides greater resistance to intense heat and heavy loads. By remaining non-slippery in wet conditions, this mix is highly suitable for racetracks in tropical regions.

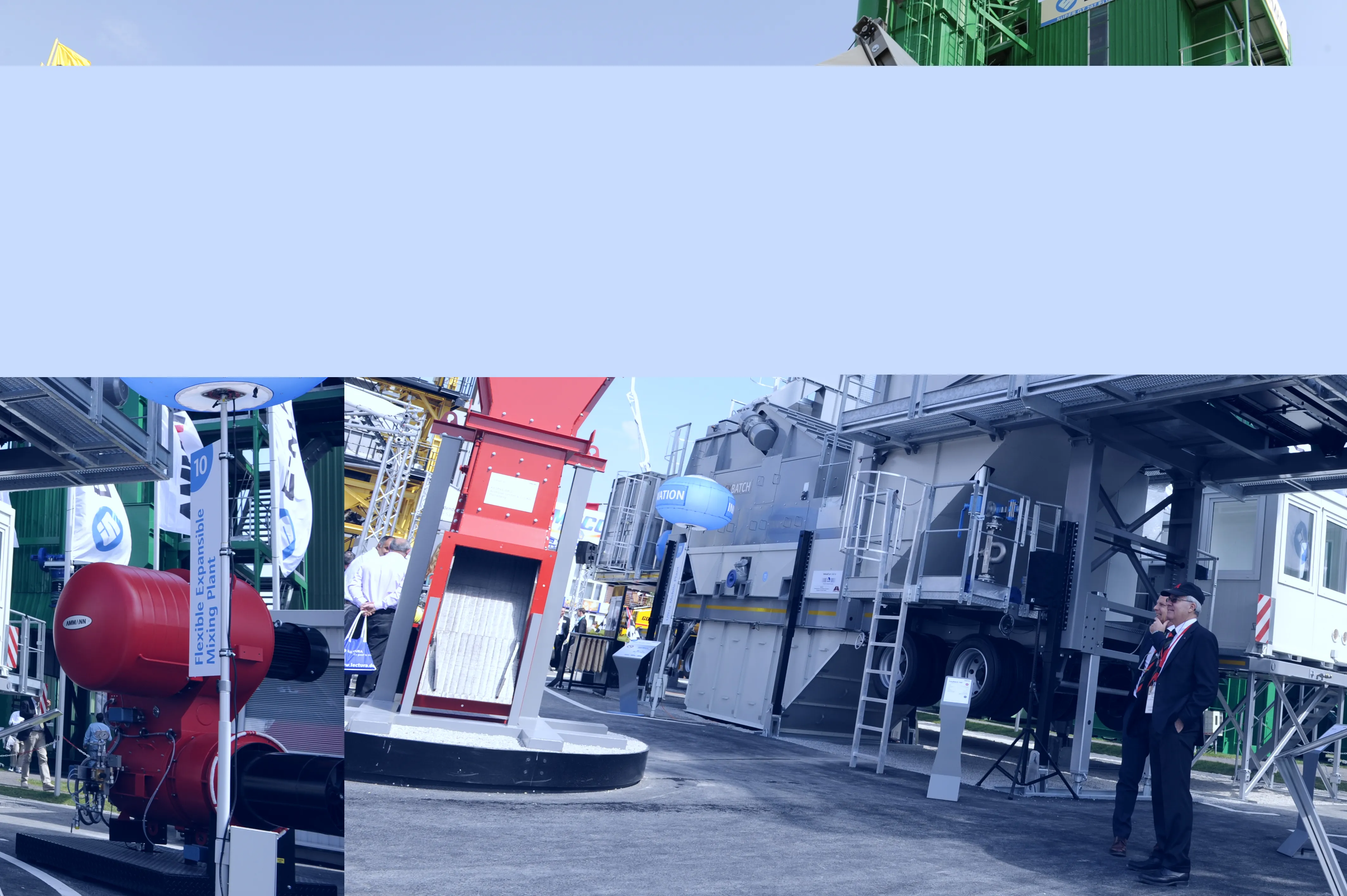

With its effective screening, accurate weighing, proper and efficient drying, and a production output of up to 240tonnes/hour, the Lintec CSD3000 plant proved valuable for the project. The high capacity asphalt plant was chosen to minimise the paving joints for a smoother racetrack surface. With the PG 82 PMB providing improved workability of asphalt mixtures, it was crucial that the contractors used a plant that could provide homogeneous output to ensure a reliable, optimum mix.

The plant produced over 50,000tonnes of hot mix asphalt for the three layers of the main track; namely the asphalt concrete (AC) base layer; AC binder layer; and the SMA surface layer.

Lintec & Linnhoff said that the contractors appreciated the consistent quality of the finished mix. In addition, the novel double screen drum technology allowed energy savings as there is no hot elevator or vibrating screens, while also boosting higher reliability and requiring less maintenance.

The Lintec CSD3000’s modular construction means that the plant is built inside ISO shipping containers for safe, economical transportation, which cut installation and commissioning times after the equipment was delivered to the jobsite.

The Lintec CSD3000 was joined onsite by two Linnhoff TSD1500 MobileMix asphalt plants. These mid-size models of the range produced 90-100tonnes of hot mix asphalt/hour, and were primarily used to produce material for the run-off areas around the main track.

These areas also play host to a large paddock area containing 40 garages, along with temporary grandstand seating for 50,000 fans and 7,700-person capacity hospitality suites, all of which will be removed at the end of each race. There is also a standing area catering for 138,000 spectators.

Operated by the Mandalika Grand Prix Association (MGPA), the generally flat circuit features 17 turns, with just a few hard braking areas.

The circuit has met the Fédération Internationale de Motocyclisme (FIM) Class A level and will play host to the prestigious MotoGP in March 2022. The operator is also aiming to meet the Fédération Internationale de l’Automobile (FIA) Grade 1 level to be eligible as a potential future Formula 1 venue.