Concrete production technology is advancing as new systems come to market – Mike Woof reports

The efficient production of high-quality concrete is crucial to many construction projects. Whether high-output plants are being used for large bridge or tunnel projects, or smaller mobile units are being used to supply specific operations such as central reservation barrier installation, the quality of the product is vital. Production technology has improved across the board due to the introduction of new systems.

The latest generation plants feature sophisticated controls to ensure that the output meets the necessary specifications and is also homogenous. For the largest plants, throughput is a major focus while for smaller batching plants, high mobility is key. In the latter instance, firms are now taking advantage of new electronics as well as improvements in hydraulics that allow them to integrate separate units together for greater overall performance.

These mobile units can also be delivered inside standard shipping containers, making them easier to transport, whether by road, rail or sea.

In the mobile equipment sector, Swiss firm

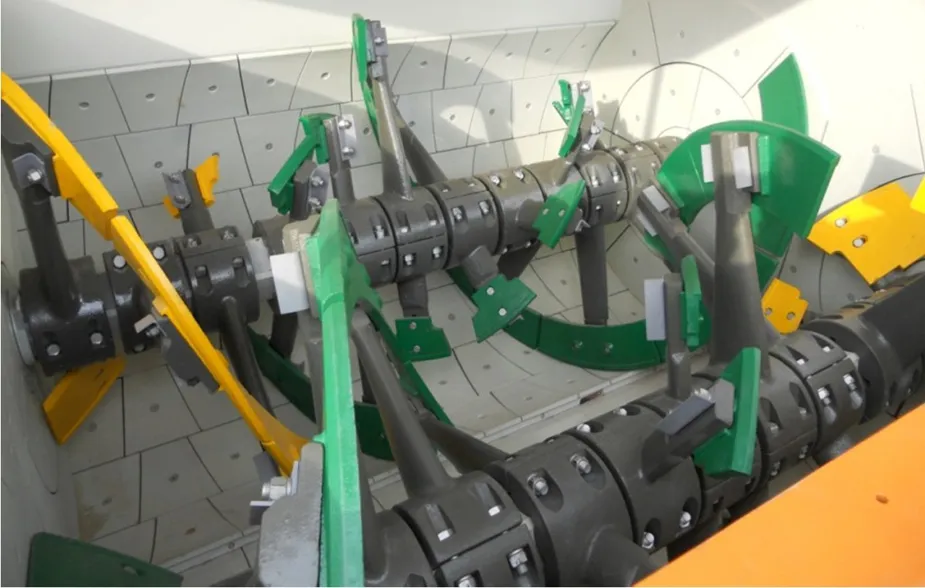

The design uses Elba’s productive and well-proven double spiral mixing system with an EMS or EMDW mixer. The different variants offer outputs of 105-200m3/hour while mixer sizes from the EMS 2000-2500 are available. The plant also continues with the same skip and belt elevation configuration that Elba has been using successfully for some time. The drive systems and the various safety features meanwhile comply with the latest standards and energy directives.

Designed to meet tough environmental requirements for some markets, a dust control system is fitted. Galvanised steel is used for key components to reduce corrosion and extend life while wide platforms optimise access and make maintenance easier and quicker. The plants are available with aggregate storage from 70 to 312m3 and can handle aggregate grades from 2 to 12.

Cement weighing connections are fitted while other options include additional feeds for additives or special products.

Plant configuration is important for quality and productivity and

Concrete producer Betonrossi is based in Pescantina in Italy and is using a highly sophisticated Cifamix 100 batching plant to help optimise product quality. The facility produces from 500 to 2,000m3/day when demand is at a peak and features a skip for loading aggregates into the mixer, four concrete silos, six aggregates bins and an aggregates feed system that uses a sloping belt and four underground hoppers. A wheeled loader handles the aggregates feed, which is then carried to the automated underground hoppers. The sloping belt moves the aggregates to the plant and the skip then raises this material and tips it into the mixer.

The mixing process for the aggregates, water and cement is controlled precisely from the cabin. Sophisticated controls are said to ensure a high-quality product that is then transported to the loading point where it is fed into the waiting truck mixers.

Betonrossi now has an extensive array of similar batching plants across its 40 or so sites in Northeast Italy, a significant percentage of which were supplied by Cifa. The customer opted for pre-mix type plants as it believes that this technology offers better product quality than a dry-mix system (although Cifa also offers the latter in its range).

Betonrossi has plants located in Piacenza, Treviso, Venice, Padua, Vicenza, Verona, Mantua, Brescia, Modena, Trento, Bolzano, Milan, Cremona, Lodi and Parma.

The modern Cifamix range offers production rates from 90 to 120 m3/hour and the firm claimed that the plants are compact and reliable, with high output while also meeting strict environmental requirements. The modular configuration allows a customer to select components according to a range of installation and production requirements. Customers can opt for a horizontal double axle mixer or a vertical axle type. Different aggregates bin layouts can be installed, with capacities from 100 to 300m3.

The structural components are hot-dip galvanised for long life and are pre-assembled and pre-wired to reduce the time needed for assembly and commissioning. Highly sophisticated automation technology is said to deliver product homogeneity and quality.

To further expand the range of options for the customer, MCT offers its plants in mobile versions that allow fast dismantling and re-installation on another site. A wide range of customer options are available from the firm, which can tailor the plant to meet demands imposed by the weather and climate, the specific location (such as in an urban area) and other more general production needs. Plant layout can be optimised to ensure efficient vehicle traffic and materials management. These plants feature wet-batch technology as well as the twin-shaft mixers. The plant can handle multiple batches simultaneously due to its Compumat software technology and its other advanced features. MCT claimed that this is a function of its novel double-batch technology. Output is said to be high and the 4.3m3 twin-shaft mixer plant can load an 8.6m capacity truck in less than four minutes.

Meanwhile, remote monitoring by trained staff is available from MCT's main factory in ltaly. Features available include an aggregates dosing system with inching valves for accurate flow control, aggregates weighing and conveying systems for dosing and transporting aggregates, and cement hoppers mounted on loadcells. They also include a hydraulic discharge gate to free the mixer for the next batch, integrated control systems for humidity and plasticity to ensure consistency and emissions controls solutions to minimise dust and improve efficiency. The emission controls include air displacement bags, dust control filters, hoods and special skirting. Customised solutions are available for reclaiming material that would otherwise go to waste, including separation screws with trough and receivers for returning concrete and filter-presses and other downstream treatments.

The primary works involved the installation of a new Rapid R3000 3m3 pan mixer contained within a new fully cladded mixer platform. Modifications included upgrades to the existing weighed belt, extension to conveyor from weighed belt to mixer platform, installation of a new aggregate holding hopper and Rapid’s very own high-pressure mixer washout system.

Additional features were also included to allow Ty-Rock to be flexible in producing a variety of products from their range. This included a movable wet-batch hopper. A ready-mix extension chute was also designed to allow better service for ready-mix collections.

Ty-Rock said that the upgrading of the plant has helped the firm to increase output and provide more efficient loading times.

The Rapid R3000 pan mixer is capable of producing output batches of 3m3 and is said to offer high outputs and fast discharge time. Features are said to include durable chill cast tiles, wear sleeves and paddles supplied as standard, as well as heavy-duty discharge door mechanisms. Spring-tensioned mixing arms are said to optimise safety while the mixer also has an uprated gearbox. In addition, Ty-Rock opted to have its new Rapid pan mixer fitted with a jetwash head, allowing for integration with a Rapid jetwash system for high-pressure mixer cleaning.

The plant typically features three horizontal bins offering a total capacity of 55m³, the twin-shaft MDC 500 continuous mixer, a mixer trestle, a concrete holding hopper system and a cabin equipped with the sophisticated FLOWMATIC control system.

Other features include dosing systems with a weighing hopper for cement and a magnetic flowmeter for water, as well as a dual concrete feeding system with reversible belt for concrete discharge and concrete product hoppers with capacities from 4 to 15m3. The firm said that a customer in Brazil recently took delivery of a highly versatile plant, which was equipped with four horizontal bins offering a total capacity of 40m³, an MDC 500 twin-shaft continuous mixer and a mixer supporting frame. This plant was designed to mix up to 600tonnes/hour and is equipped with the FLOWMATIC control system to optimise product quality. The sophisticated FLOWMATIC system logs all production data and this allows the producer to replicate the same concrete mix easily for future jobs if required.