Over the past two years, construction company

The normal percentage of RAP in Sweden’s surface layers is up to 20%. Enabling 70% RAP content was the use of the bio-based RAP rejuvenator called Sylvaroad RP1000 Performance Additive, made by

“Based on extensive testing and analysis, we were confident that it would restore the properties of the aged binder to those of virgin material,” explains Bruno Vuillier, market development manager at Kraton. “After a year of use, Road 694 is holding up well to the nearly 3,000 vehicles that travel on it daily.”

Skanska, which has experimented with several rejuvenators, began laboratory and road tests of Sylvaroad RP1000 in 2013. “It’s of foremost importance that every road we pave meets our short- and long-term performance requirements,” says Kenneth Olsson, specialist for asphalt and bitumen at Skanska. “One of the key findings that influenced our decision to use Sylvaroad RP1000 was the excellent workability of the mixture, even when using high percentages of RAP.”

Enabling this effective performance is Sylvaroad’s RP1000’s ability to activate and mobilise old binder so it is reinvigorated at the molecular level, rather than simply diluting the material as do many petroleum-based additives. A substantial challenge faced by road construction professionals occurs when attempting to use RAP in higher value applications, such as the critical surface layer. Traditionally, asphalt mixes with more than 30% RAP tend to be too stiff, resulting in premature failures, often in the form of cold weather cracking.

In 2014, Skanska prepared to assess over time the binder’s low-temperature performance. The company paved a surface layer with a mix of 80% RAP enabled by Sylvaroad RP1000. Skanska also took a core sample from the surface layer of a road with no RAP in the mix.

In 2015, after one year in service for the road with 80% RAP, the binder was tested and compared to the 0% RAP binder of the core sample. The results (see table 1) show that the binder performance of an 80% RAP asphalt mix with Sylvaroad RP1000 was comparable to the one of an asphalt mix composed of only virgin material.

| Low temperature Property (degrees celcius) | Surface Asphalt Mix (0% RAP) | Surface Asphalt Mix (80% RAP & 5.5%* Sylvaroad RP1000) |

|---|---|---|

| Fraass Breaking Point | -15 | -15 |

| BBR - Temperature for 300MPa stiffness | -18.9 | -18.9 |

| BBR - Temperature for 0.300 m-value | -15.1 | -19.3 |

| BBR - Low temperature criteria (superpave performance grading) | -15.1 | -18.9 |

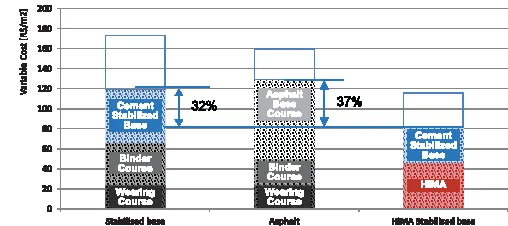

Still, it’s important at the same time to maintain - or even improve - the performance of the binder at intermediate temperature for the fatigue behaviour and at high temperature for rutting resistance behaviour. Results after one year of service (see charts) show that intermediate-to-low temperature behaviour was reinstated and high temperature performance was not compromised. The surface is expected to have better rutting resistance behaviour than the reference 0% RAP.

“We believe there is tremendous potential for rejuvenators such as Sylvaroad RP1000 to be used with high percentages of RAP in wearing courses. We’re working toward the day when it’s the norm for mixes to contain 50-100% RAP in some of our paved surface layers.”

In October 2017, a section of Sweden’s southwest E20 Motorway near Hova was paved with 30% RAP in its binder layer and 50% on its base layer, percentages enabled by Sylvaroad RP1000. To compare road durability on this project, Skanska laid out another section of road with the same amounts of RAP. This section used soft bitumen 330/430 for blending to the right penetration grade in the layers. Skanska’s asphalt plant in Lidköping produced the mixes with a parallel drum for heating up the RAP.

With heavy vehicles comprising around 25% of traffic on the E20, Skanska will regularly monitor the road’s performance regarding fatigue, deformation and other issues.

Advancing sustainability

Projects that use increased amounts of RAP enabled by Sylvaroad RP1000 in all road layers are an integral part of Skanska’s comprehensive sustainability efforts. This includes Skanska Sweden becoming carbon neutral in the entire value chain by 2050. Sylvaroad RP1000 enables the use of greater quantities of older asphalt which minimises asphalt disposal and reduces the need to manufacture large amounts of virgin asphalt.

“Working to reduce carbon dioxide emissions will use less material, increase and reduce energy and waste. This will also reduce costs,” says Agneta Wannerström, senior manager for carbon neutrality at Skanska Sweden. “The ability to use greater amounts of reclaimed asphalt and a wood-based additive for our road projects – and achieve the performance requirements we demand – goes a long way toward helping us reach those targets.”

The environmental benefits of this new approach to road construction are three-fold. The rejuvenator is made from bio-based pine chemicals derived from the wood industry. Increased amounts of RAP allow for more effective asphalt recycling and minimisation of virgin petroleum binder and aggregate production. All this ultimately decreases the amount of greenhouse gas in the environment.

“For Kraton, Sylvaroad RP1000 represents the company’s dedication to developing innovative, bio-based products that provide optimal value to our customers,” says Vuillier.