A new Scottish specification for stone mastic asphalt could help with some of the durability issues sometimes experienced in the UK

An alternative specification for stone mastic asphalt has been used on the A90 in Scotland, with tests suggesting that the material will be more durable than thin surfacing produced under the standard UK specification, Clause 942 of the Specification for Highway works.

May 20, 2014

Read time: 3 mins

A new Scottish specification for stone mastic asphalt could help with some of the durability issues sometimes experienced in the UK

An alternative specification for stone mastic asphalt has been used on the A90 in Scotland, with tests suggesting that the material will be more durable than thin surfacing produced under the standard UK specification, Clause 942 of the Specification for Highway works.

The Scottish specification, TS 2010 (soon to be renamed Clause 942TS), is much more prescriptive than the English system and specifies a polymer modified binder, a grading and binder envelope and an air void content of the finished product. It also specifies thickness requirements, the use of fibre, resistance to deformation and early life skid resistance as measured by a GRIP tester. Each quarry requires a separate approval for each mix type.

“Bearing in mind the higher binder contents specified and the void content required, this type of product must be more durable than a standard clause 942 material. I believe many failures of thin surfacing are directly attributable to high voids and low binders,” said Neil Anderson, technical director of Leiths Group which supplied and laid the material.

“Given that exactly the same plant and labour resources are used to manufacture and lay a clause 942 material compared with a TS 2010 material, the case for following the TS 2010 specification and producing a more durable material are compelling.”

The contract – for resurfacing the A90 trunk road near Aberdeen – called for a clause 942 thin surfacing using a polymer modified binder and 10mm aggregate laid 30mm thick along a 2.5km stretch of road. Aggregates had to have a minimum polished stone value of 55, a maximum AAV of 14 and a flakiness index of FI 20. Wheel tracking level 3 and road/tyre noise level 1 were specified along EME2 support layers for the surfacing, and a performance guarantee of five years.

“Two sections of the new construction required a higher PSV of 68 – however, higher PSV aggregates tend to be less durable than lower PSV mixes when used as thin surfacing,” said Anderson.

Leiths offered an alternative, a material that would meet all of the contract requirements Plus also meet TS 2010. “It was decided to proceed with two SMA mixes, a 10mm and a 6mm using local granite aggregates of PSV56, laid to a target thickness of 35mm,” Anderson says. For the polymer modified bitumen Leiths used294 Nynas Nypol 103, a highly modified elastomeric binder which demonstrates substantial resistance to deformation and cracking.

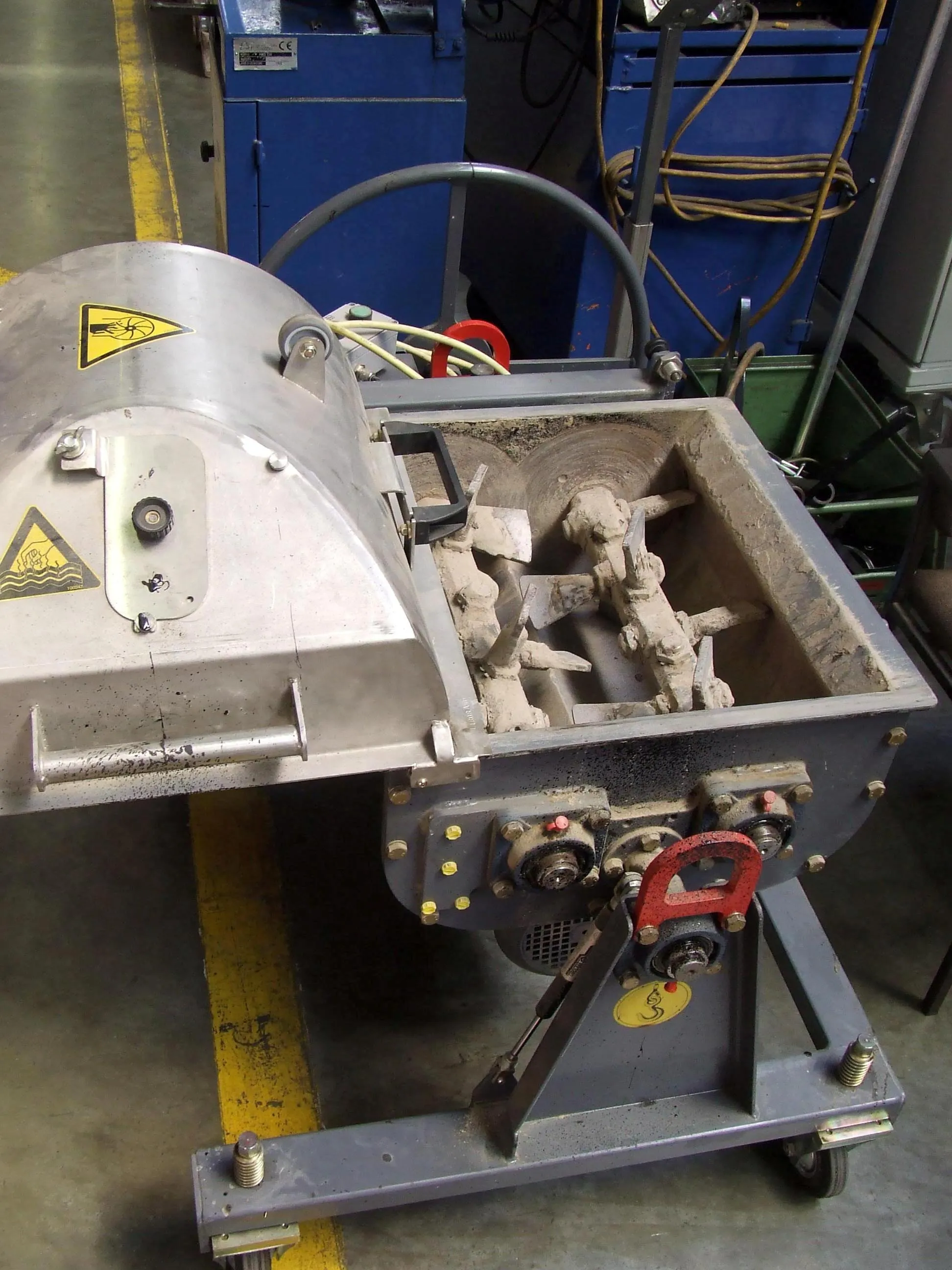

To comply with TS2010, two stages of trials were required as part of the approval process, involving laboratory mix designs and production and laying trials. Deemed satisfactory, the material was laid on the A90 for a trunk road network trial.

Extensive tests of the laid material included taking nuclear density gauge readings every 20m in alternative wheel tracks to check in situ density compliance. Voids were found to comply with the specification. A GRIP test was carried out immediately the contract was completed and values greater than 0.7 (0.62 Scrim) were achieved. This was a greater skid resistance than required by the contract, and higher than the 0.55 Scrim level required for a Class 3 site.

On the A90 project, 6mm SMA was laid in the areas of the junctions where a greater degree of skidding resistance was required. A PSV test of the aggregate fraction used in this layer gave results of 73. The early life skid resistance values of the 6mm surfacing proved marginally higher than the 10mm surfacing made with the same aggregate type.

An alternative specification for stone mastic asphalt has been used on the A90 in Scotland, with tests suggesting that the material will be more durable than thin surfacing produced under the standard UK specification, Clause 942 of the Specification for Highway works.

The Scottish specification, TS 2010 (soon to be renamed Clause 942TS), is much more prescriptive than the English system and specifies a polymer modified binder, a grading and binder envelope and an air void content of the finished product. It also specifies thickness requirements, the use of fibre, resistance to deformation and early life skid resistance as measured by a GRIP tester. Each quarry requires a separate approval for each mix type.

“Bearing in mind the higher binder contents specified and the void content required, this type of product must be more durable than a standard clause 942 material. I believe many failures of thin surfacing are directly attributable to high voids and low binders,” said Neil Anderson, technical director of Leiths Group which supplied and laid the material.

“Given that exactly the same plant and labour resources are used to manufacture and lay a clause 942 material compared with a TS 2010 material, the case for following the TS 2010 specification and producing a more durable material are compelling.”

The contract – for resurfacing the A90 trunk road near Aberdeen – called for a clause 942 thin surfacing using a polymer modified binder and 10mm aggregate laid 30mm thick along a 2.5km stretch of road. Aggregates had to have a minimum polished stone value of 55, a maximum AAV of 14 and a flakiness index of FI 20. Wheel tracking level 3 and road/tyre noise level 1 were specified along EME2 support layers for the surfacing, and a performance guarantee of five years.

“Two sections of the new construction required a higher PSV of 68 – however, higher PSV aggregates tend to be less durable than lower PSV mixes when used as thin surfacing,” said Anderson.

Leiths offered an alternative, a material that would meet all of the contract requirements Plus also meet TS 2010. “It was decided to proceed with two SMA mixes, a 10mm and a 6mm using local granite aggregates of PSV56, laid to a target thickness of 35mm,” Anderson says. For the polymer modified bitumen Leiths used

To comply with TS2010, two stages of trials were required as part of the approval process, involving laboratory mix designs and production and laying trials. Deemed satisfactory, the material was laid on the A90 for a trunk road network trial.

Extensive tests of the laid material included taking nuclear density gauge readings every 20m in alternative wheel tracks to check in situ density compliance. Voids were found to comply with the specification. A GRIP test was carried out immediately the contract was completed and values greater than 0.7 (0.62 Scrim) were achieved. This was a greater skid resistance than required by the contract, and higher than the 0.55 Scrim level required for a Class 3 site.

On the A90 project, 6mm SMA was laid in the areas of the junctions where a greater degree of skidding resistance was required. A PSV test of the aggregate fraction used in this layer gave results of 73. The early life skid resistance values of the 6mm surfacing proved marginally higher than the 10mm surfacing made with the same aggregate type.