With the introduction of EU regulations in 2012 controlling the disposal of dry and wet waste from road sweepings and gully waste and it is not acceptable to send this material to landfill. Many local authorities have had to find an alternative solution.

R&W Civil Engineering in the southern UK country of Hampshire, is a specialist in highway construction, maintenance and other transport related services. It, along with other contractors started transporting waste material to the nearest processing stati

January 15, 2016

Read time: 2 mins

RSSWith the introduction of EU regulations in 2012 controlling the disposal of dry and wet waste from road sweepings and gully waste, it is not acceptable to send this material to landfill. Many local authorities have had to find an alternative solution

R&W Civil Engineering in the southern UK county of Hampshire, is a specialist in highway construction, maintenance and other transport-related services. Along with other contractors, it started transporting waste material to the nearest processing station in Dartford, in the county of Kent, far to the east.

This was not, however, the best environmentally friendly approach, resulting in short working shifts, long night journeys and reduced productivity.

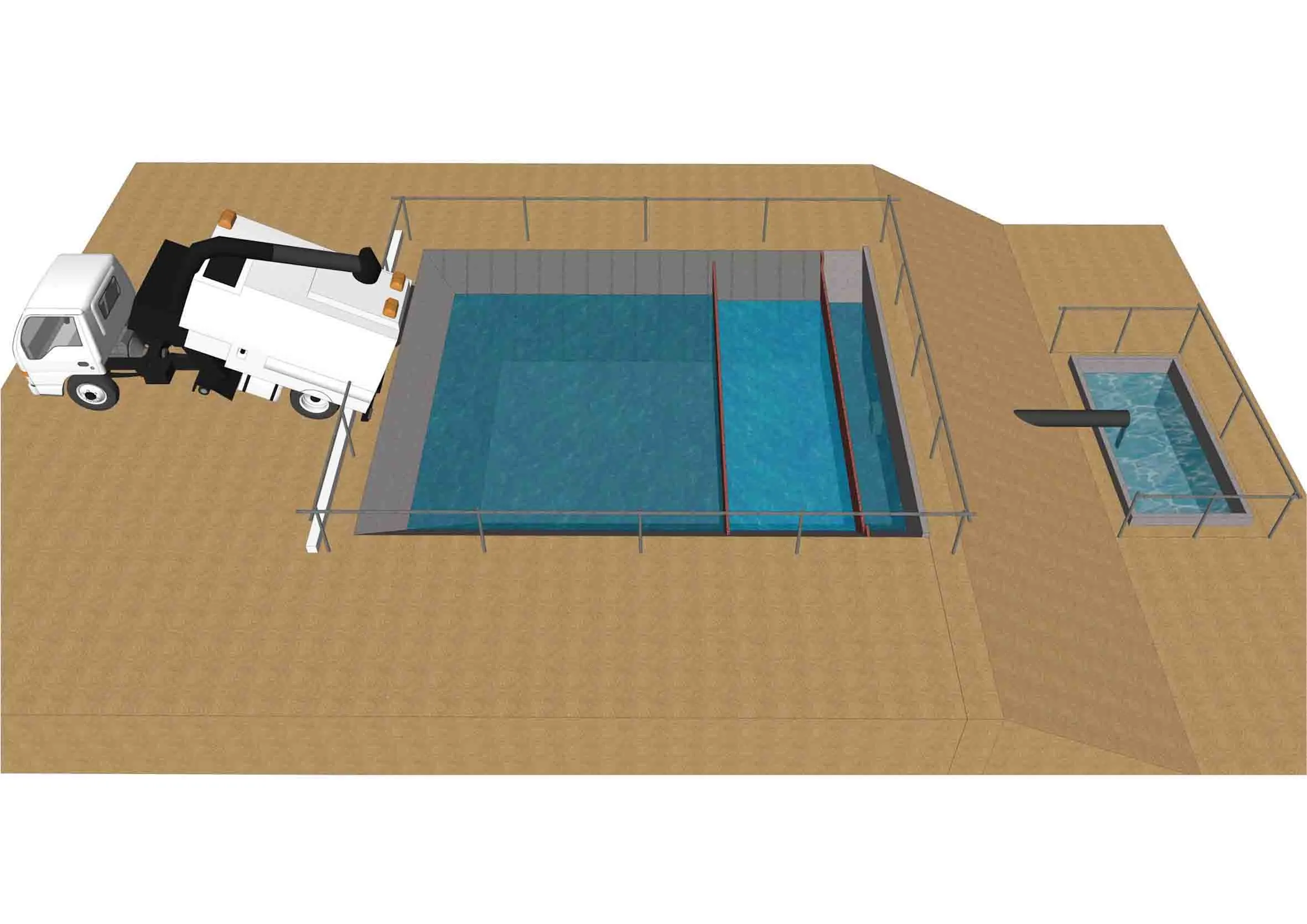

High volumes of contaminated water within the waste matter needed to be disposed of but the proposed treatment plant site had no foul sewer connection. The project developed an effective water management and purification strategy in order to solve a greater recycling issue: How to process wet waste, road sweepings and gully waste without a foul sewer connection.

R&W proposed to build - at its own expense - a wet-waste transfer and recycling station on its own engineering and logistics facility at Hursley, a town in Hampshire, to service the county, assuming it could then manage the contract.

The new plant now enables contractors - supporting national road network operations throughout Area 3, Hampshire County Council - R&W trucks and others to deliver waste to the facility for processing locally.

The 10% that still goes to landfill is mostly unrecyclable or unusable solids and general rubbish. Water is purified to river-quality and reused by gully trucks for jetting highway drainage systems.

Recoverable materials are removed and what remains is processed to produce a BS3882-compliant general purpose topsoil. This is used on a wide range of civil engineering schemes across the local8100 Highways England network area and other non-trunk route networks throughout the region.

Now the project diverts 1.5 million litres of mains drinking water from use on the highways. R&W said that if each county in the UK adopted this approach it would equate to 80 million litres or 320,000 Olympic-sized swimming pools of drinking water saved annually. RSS

R&W Civil Engineering in the southern UK county of Hampshire, is a specialist in highway construction, maintenance and other transport-related services. Along with other contractors, it started transporting waste material to the nearest processing station in Dartford, in the county of Kent, far to the east.

This was not, however, the best environmentally friendly approach, resulting in short working shifts, long night journeys and reduced productivity.

High volumes of contaminated water within the waste matter needed to be disposed of but the proposed treatment plant site had no foul sewer connection. The project developed an effective water management and purification strategy in order to solve a greater recycling issue: How to process wet waste, road sweepings and gully waste without a foul sewer connection.

R&W proposed to build - at its own expense - a wet-waste transfer and recycling station on its own engineering and logistics facility at Hursley, a town in Hampshire, to service the county, assuming it could then manage the contract.

The new plant now enables contractors - supporting national road network operations throughout Area 3, Hampshire County Council - R&W trucks and others to deliver waste to the facility for processing locally.

The 10% that still goes to landfill is mostly unrecyclable or unusable solids and general rubbish. Water is purified to river-quality and reused by gully trucks for jetting highway drainage systems.

Recoverable materials are removed and what remains is processed to produce a BS3882-compliant general purpose topsoil. This is used on a wide range of civil engineering schemes across the local

Now the project diverts 1.5 million litres of mains drinking water from use on the highways. R&W said that if each county in the UK adopted this approach it would equate to 80 million litres or 320,000 Olympic-sized swimming pools of drinking water saved annually. RSS