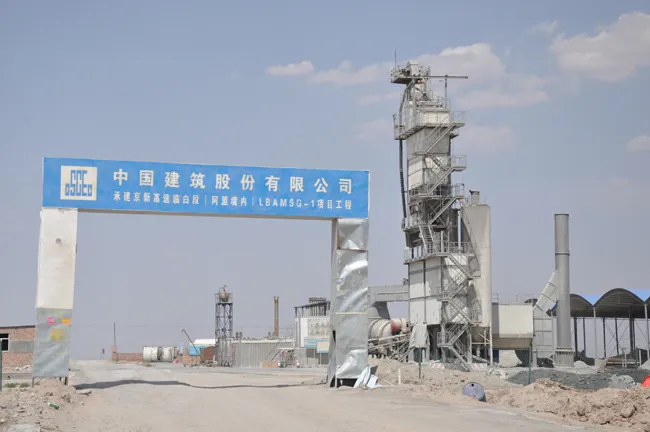

CSCEC Road & Bridge is a highly successful business in China and utilises

However, production output is not the only key factor for asphalt plants in China. New regulations are requiring an increasing use of ARP in asphalt mixes, so as to improve the environmental profile of construction operations.

“In recent years, as more and more public-private partnerships are coming out, we also are paying more attention to recycling technology,” said Zhou Shixin, chairman of a CSCEC Road & Bridge branch in Shijiazhuang City.

The company has owned four productive Ammann Uniglobe plants for some time but these machines are still well within their effective operating life and have many years of productive use ahead of them before requiring replacement. As a result CSCEC Road & Bridge opted to add recycling capabilities to its existing Ammann plants

Ammann has considerable expertise in upgrading its plants. The upgrade for the four plants has included the addition of an RAH drum that heats the RAP before depositing it in the mixer. When using RAP in a mix it is necessary to have the separate RAH drum because the material has to be gently preheated.. This is because the valuable bitumen in the RAP can be damaged when overheated. After preheating, the RAP is deposited in the mixer, where it is then blended with the hot virgin aggregate. The result is a quality mix with a high percentage of recyclables.

Ammann has a great deal of experience in making the plant upgrades, and was able to complete the work in the off-season, so as not to affect the firm’s production during its busy period.

Adding the RAP capability has proven effective for the customer as this method is considerably less expensive than purchasing a new plant with recycling ability. According to Zhou, this has provided a highly cost-effective solution.

The company appreciates the green approach and the costs savings. “We can mill our own material for public-private partnerships and reduce costs by 20-30%,” Zhou said.