Driven by the price of virgin aggregates and strong environmental concerns, the recycling of reclaimed asphalt already is and will increasingly be a hot topic within the asphalt plants’ and associated equipment manufacturing sector, says Kathrin Richter, marketing manager for Ammann’s Asphalt Division “Until a few years ago, the question was: How much reclaimed asphalt can one add to the recipe mix? Today, the question is more likely to be: How much fresh material should I add to the reclaimed asphalt? Ove

May 20, 2014

Read time: 4 mins

Driven by the price of virgin aggregates and strong environmental concerns, the recycling of reclaimed asphalt already is and will increasingly be a hot topic within the asphalt plants’ and associated equipment manufacturing sector, says Kathrin Richter, marketing manager for 6791 Ammann’s Asphalt Division

“Until a few years ago, the question was: How much reclaimed asphalt can one add to the recipe mix? Today, the question is more likely to be: How much fresh material should I add to the reclaimed asphalt? Over the past ten years, the subject of recycling reclaimed asphalt has gained ever greater importance wherever road maintenance is a major issue. The future of road construction therefore lies in real asphalt recycling.

A world road map of today shows two huge and largely well-developed road networks: that of the USA and that of ‘old’ Europe – each of which is around seven million kilometres long. Nonetheless, the asphalt required for road maintenance will far exceed the quantities required for new road construction projects. The number of new roads being built in Western Europe is already in decline. The asphalt produced is therefore mainly used for refurbishment measures and extending the capacity of the existing road network. These measures result in millions of tonnes of reclaimed asphalt (RA) that are virtually all recycled to produce new asphalt for the roads.

Asphalt is one of the few materials that can be 100 % recycled, and it is also one of the most commonly produced materials at around 1.6 billion tonnes/year. Whilst other materials lose value every time they are recycled, asphalt can be reused for its original intended purpose a number of times. Asphalt used in road construction therefore enables a closed material loop. Over the past decades, builders, research and development engineers and the road construction industry in Germany and other countries have continuously striven towards achieving a higher recycling rate. As asphalt consists largely of local aggregate and bitumen derived from oil, recycling asphalt represents an important contribution towards the preservation of resources. This goes hand in hand with a reduction in the use of so-called ‘grey energy’ that would otherwise be consumed for the production, storage and transport of primary base materials.

Real recycling means that the asphalt reclaimed from the old road is reused to build new, high-quality layers of asphalt. The idea, therefore, is to use as much reclaimed asphalt as possible in conjunction with corrective grain, fresh binder and additives to produce high-quality asphalt. The technical prerequisites for a closed-loop material cycle for reclaimed asphalt are fulfilled and the use of RA material will increase further still in the future. However, the use of reclaimed asphalt also places high demands on asphalt producers and their production plants. Heating reclaimed asphalt gently is of decisive importance in this process. The bitumen in the asphalt is subject to an ongoing ageing process during production and the time it spends in the road surface.

What this basically means is that the bitumen becomes more viscous, rigid and brittle. The effects of the ageing process can be significantly reduced by applying suitable conditioning methods or using special additives. Asphalt producers can make use of various methods and technologies depending on the target proportion of reclaimed asphalt.

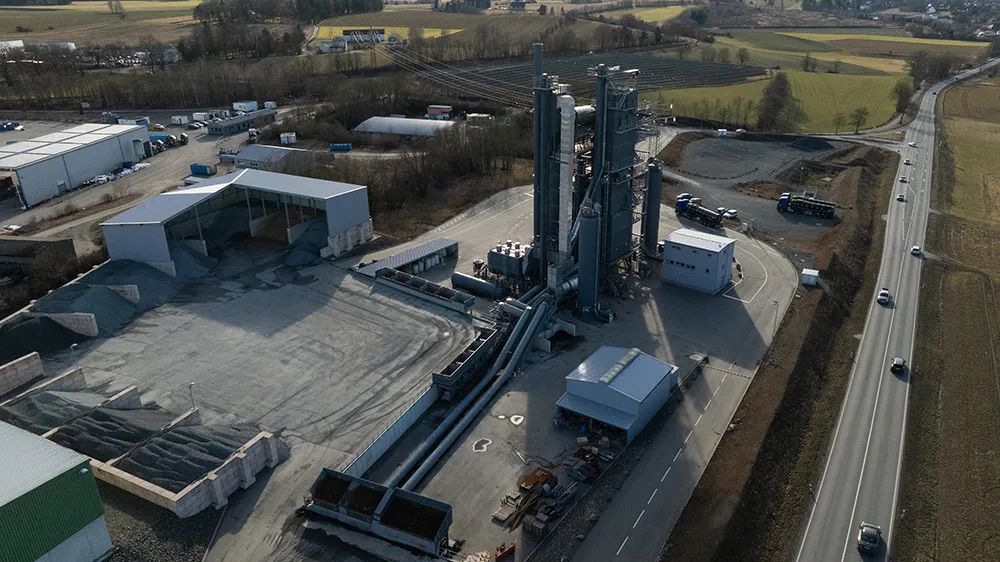

A paradigm shift in recent years has promoted reclaimed asphalt from a supporting role to the main actor and therefore to the decisive component in the mix. The Universal HRT (High Recycling Technology) mixing plant from Ammann is designed specifically for using very high proportions of reclaimed asphalt and reflects the fundamental change in the philosophy of asphalt production. The most striking difference to conventional asphalt mixing plants is that the entire recycling household is arranged vertically above the mixer to guarantee minimum wear and optimum transportation of the hot reclaimed asphalt. The HRT approach also means that there is enough room in the plant’s tower for additive feed components as well as for carrying out inspection and maintenance work, and that the entire production process is monitored by the control system. The state-of-the-art HRT technology was convincing right from the start. A number of these plants – some of them equipped with the 100 % RA system – have been sold in Europe since the start of last year’s Bauma in Munich.

The ’High Recycling Technology’ is a new philosophy in asphalt conditioning that reflects the latest environmental developments with regard to preserving resources. This new concept supports sustainable road construction.

“Until a few years ago, the question was: How much reclaimed asphalt can one add to the recipe mix? Today, the question is more likely to be: How much fresh material should I add to the reclaimed asphalt? Over the past ten years, the subject of recycling reclaimed asphalt has gained ever greater importance wherever road maintenance is a major issue. The future of road construction therefore lies in real asphalt recycling.

A world road map of today shows two huge and largely well-developed road networks: that of the USA and that of ‘old’ Europe – each of which is around seven million kilometres long. Nonetheless, the asphalt required for road maintenance will far exceed the quantities required for new road construction projects. The number of new roads being built in Western Europe is already in decline. The asphalt produced is therefore mainly used for refurbishment measures and extending the capacity of the existing road network. These measures result in millions of tonnes of reclaimed asphalt (RA) that are virtually all recycled to produce new asphalt for the roads.

Asphalt is one of the few materials that can be 100 % recycled, and it is also one of the most commonly produced materials at around 1.6 billion tonnes/year. Whilst other materials lose value every time they are recycled, asphalt can be reused for its original intended purpose a number of times. Asphalt used in road construction therefore enables a closed material loop. Over the past decades, builders, research and development engineers and the road construction industry in Germany and other countries have continuously striven towards achieving a higher recycling rate. As asphalt consists largely of local aggregate and bitumen derived from oil, recycling asphalt represents an important contribution towards the preservation of resources. This goes hand in hand with a reduction in the use of so-called ‘grey energy’ that would otherwise be consumed for the production, storage and transport of primary base materials.

Real recycling means that the asphalt reclaimed from the old road is reused to build new, high-quality layers of asphalt. The idea, therefore, is to use as much reclaimed asphalt as possible in conjunction with corrective grain, fresh binder and additives to produce high-quality asphalt. The technical prerequisites for a closed-loop material cycle for reclaimed asphalt are fulfilled and the use of RA material will increase further still in the future. However, the use of reclaimed asphalt also places high demands on asphalt producers and their production plants. Heating reclaimed asphalt gently is of decisive importance in this process. The bitumen in the asphalt is subject to an ongoing ageing process during production and the time it spends in the road surface.

What this basically means is that the bitumen becomes more viscous, rigid and brittle. The effects of the ageing process can be significantly reduced by applying suitable conditioning methods or using special additives. Asphalt producers can make use of various methods and technologies depending on the target proportion of reclaimed asphalt.

A paradigm shift in recent years has promoted reclaimed asphalt from a supporting role to the main actor and therefore to the decisive component in the mix. The Universal HRT (High Recycling Technology) mixing plant from Ammann is designed specifically for using very high proportions of reclaimed asphalt and reflects the fundamental change in the philosophy of asphalt production. The most striking difference to conventional asphalt mixing plants is that the entire recycling household is arranged vertically above the mixer to guarantee minimum wear and optimum transportation of the hot reclaimed asphalt. The HRT approach also means that there is enough room in the plant’s tower for additive feed components as well as for carrying out inspection and maintenance work, and that the entire production process is monitored by the control system. The state-of-the-art HRT technology was convincing right from the start. A number of these plants – some of them equipped with the 100 % RA system – have been sold in Europe since the start of last year’s Bauma in Munich.

The ’High Recycling Technology’ is a new philosophy in asphalt conditioning that reflects the latest environmental developments with regard to preserving resources. This new concept supports sustainable road construction.