The firm is utilising an

Alex Fraser Group has opened a state-of-the-art glass recycling plant in the state of Victoria that is being used to process glass waste and turn it into a high-quality sand. Processed glass waste is turned into sand, which is then used by the adjacent Ammann ABP HRT plant to produce asphalt. In addition to supplying the Ammann plant, the recycling facility provides road base, aggregates and sand for green road and rail projects.

The plant can recycle up to 4 million bottles and produce up to 800tonnes of high-specification sand/day. According to the company, the source materials come from “problematic glass waste streams that were previously stockpiled or landfilled.

“Our new glass recycling plant is capable of producing 200,000tonnes of recycled glass sand/year – equivalent to a billion bottles, effectively putting an end to glass waste stockpiles and landfill in Victoria,” said Peter Murphy, managing director for Alex Fraser.

The Ammann ABP HRT asphalt plant is designed to incorporate recycled asphalt pavement (RAP) and other recyclable products as the main stream materials that can produce more than 500,000tonnes of asphalt/year. It includes Ammann’s proprietary as1 EcoView control system software, which monitors energy consumption and emissions; a foaming system for warm-mix capability; and hot asphalt storage up to 72 hours.

“The Ammann plant complements the other aspects of the Alex Fraser business in regard to recycling,” said Paul Vandersluis, Managing Director of Ammann Australia. “Not only is the Ammann plant equipped with technology for today, but it can also accommodate future introductions of other types of recyclable materials – be it filler, binder or aggregate substitutes.”

“This energy-efficient plant is capable of producing high-quality asphalt mixes, made almost entirely of recycled materials,” Murphy said. “Our greenest asphalt mixes, like Glassphalt, which includes recycled glass, and PolyPave, which includes recycled plastics, are being produced here to supply a multitude of projects.”

This use of the waste glass addresses a problem in Victoria State, which also be applied elsewhere. The large quantities of problem glass waste, known as CSP, have previously had to be taken to landfill, at high cost. Made up of fine particles of glass co-mingled with other waste (including paper, plastics, metals and organics) this waste stream cannot be traditionally recycled back into the production of bottles or jars.

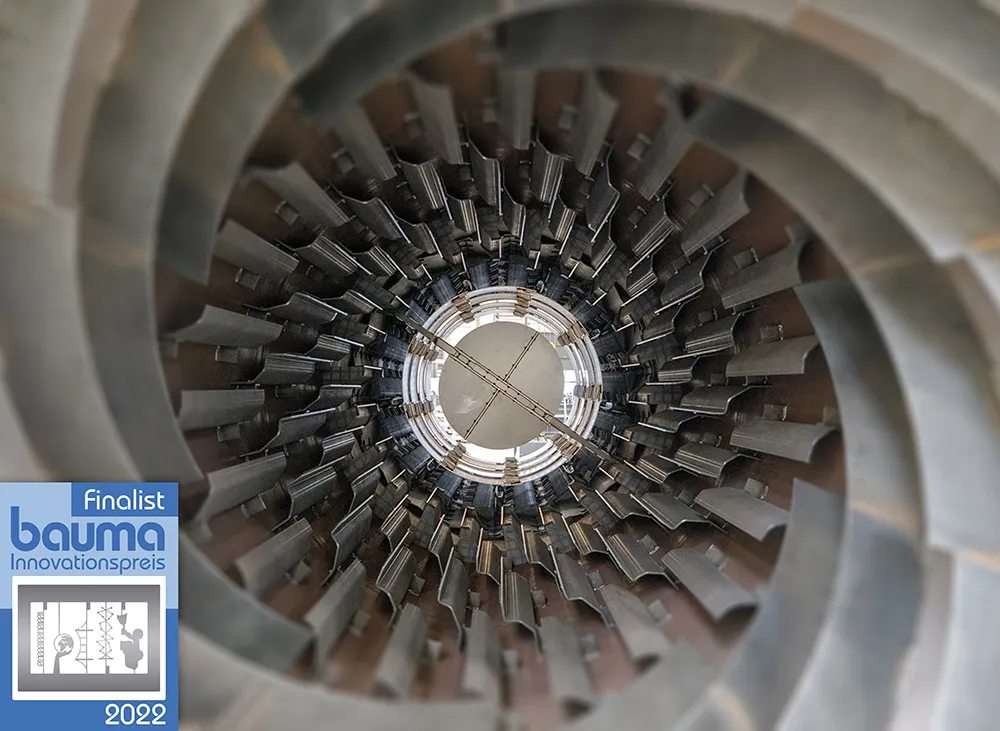

Murphy said the company combined years of recycling experience with the latest technology from around the world to design this innovative glass recycling plant. The new set-up uses a range of technologies to produce high-quality construction sand from the waste materials.

“Our new glass recycling plant separates the glass from the impurities and processes it into recycled sand, which complies with

The environmental benefit for the Australian state of Victoria is substantial. “The use of this material will have significant commercial and environmental savings, including the reduction of glass as landfill, vehicle movements, and the carbon footprint of new projects, by up to 65%,” Murphy said.