The Benninghoven RPP 4000 plant is being used to supply material for the new highway section of the E39 between Mandal East and Kristiansand West. Velde Produksjon opted to purchase an innovative RPP 4000 asphalt mixing plant, which met with the firm’s need for equipment able to deliver high recycling rates combined with low emissions. The use of this green technology has been supported by the state agency Enova in the form of a grant. Enova supports companies that opt to use innovative, climate-friendly technologies.

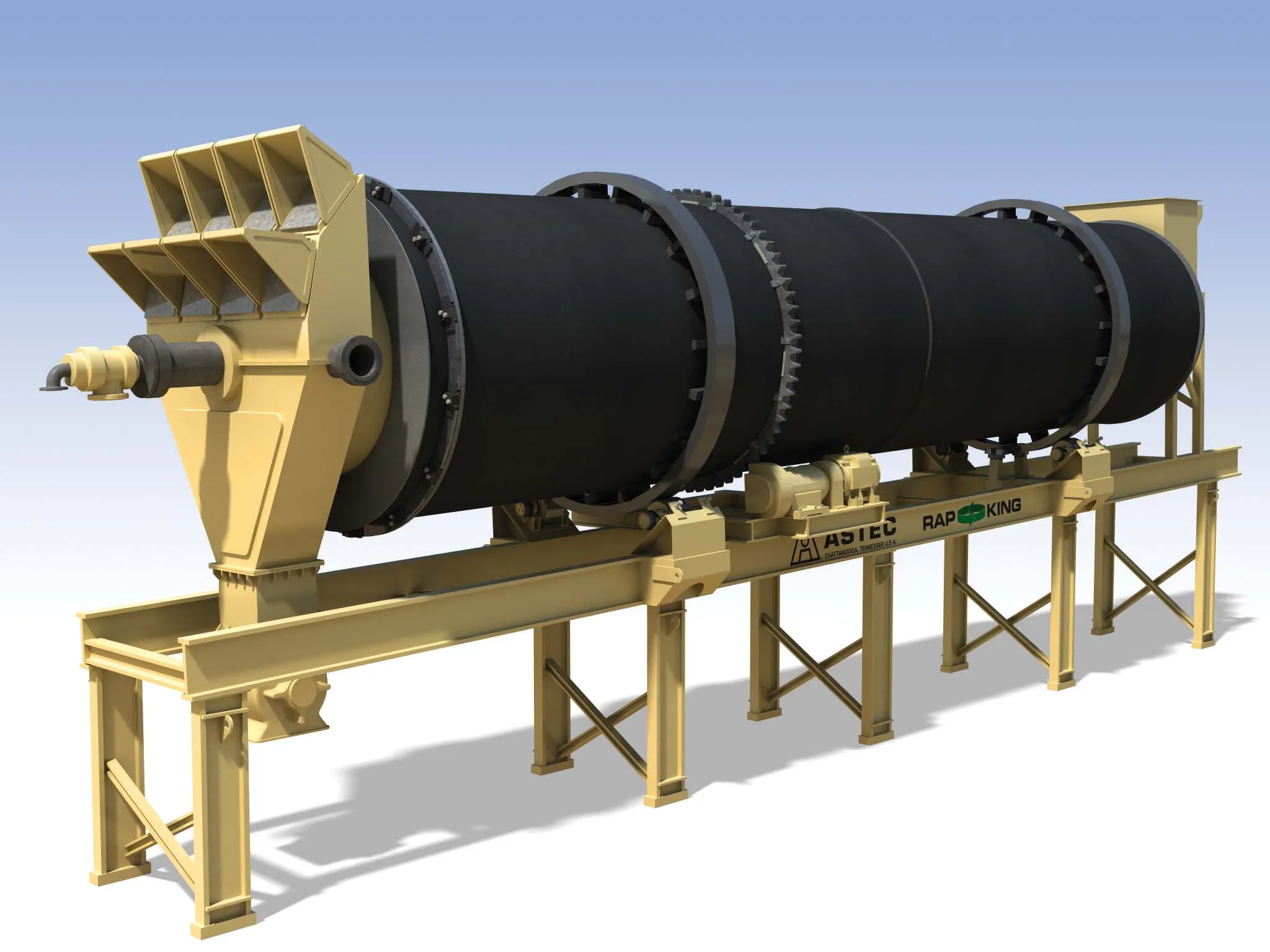

The highway section between Mandal and Kristiansand is part of a gigantic construction project for better access to the west coast of Norway. The new Benninghoven RPP 4000 plant is located directly at the Mandal Fjord in Brennevinsmyra and has its own jetty. This modern asphalt mixing plant has been in operation since August 2021. Equipped with a recycling drum with a hot-gas generator using counterflow action, it allows for up to 100% recycling material to be added while complying with the standard emission limits.

“With innovation, curiosity and investments in modern technologies, Velde will ensure the most efficient and environmentally friendly production possible,” said Egil Velde, CEO Velde Industri.

The relationship between Velde and Benninghoven goes back as far as 2005. Velde has evolved from a medium-sized company into Norway’s second largest mixing plant owner. The installation of a Benninghoven plant at the firm’s Sandnes quarry provided a way into asphalt production, and only a short time later the company decided to purchase a second plant. In February 2019, Velde took over an existing asphalt mixing plant in Agder county, well positioned for the Mandal–Kristiansand road job. This plant was too small though, so the firm decided to replace it with a larger unit, opting for the new Benninghoven plant in the same location.

Velde has set itself the goal of reducing the carbon footprint of asphalt production with innovative technology and decided that the RPP concept met its needs. Due to the detailed technical description from Benninghoven, Velde was able to secure the support from Enova.

The Enova state agency was founded in 2001 with the aim of driving the transition to more environmentally friendly consumption and sustainable production in the energy sector. The company has been affiliated with the Department for Climate And the Environment since 2018.

The plant has a number of special features including a loading silo for stocking large quantities of material, a recycling drum that uses counterflow action with a hot-gas generator and housing for all hoppers. It also offers the option for cold recycling with a multi-variable feed, has a dust collection system that meets new emissions requirements, has low operating costs and low Ctot emissions compared to conventional systems. In addition, the plant features a wood dust burner and a production capacity of 320tonnes/hour.

Due to the tight schedule for the motorway job, Velde was under time pressure and needed the plant installed quickly. It took less than a year until the new plant was commissioned in August 2021, despite COVID-19 rules on quarantine and immigration restrictions, as well as the tough winter weather conditions.