Marini has been involved for some years in supplying asphalt plants to Indian companies involved in road and airport construction programmes.

February 13, 2012

Read time: 3 mins

Through Marini India, the

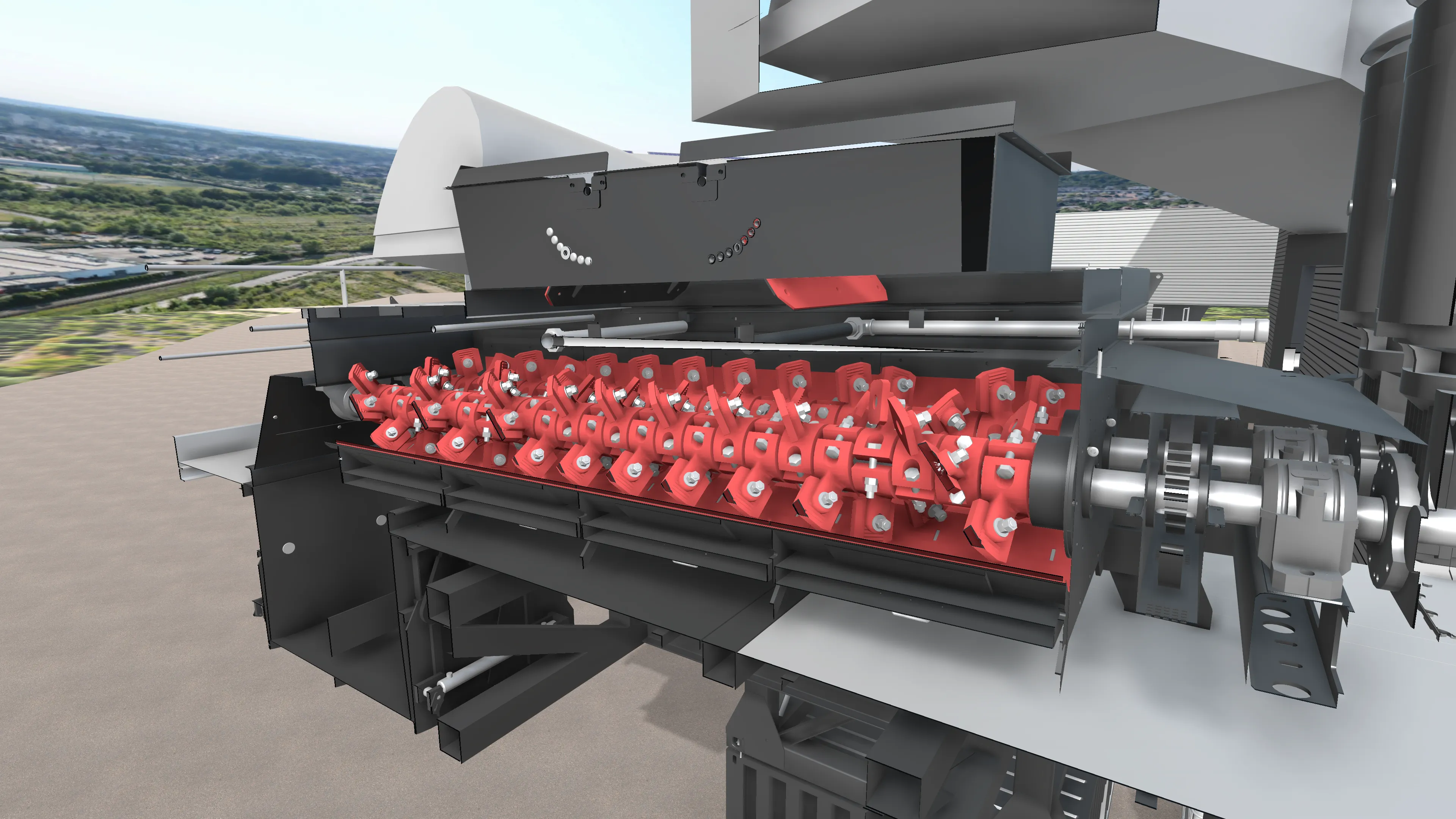

Marini says that its new generation of energy-efficient asphalt plants has been developed to meet customers' demands for versatility, quality and environmentally-friendly requirements.

The first Marini MAC commissioned by a team of engineers from Marini India produced around 1,200tonnes of high quality mix on day one and is now moving to another project site.

"No foundations, modular designs, zero ducts and minimal interfaces, ensured that the plant was put in to operation in a very short time," says Marini.

To minimise energy consumption at all process stages, the MAC uses a combination of innovative design along with waste heat recovery system. The dryer and blue flame-assisted burner design is said to "offer savings of over 20%.

In another development,

The MAC delivered to RAMKY has been supplied with multi-fuel capabilities, RAP (reclaimed asphalt pavement) processing abilities and other green features.

During the first phase of work at the recently opened Terminal 3 at Indira Gandhi International Airport, Delhi, which boasts the longest runway in Asia, Larsen & Toubro (L&T) produced over 650,000tonnes of asphalt in six months. It used two Marini MAP plants of 200tonnes and 260tonnes/hour capacity, the largest production capacity ever installed in India. The plants have been relocated to road projects in Gujarat and Tamil Nadu, two of India's 28 states.

Two 200tonnes/hour Marini plants have also been employed on work at Mumbai's Chhatrapati Shivaji International Airport, and other plants from the company are involved in work on most of the other new airports in India including international airports in Bangalore and Hyderabad.

Meanwhile, construction company

Over ten years ago, KMC took delivery of two Marini MAP 175s, and has since produced over 1.5 million tonnes of asphalt, having completed several road projects and been relocated many times.

One of the plants is now installed on the Pink City Expressway project, which involves six-laning 225.6km of the Gurgaon-Kotputli-Jaipur section of National Highway 8.