Earlier this year Shell Australia unveiled two major investments in bitumen facilities to help meet demand across eastern Australia.

February 20, 2012

Read time: 2 mins

Earlier this year Shell Australia unveiled two major investments in bitumen facilities to help meet demand across eastern Australia.

The investment will helpThe combined investment of AUD$27 million will create construction jobs in both Brisbane and Geelong, while increased supply will help service civil construction customers into the future.

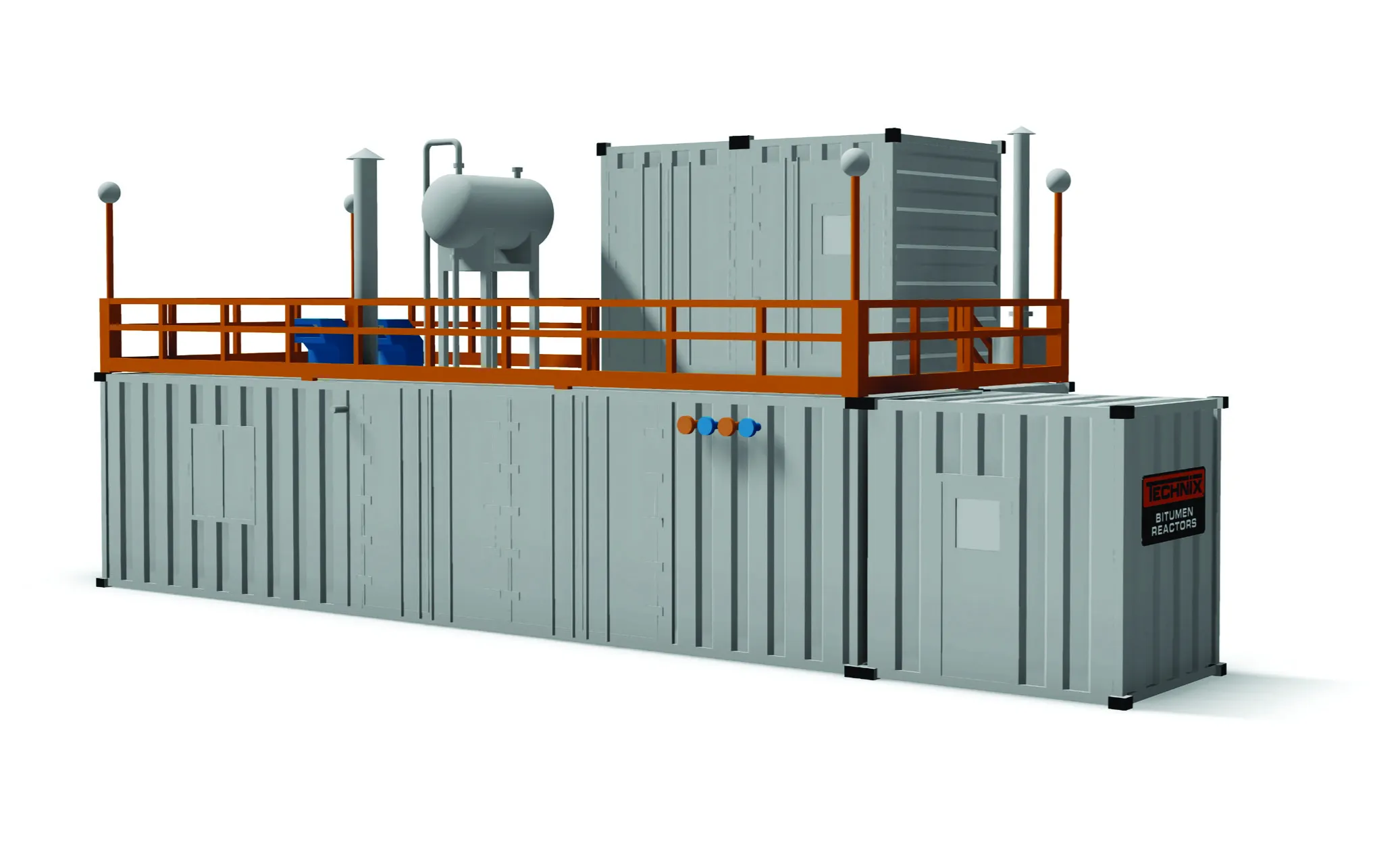

Shell's marketing general manager Craig James announced the construction of a new bitumen facility at Shell's Geelong Refinery, and an upgrade of existing facilities at the company's Pinkenba site on the Brisbane River.

He said the AUD$20 million (US$21 million) investment in Geelong would include four new hot bitumen tanks and a new road gantry for loading trucks.

The AUD$7 million ($7.3 million) investment in Shell's Pinkenba bitumen facility will take advantage of the import capability of Shell's new wharf on the Brisbane River, and will double the plant's capacity.

"We view bitumen as a key growth area for Shell's Australian business and these facilities will improve supply to civil contractor customers for many years to come," Mr James said.

"In a country as large as Australia there is a high demand for the bitumen used to construct roads, but we are expecting a spike in local demand caused by flood damage that will last for some years." He said that as well as expanding Shell's bitumen capacity, the upgrades will support local manufacture of specialty products such as Shell's Multiphalte range, a product used for Australian airport runway surfacing. The product was recently used on both Adelaide and Melbourne airport upgrades.

"Shell is working with civil contractors and road authorities across Australia to bring technologically advanced bitumen products to market," he said.

The bitumen investments are part of a much larger capital programme "to support Shell's aggressive plans to grow its marketing business in Australia."