Effective monitoring of aggregates stockpiles as well as face excavation can deliver greater quarrying efficiency

One of the latest innovations in quarrying is the use of drones, which provide major benefits for optimising operations. The use of affordable drone hardware and software solutions can help reduce stockpile inventory time by as much as 70%.

Through the recent partnership between

The use of drones over quarries has now moved from novelty to a routine event. A combination of simpler regulations, more affordable technology and integration with existing solutions has resulted in widespread use for common operations like stockpile and haul road inspections.

Quarries throughout Europe and the world are increasingly using drone data in their weekly or daily operations. Trimble and its partner Propeller are helping quarries with drone workflow adoption. "Propeller combines ease of use with powerful analysis tools that allow users to view 2D and 3D deliverables and extract valuable information," said Scott Crozier, director of marketing for Trimble Civil Engineering and Construction. "Like Trimble, Propeller understands the value of quality and accurate data for integration with civil engineering and construction workflows."

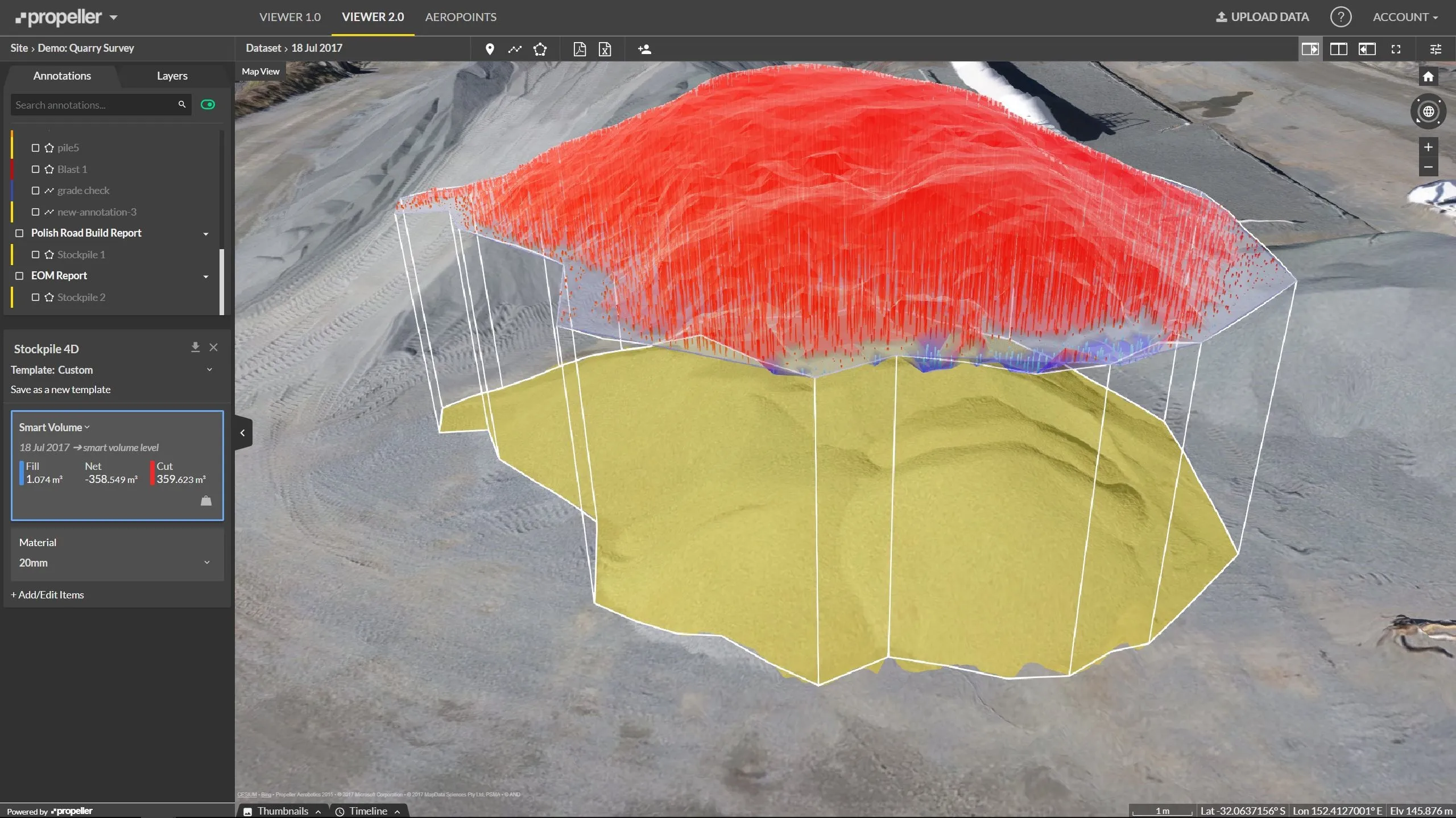

Stockpile management is among the most widely used worksite application for drones, and for good reason: drones have reduced the time taken to create a site wide stockpile inventory by up to 70%.

Using a drone and Propeller's cloud platform, a trained site worker can now capture the entire sales yard in less than 30 minutes and see the processed dataset within 24 hours. Within the platform, accurate volume calculations and comparisons can be generated in seconds, with all measurements easily exported to CSV files. What normally would take half a day can be completed in under an hour.

One quarry site now using Propeller was previously surveying its stockpiles from 6am to 2pm, in order to get the data ready for reporting the following morning. Now it can capture the entire yard with a drone in under 40 minutes, with the data available no later than the next day. Using the Propeller platform via a web browser, office staff measure the stockpiles on a 3D map constructed from the drone images. Each pile is accurately measured in less than a minute before exporting the inventory report to a spreadsheet within seconds.

One of the factors previously holding back drone adoption was uncertainty in accessing the drone data, aviation authority compliance and cost. Changes in aviation regulations throughout Europe have made it clearer and easier to fly drones in worksites. There is now a pool of employee and external drone operators that can fly a site safely without significant expense.

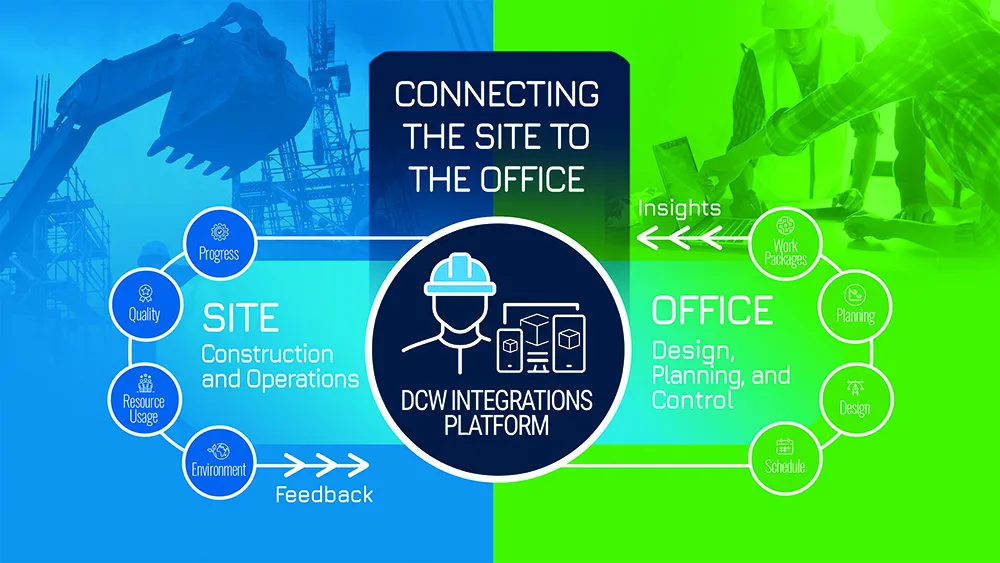

Pairing Propeller's web-based interface with Trimble Connected Site solutions allow users to properly utilise UAS information. It gives users access to simple tools to measure surface geometry, track trends and changes across time and perform visual inspections. Both technical and non-technical professionals are now able to gather insights remotely and collaborate, driving significant improvements in safety, efficiency and reducing environmental impact across a construction worksite.

Stockpile management is only one of the applications that quarries are using drones for in 2017. Others include surveying haul road for grade optimisation and safety, mobile fleet asset management and measuring blast performance. Just as GPS technology transformed surveying 20 years ago, drone-captured data is transforming inventory measurement today. Drone capture technology is maturing and accessible to all quarries. Far from being a novel approach, it is now an acceptable and reliable tool for monitoring and quarry inventory management.